- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

xrido

-

Voltage:

-

220V/380V/415V/600V or customized

-

Dimension(L*W*H):

-

2800x1300x1850

-

Power (kW):

-

22

-

Weight (T):

-

2200

-

Name:

-

Plastic shredder machine

-

Function:

-

plastic crusher

-

knife diameter:

-

500 mm

-

knife Qty:

-

20PCS

-

capacity:

-

15-18T/h

-

outcomes:

-

100*100 mm

-

knife material:

-

9SiCr

-

Crushing material:

-

Types Waste Plastic

-

Product name:

-

Shreddder Machine

-

Color:

-

Customized Color

Quick Details

-

Max.Production Capacity (kg/h):

-

10000

-

Place of Origin:

-

Henan, China

-

Production Capacity (kg/h):

-

15000 - 18000 kg/h

-

Brand Name:

-

xrido

-

Voltage:

-

220V/380V/415V/600V or customized

-

Dimension(L*W*H):

-

2800x1300x1850

-

Power (kW):

-

22

-

Weight (T):

-

2200

-

Name:

-

Plastic shredder machine

-

Function:

-

plastic crusher

-

knife diameter:

-

500 mm

-

knife Qty:

-

20PCS

-

capacity:

-

15-18T/h

-

outcomes:

-

100*100 mm

-

knife material:

-

9SiCr

-

Crushing material:

-

Types Waste Plastic

-

Product name:

-

Shreddder Machine

-

Color:

-

Customized Color

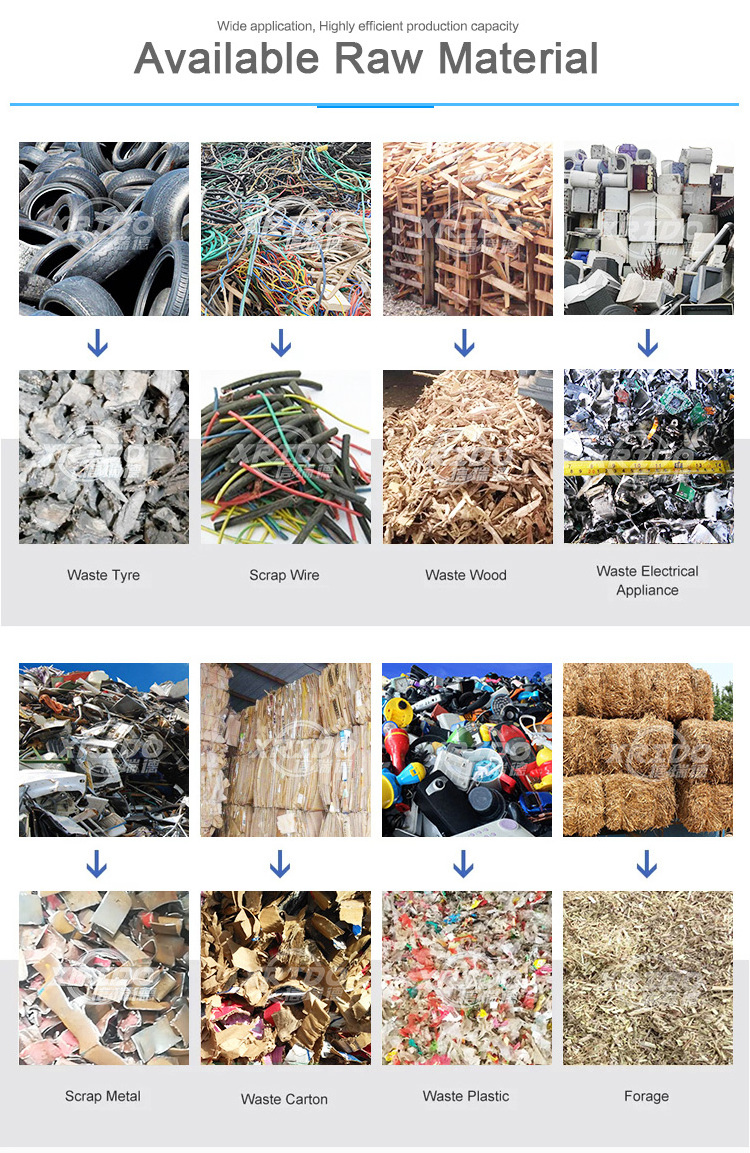

Products Description

The

double shaft shredder

have been designed for a wide array of applications and industries, suitable for shredding solid material such as E-waste, metal,wood, plastic,scrap tires, packaging barrel, pallets,etc. Depending on input material and the following process the shredded material can be used directly or go into the next step of size reduction. It is widely used in industry waste recycling, electronic recycling, pallet recycling,municipal solid waste recycling,plastic recycling,tire recycling,paper making industry and etc.

