- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

10~120m/min

-

Place of Origin:

-

China

-

Voltage:

-

220/380/415/420/440V

-

Power:

-

45kw

-

Weight:

-

15000 kg

-

Name:

-

Round Square Rectangular ERW Tube mills

-

Pipe diameter:

-

50~141.3mm

-

pipe thickness:

-

1.2~6.0mm

-

Usage:

-

making ERW pipe

-

After-sell service:

-

On-site installation and debugging

-

Useful life:

-

30 Years

-

Export Port:

-

Shanghai Port

-

Cutting system:

-

cold or hot flying saw

-

Control system:

-

PLC(imported Brand)

-

Certification:

-

CE,ISO9001

Quick Details

-

Pipe Material:

-

Carbon steel

-

Applicable Industries:

-

steel pipe making machine

-

Marketing Type:

-

Hot Product 2022

-

Production Capacity:

-

10~120m/min

-

Place of Origin:

-

China

-

Voltage:

-

220/380/415/420/440V

-

Power:

-

45kw

-

Weight:

-

15000 kg

-

Name:

-

Round Square Rectangular ERW Tube mills

-

Pipe diameter:

-

50~141.3mm

-

pipe thickness:

-

1.2~6.0mm

-

Usage:

-

making ERW pipe

-

After-sell service:

-

On-site installation and debugging

-

Useful life:

-

30 Years

-

Export Port:

-

Shanghai Port

-

Cutting system:

-

cold or hot flying saw

-

Control system:

-

PLC(imported Brand)

-

Certification:

-

CE,ISO9001

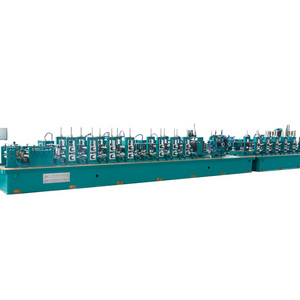

Round Square Rectangular ERW Tube mills

Products of Tube Mill Production Line

1. TUBE MILL ENTRY SECTION

2. HORIZONTAL LOOP ACCUMULATOR

3. TUBE FORMING AND SIZING SECTION

4. FLYING SAW CUT OFF EQUIPMENT

5. CONVEYOR TABLE

6. AUTOMATIC STACKING & PACKAGING MACHINE

Features of

ERW tube mill machine

:

Durable and non-deformed machine base

Use thick steel to weld together as a whole to tempering more than 4 hours twice to make sure that the machine can be used in long term without deformation.

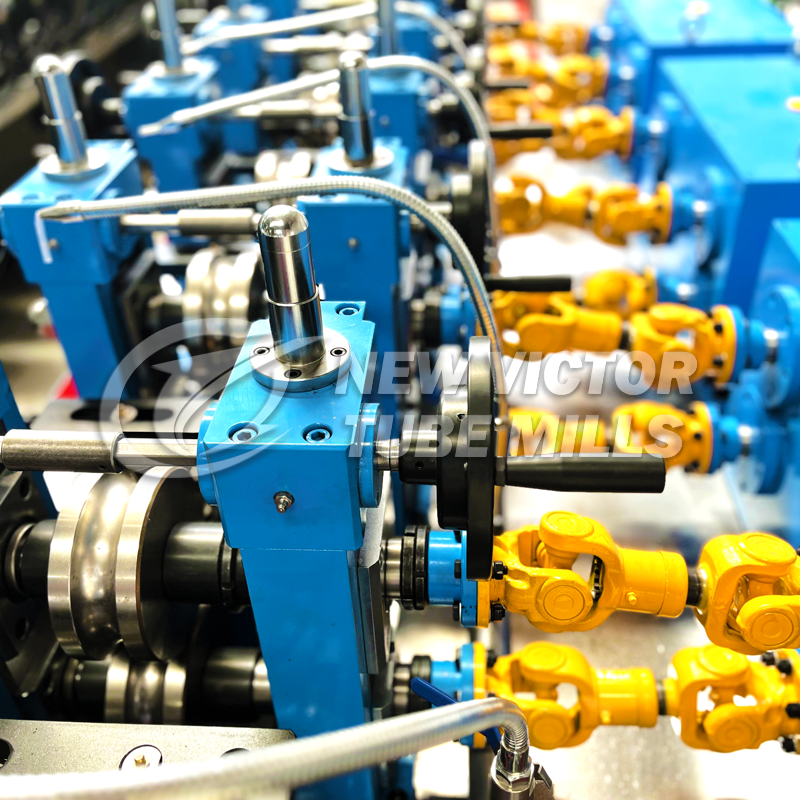

Stable transmission system

Spiral bevel gear, drum gear coupling and carburization and quenching for gear teeth makes the driving system stable, efficient

