- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Hot Pressed Boron Nitride

-

Purity:

-

99%

-

Color:

-

Light Grey

-

Density:

-

1.95-2.0g/cm3

-

Electrical Insulation:

-

Excellent

-

Max. working temp.(air condition):

-

900℃

-

Max. working temp.(vaccum condition):

-

1900℃

-

Max. working temp.(inert gas):

-

2100℃

Quick Details

-

Place of Origin:

-

Fujian, China

-

Model Number:

-

N/A

-

Brand Name:

-

N/A

-

Material:

-

Hot Pressed Boron Nitride

-

Purity:

-

99%

-

Color:

-

Light Grey

-

Density:

-

1.95-2.0g/cm3

-

Electrical Insulation:

-

Excellent

-

Max. working temp.(air condition):

-

900℃

-

Max. working temp.(vaccum condition):

-

1900℃

-

Max. working temp.(inert gas):

-

2100℃

|

Product Name

|

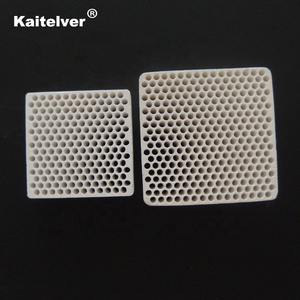

Heat Resistance Boron Nitride BN Ceramic Crucibles for Metal Melting

|

|

|

|

Material

|

99% Hot Pressed Boron Nitride/HPBN Ceramic/BN Ceramic

|

|

|

|

Color

|

Light Grey

|

|

|

|

Usage

|

Heat Resistant Crucibles for melting metals

|

|

|

|

Available Max. Size

|

420mm (length or width)

|

|

|

|

Available Shapes

|

rings, discs, rods, tubes, sleeves, bushings, shafts, rollers, balls, blocks etc

|

|

|

Hot Pressed Boron Nitride (HPBN) Ceramic is one of industrial ceramic materials, its hardness and mechanical strength is not as high as other Al2O3, ZrO2, Si34, SiC and AlN ceramics, so it is not suitable for mechanical applications. Its most famous features are in thermal and electrical applications and most applied as heat resistant parts or electrical insulators for various fields.

Main properties of Boron Nitride ceramics are:

●Good thermal shock resistance for sudden temperature change

●High thermal conductivity

●Low thermal expansion coefficient

●High temperature resistance (especially in inert gas or vacuum, up to around 2000℃)

●Good electrical insulation (breakdown strength is 4 times of Alumina Ceramics)

●Good chemical stability and no reaction with most molten metals like Cu, Stainless Steel, Fe, Sn, Zn and Sb etc.

●Good machinability, can be easily machined with normal metal tools

Mascera produces Boron Nitride materials with different composition:

●

99% Boron Nitride

●

BN + Ca

●

BN + Al2O3

●

BN + ZrO2

●

BN + AlN

|

Material Type

|

BN-99

|

BN + Ca

|

BN + Al2O3

|

BN + ZrO2

|

BN + AlN

|

|

Binder

|

B2O3

|

CaB2O4

|

AlBO3

|

B2O3

|

AlBO3

|

|

Density (g/cm

3

)

|

1.95-2.0

|

2.0-2.1

|

2.25-2.35

|

2.9-3.0

|

2.5-2.6

|

|

Flexural Strength (Mpa)

|

30

|

35

|

85

|

120

|

110

|

|

Compressive Strength (Mpa)

|

58

|

70

|

150

|

200

|

185

|

|

Electrical Resistivity (Ω.cm)

|

>10

14

|

>10

13

|

>10

12

|

>10

12

|

>10

13

|

|

Max. Service Temp. (℃)

@air condition |

900

|

900

|

1000

|

1000

|

1000

|

|

Max. Service Temp. (℃)

@vacuum condiction |

1900

|

1900

|

1700

|

1800

|

1800

|

|

Max. Service Temp. (℃)

@inert gas condition |

2100

|

2100

|

1700

|

1800

|

1800

|

|

Thermal Conductivity (W/mk)

|

30

|

32

|

35

|

30

|

55

|

|

Thermal Expansion Coefficient

(25 - 1000℃) (10-6/k) |

1.5

|

1.6

|

1.9

|

6.0

|

3.0

|

Typical Applications of Boron Nitride parts are:

●Electrical Insulating parts for vacuum furnace/polysilicon ingot furnace/semiconductor device

●Crucibles or containers for high purity molten metals

●Break rings for continuous casting of metals

●Ceramic nozzles for metal powder gas atomization

●Heat resistant ceramic parts

We have completed production lines for molding, sintering, high precision machining, quality inspection of technical ceramic components. Our products are in conformity with ISO9001:2015 quality management system and we are capable to deliver ceramic components of fully dense, accurate size and surface finish control, prompt lead time.

Since our foundation, Mascera has committed to providing ceramic components of highest quality and has built faithful partnership with our customers. Currently, our products have been exported to more than 30 countries and widely applied in industries like machinery, automotive, chemistry, medical, energy, electronic, semiconductor, aerospace, telecommunication etc.

A: MOQ will differ in material, size, machining difficulty, we will let you know MOQ for each part when inquiry.

Q2: Can i get a sample for test?

A: For ceramic parts we have in stock, we can provide free sample if goods value is not high; for ceramic parts which is newly developed, mold cost or sample cost will be needed.

Q3. Can you produce according to the samples or drawings?

A: Yes. most of our ceramic parts are customized, we have rich experience in tailor-made parts. We have capability to control the parts in required size accuracy and surface finish

Q4. How can i pay to you?

A: We accept payment of T/T, credit card, Western Union, Paypal.Payment terms is 50% payment in advance and 50% before shipment.

Q5. Can i get a replacement for damaged or defected products?

A: Yes, we will remake new products for you when damage or defect are found, if you could not wait for extra time, we will refund to you or issue a credit to use in future orders.