Biaxial shredders

use two-axis independent drive,so that the production of materials to produce the corresponding pressure, to achieve automatic feeding function,a unique knife shaft structure and four-corner rotary tool,low speed high torque in the production process, There will be no winding shaft,or stuck phenomenon of the device,thereby increasing the production efficiency,the device is suitable for all kinds of toughness, high viscosity material crushing.

Details Images

Product Paramenters

Appliance : waste steel parts: Steel barrel, waste bike , scrap cars , used car body , light metal , motor bicycle , waste square steel , metal pipe etc .

waste appliance parts: waste refrigerator scrap , used TV sets , waste air conditioner , micro woven , PCB board etc.

wood part : wood branch , furniture scrap , desk , chair , bed , mattress etc.

Paper waste part: magazine scrap , book waste , industrial carton box , used newspaper etc.

industrial scrap part: leather scrap , cloth, industrial packages , used cloth yard etc.

waste appliance parts: waste refrigerator scrap , used TV sets , waste air conditioner , micro woven , PCB board etc.

wood part : wood branch , furniture scrap , desk , chair , bed , mattress etc.

Paper waste part: magazine scrap , book waste , industrial carton box , used newspaper etc.

industrial scrap part: leather scrap , cloth, industrial packages , used cloth yard etc.

|

Model

|

Size(LxWxH)(mm)

|

Feed inlet size(mm)

|

blade diameter(mm)

|

Power(kw)

|

|

SZ-500

|

2800x1300x1850

|

500x480

|

200

|

11x2

|

|

SZ-800

|

3000x1300x1850

|

800x480

|

200

|

15x2

|

|

SZ-1000

|

3300x1900x2200

|

1000x690

|

300

|

22x2

|

|

SZ-1200

|

3600x2000x2200

|

1200x690

|

300

|

30x2

|

|

SZ-1500

|

4180x2100x2400

|

1500x850

|

550

|

55x2

|

|

SZ-1800

|

5800x2400x3300

|

1800x1206

|

550

|

75x2

|

|

SZ-2000

|

7500x3200x3800

|

2000x1490

|

600

|

90x2

|

Our Advantages

1. Super high crushing efficiency

Hydraulic feeding, hammer throwing and ring hammer combined crushing hammer head can improve the efficiency of other crusher

equipment by 5% - 15%.

2. Perfect finished granules

The unique roller rubbing process can significantly remove the paint and other contaminants, form high-density pellets and

improve the grade of crushing materials.

3. Stable operation capability

When the safety door is set, after the non-breakable material enters the crushing chamber, the operator can open the safety door

and discharge it from the body to avoid damaging the crusher.

4. Intelligent Control System

PLC control system and hydraulic power system can save time and labor in intelligent production and realize stable, automatic and

safe operation of the whole production line.

Hydraulic feeding, hammer throwing and ring hammer combined crushing hammer head can improve the efficiency of other crusher

equipment by 5% - 15%.

2. Perfect finished granules

The unique roller rubbing process can significantly remove the paint and other contaminants, form high-density pellets and

improve the grade of crushing materials.

3. Stable operation capability

When the safety door is set, after the non-breakable material enters the crushing chamber, the operator can open the safety door

and discharge it from the body to avoid damaging the crusher.

4. Intelligent Control System

PLC control system and hydraulic power system can save time and labor in intelligent production and realize stable, automatic and

safe operation of the whole production line.

Why Choose Us

1. Super high crushing efficiency

Hydraulic feeding, hammer throwing and ring hammer combined crushing hammer head can improve the efficiency of other crusher equipment by 5% - 15%.

2. Perfect finished granules

The unique roller rubbing process can significantly remove the paint and other contaminants, form high-density pellets and improve the grade of crushing materials.

3. Stable operation capability

When the safety door is set, after the non-breakable material enters the crushing chamber, the operator can open the safety door and discharge it from the body to avoid damaging the crusher.

4. Intelligent Control System

PLC control system and hydraulic power system can save time and labor in intelligent production and realize stable, automatic and safe operation of the whole production line.

Hydraulic feeding, hammer throwing and ring hammer combined crushing hammer head can improve the efficiency of other crusher equipment by 5% - 15%.

2. Perfect finished granules

The unique roller rubbing process can significantly remove the paint and other contaminants, form high-density pellets and improve the grade of crushing materials.

3. Stable operation capability

When the safety door is set, after the non-breakable material enters the crushing chamber, the operator can open the safety door and discharge it from the body to avoid damaging the crusher.

4. Intelligent Control System

PLC control system and hydraulic power system can save time and labor in intelligent production and realize stable, automatic and safe operation of the whole production line.

Exhibition

Hot Searches