and wearable, with higher loading capacity and lower noise

and wearable, with higher loading capacity and lower noise

Long bearing life

Equipped with greasing nozzles for the bearing lubrication, the bearing life is largely improved.

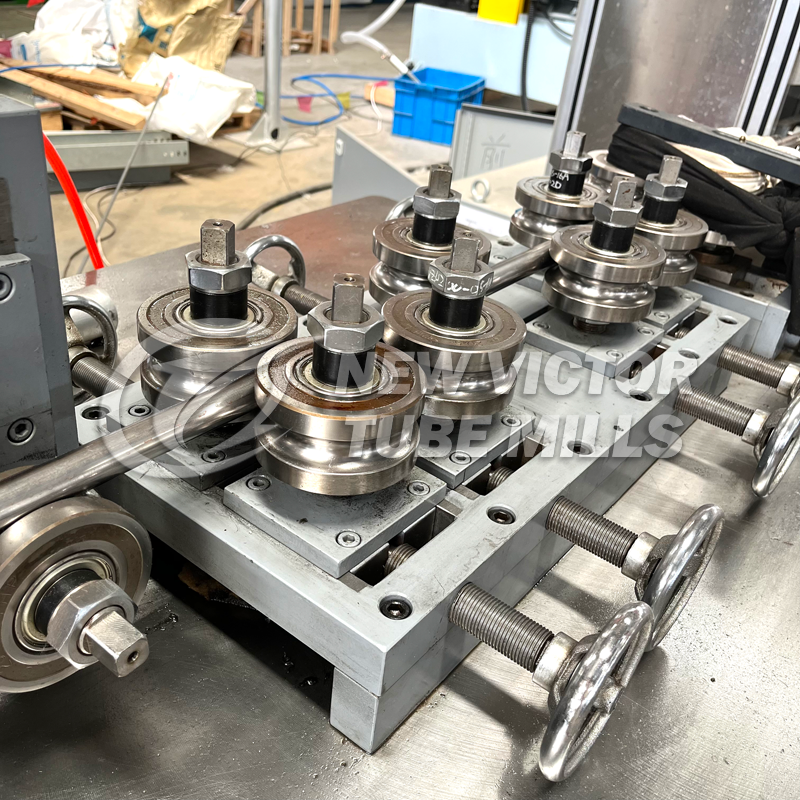

Automatic roller quick change system

Online and automatic roller quickly change system, change roller in 10 minutes, resume production in 20 minutes.

Roller Quick Change System

Roller Quick Change Type Tube Mill Machine

Roller Quick Change Type Pipe Mill Machine

Advantages of Roller Quick Change System

with this system, you can change the roller in 10 minutes and resume production in 20 minutes. one machine can easily produce pipes pf many sizes.

ROLLER QUICK CHANGE SYSTEM

Product Paramenters

|

Model

|

Tube O.D. (mm)

|

Wall Thickness (mm)

|

Square/Rectangle (mm)

|

Wall Thickness (mm)

|

Speed

(m/min)

|

Main motor

(KW)

|

|

VZH-12

|

4 ~ 12

|

0.2 ~ 0.5

|

--

|

--

|

30 ~ 120

|

15

|

|

VZH-16

|

6 ~ 16

|

0.2 ~ 0.8

|

--

|

--

|

30 ~ 120

|

22

|

|

VZH-20

|

7 ~ 20

|

0.2 ~ 1.0

|

--

|

--

|

30 ~ 120

|

30

|

|

VZH-25

|

9 ~ 25.4

|

0.25 ~ 1.2

|

--

|

--

|

30 ~ 120

|

37(22*2)

|

|

VZH-32

|

10 ~ 32

|

0.25 ~ 1.5

|

8*8 ~25.4*25.4

10*6 ~ 31.8*19.1

|

0.25 ~ 1.2

|

30 ~ 120

|

45(30*2)

|

|

VZH-32z

|

|

0.5 ~ 2.0

|

|

0.5 ~ 1.5

|

30 ~ 100

|

55(37*2)

|

|

VZH-40

|

12.7 ~ 40

|

0.3 ~ 1.8

|

10*10 ~31.8*31.8

20*10 ~ 40*20 |

0.3 ~ 1.5

|

30 ~ 110

|

75

|

|

VZH-40z

|

|

0.6 ~ 2.0

|

|

0.6 ~ 1.5

|

30 ~ 100

|

45*2

|

|

VZH-50q

|

16 ~ 50.8

|

0.4 ~ 1.5

|

12.7*12.7 ~40*40

20*10 ~ 50*25 |

0.4 ~ 1.2

|

30 ~ 110

|

90

|

|

VZH-50

|

|

0.5 ~ 2.0

|

|

0.5 ~ 1.5

|

30 ~ 90

|

45*2(110)

|

|

VZH-50z

|

|

0.7 ~ 2.5

|

|

0.7 ~ 2.0

|

30 ~ 80

|

55*2

|

|

VZH-63q

|

19.05 ~ 63.5

|

0.6 ~ 2.0

|

15*15 ~50*50

20*10 ~ 60*30 |

0.6 ~ 1.5

|

30 ~ 90

|

132(55*2)

|

|

VZH-63

|

|

0.7 ~ 3.0

|

|

0.7 ~ 2.5

|

30 ~ 80

|

75*2(132)

|

|

VZH-63z

|

|

0.8 ~ 3.5

|

|

0.8 ~ 3.0

|

20 ~ 70

|

90*2

|

|

VZH-76q

|

25.4 ~ 76.2

|

0.8 ~ 2.5

|

20*20 ~60*60

30*15 ~ 80*40 |

0.8 ~ 2.0

|

30 ~ 90

|

160(75*2)

|

|

VZH-76

|

|

0.8 ~ 3.5

|

|

0.8 ~ 3.0

|

30 ~ 80

|

90*2

|

|

VZH-76z

|

|

0.8 ~ 4.0

|

|

0.8 ~ 3.5

|

20 ~ 70

|

|

|

VZH-90q

|

30 ~ 90

|

0.8 ~ 3.0

|

25*25 ~70*70

30*20 ~ 80*40 |

0.8 ~ 2.5

|

30 ~ 90

|

180(90*2)

|

|

VZH-90

|

|

0.8 ~ 3.5

|

|

0.8 ~ 3.0

|

30 ~ 80

|

110*2(132*2)

|

|

VZH-90z

|

|

1.0 ~ 4.0

|

|

1.0 ~ 3.5

|

20 ~ 70

|

|

|

VZH-100q

|

31.8 ~ 101.6

|

1.0 ~ 3.0

|

25*25 ~80*80

30*20 ~ 100*50 |

1.0 ~ 2.5

|

30 ~ 90

|

200(110*2)

|

|

VZH-100

|

|

1.0 ~ 3.75

|

|

1.0 ~ 3.25

|

30 ~ 80

|

110*2

|

|

VZH-100z

|

|

1.0 ~ 4.25

|

|

1.0 ~ 3.5

|

20 ~ 70

|

132*2

|

|

VZH-114q

|

35 ~ 114.3

|

1.0 ~ 3.0

|

30*30 ~90*90

40*20 ~ 120*60 |

1.0 ~ 2.5

|

20 ~ 80

|

110*2

|

|

VZH-114

|

|

1.2 ~ 4.5

|

|

1.2 ~ 4.0

|

20 ~ 70

|

132*2

|

|

VZH-114z

|

40 ~ 114.3

|

1.2 ~ 5.0

|

|

1.2 ~ 4.5

|

15 ~ 60

|

|

|

VZH-127q

|

40 ~ 127

|

1.2 ~ 3.5

|

40*40 ~100*100

60*30 ~ 120*80 |

1.2 ~ 3.0

|

20 ~ 70

|

132*2

|

|

VZH-127

|

|

1.5 ~ 5.0

|

|

1.5 ~ 4.5

|

15 ~ 60

|

160*2

|

|

VZH-127z

|

50 ~ 127

|

1.5 ~ 5.5

|

|

1.5 ~ 5.0

|

10 ~ 45

|

160*2

|

|

VZH-140q

|

50 ~ 141.3

|

1.2 ~ 4.0

|

50*50 ~110*110

60*40 ~ 150*75 |

1.2 ~ 3.5

|

15 ~ 60

|

160*2

|

|

VZH-140

|

|

1.5 ~ 5.5

|

|

1.5 ~ 5.0

|

10 ~ 50

|

180*2

|

|

VZH-140z

|

60 ~ 141.3

|

2.0 ~ 6.0

|

|

2.0 ~ 5.5

|

10 ~ 40

|

180*2

|

|

VZH-168q

|

60 ~ 168.3

|

1.5 ~ 5.0

|

60*60 ~130*130

80*40 ~ 160*80 |

1.5 ~ 4.5

|

10 ~ 50

|

180*2

|

|

VZH-168

|

|

2.0 ~ 6.0

|

|

2.0 ~ 5.5

|

10 ~ 50

|

200*2

|

|

VZH-168z

|

76.2 ~ 168.3

|

2.5 ~ 8.0

|

|

2.5 ~ 7.0

|

10 ~ 40

|

200+132*2

(132*4)

|

|

VZH-219q

|

89.1 ~ 219.1

|

2.0 ~ 6.0

|

70*70 ~160*160

100*50 ~200*100 |

2.0 ~ 5.5

|

10 ~ 50

|

110*2+132*2

|

|

VZH-219

|

|

3.0 ~ 8.0

|

|

3.0 ~ 7.0

|

10 ~ 40

|

132*2+132*2

|

|

VZH-219z

|

|

4.0 ~ 10.0

|

|

4.0 ~ 9.0

|

10 ~ 40

|

132*2+160*2

|

|

VZH-273

|

114.3 ~ 273

|

4.0 ~ 10.0

|

90*90 ~200*200

120*60 ~260*130 |

4.0 ~ 9.0

|

10 ~ 40

|

160*2+160*2

|

|

VZH-273z

|

|

4.5 ~ 12.0

|

|

4.5 ~ 11.0

|

10 ~ 35

|

180*4

|

Classic Case

VZH-168 in Palestine

OD precision can be controlled within ±0.02mm, oval tolerance to be ±0.02mm also, straightness ≤0.8mm/m.

The production line also designed to be high strength, CNC high precision for the roller stands of forming section, sizing section and straightening section, strict precision assembling also.

The production line also designed to be high strength, CNC high precision for the roller stands of forming section, sizing section and straightening section, strict precision assembling also.

High speed ERW tube mill lines in Cambodia

High speed ERW tube mill lines installed in Cambodia with online Zinc spraying for galvanized pipes of construction, guardrail, shelf and etc. Speed can reach 40-120M/min for diameter range 15~50mm.

Meanwhile for the plastic covered galvanized pipes of water, gas and natural gas transportation, highly stable welding seam, no leakage, to be qualified above 99%.

The roller quick change system enables roller changes in 10 minutes and resumes production in 20 minutes.

Meanwhile for the plastic covered galvanized pipes of water, gas and natural gas transportation, highly stable welding seam, no leakage, to be qualified above 99%.

The roller quick change system enables roller changes in 10 minutes and resumes production in 20 minutes.

Company Introduction

Jiangsu New Victor Industrial Co., Ltd. founded in 1992, is a professional manufacturer of welding pipe machinery. over the years the company is committed to research and development and production of high frequency straight seam tube mill line, steel ball rolling mill machine, copper clad aluminum equipment, slitting machine and other metallurgical machinery.

As the main research and development of the company, VZH series of high frequency straight seam tube mill machine has more than 20 patents, and passed the CE, SGS, ISO and other international certification. We currently supply more than 2000 pipe mill lines to more than 90 countries and are expanding. We have a professional team of more than 200 people, including more than 30 high-end engineers and more than 20 after-sales service team. From consulting to order confirmation, from production to after-sales on-site installation training, we strive to ensure that everything we do is of the highest quality.

As the main research and development of the company, VZH series of high frequency straight seam tube mill machine has more than 20 patents, and passed the CE, SGS, ISO and other international certification. We currently supply more than 2000 pipe mill lines to more than 90 countries and are expanding. We have a professional team of more than 200 people, including more than 30 high-end engineers and more than 20 after-sales service team. From consulting to order confirmation, from production to after-sales on-site installation training, we strive to ensure that everything we do is of the highest quality.

Our Service

Pre-sale service

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory, we can show you the running machine in China.

After-sales service

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions, Our fast and professional aftersales service engineer team will go to your factory

to install the machine, give you the operating manual, And train your employee until they can operate the machine well.

3.We provide one year warranty and life-long technical support.

4.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

5 .24 hours for engineer response.

6.Your business relationship with us will be confidential to any third party.

7. We offer one year's supply of spare parts free of charge

Quality Control

We have the single quality department, that make sure the material of the raw materials is good, and ensure the machine running smoothly.

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory, we can show you the running machine in China.

After-sales service

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions, Our fast and professional aftersales service engineer team will go to your factory

to install the machine, give you the operating manual, And train your employee until they can operate the machine well.

3.We provide one year warranty and life-long technical support.

4.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

5 .24 hours for engineer response.

6.Your business relationship with us will be confidential to any third party.

7. We offer one year's supply of spare parts free of charge

Quality Control

We have the single quality department, that make sure the material of the raw materials is good, and ensure the machine running smoothly.

FAQ

Are you a trading company or a manufactory?

We are a manufactory with 30 years experience, we supply the factory price with good quality, welcome to visit !

Do you have reference project?

We have reference project in most countries, If we get the permission of the customer who has brought the machines from us ,we can tell you their contact information, you can go to visit their factory. And you are always welcome to come to visit our company, and see the machine running in our factory, we can pick you up from the station near our city. Contact our foreign sale team you can get video of our reference running machine.

Do you provide turnkey project?

Turnkey project available We can help you to start a new company in steel tube making.

Do you have agent and after-service stations?

So far we have agent in the middle east, Ethiopia, Singapore, South America. welcome to join us!

When can I get my machine after I paid?

Normally production time is around 60~90days, the exactly depend on what kind of machine you order. The shipping time is based on your destination port.

When can i get engineers from you?

When you finish the Preparation conditions(water resource, electricity, air supply, production materials)contact with our sales people we will dispatch engineer to install the machine for you ,and train your employees to use the machine well. Normally when your preparation is done, you can contact with our sales people and cooperate us to get the visa for the engineer and our engineer will be there within 15 days.

How long time for installation?

According your machines order, we will send one or two engineers to your plant, it will take about 10 days to 25 days.

How about the spare parts?

We will send one year enough easy broken spare parts together with the machines, shipping together.

Do you have any certificate?

We have CE, ISO, SGS certification

Do you provide customized service?

We can design the machines according your requirements.

What’s your guarantee or the warranty of the quality if we buy your machines?

We offer you high quality machines with 1 year guarantee and supply life-long technical support.

We are a manufactory with 30 years experience, we supply the factory price with good quality, welcome to visit !

Do you have reference project?

We have reference project in most countries, If we get the permission of the customer who has brought the machines from us ,we can tell you their contact information, you can go to visit their factory. And you are always welcome to come to visit our company, and see the machine running in our factory, we can pick you up from the station near our city. Contact our foreign sale team you can get video of our reference running machine.

Do you provide turnkey project?

Turnkey project available We can help you to start a new company in steel tube making.

Do you have agent and after-service stations?

So far we have agent in the middle east, Ethiopia, Singapore, South America. welcome to join us!

When can I get my machine after I paid?

Normally production time is around 60~90days, the exactly depend on what kind of machine you order. The shipping time is based on your destination port.

When can i get engineers from you?

When you finish the Preparation conditions(water resource, electricity, air supply, production materials)contact with our sales people we will dispatch engineer to install the machine for you ,and train your employees to use the machine well. Normally when your preparation is done, you can contact with our sales people and cooperate us to get the visa for the engineer and our engineer will be there within 15 days.

How long time for installation?

According your machines order, we will send one or two engineers to your plant, it will take about 10 days to 25 days.

How about the spare parts?

We will send one year enough easy broken spare parts together with the machines, shipping together.

Do you have any certificate?

We have CE, ISO, SGS certification

Do you provide customized service?

We can design the machines according your requirements.

What’s your guarantee or the warranty of the quality if we buy your machines?

We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Hot Searches