- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

visbella

-

Product name:

-

Exhaust pipe repair cement

-

Appearance:

-

Cream paste

-

Resistant to:

-

Fumes,dilute acids,water,chemical

-

Color:

-

Black,white,gray

-

High Temperature Resist:

-

up to +1100℃

-

HS CODE:

-

3506990000

-

Certificate:

-

RoHs, REACH, S G S, BSCI, ISO

-

Full cure time:

-

24 hours

-

Warranty:

-

12 months

-

Sample:

-

Yes

Quick Details

-

Type:

-

exhaust system sealer

-

Weight:

-

75g 150g

-

Expiration Date:

-

12 months

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

visbella

-

Product name:

-

Exhaust pipe repair cement

-

Appearance:

-

Cream paste

-

Resistant to:

-

Fumes,dilute acids,water,chemical

-

Color:

-

Black,white,gray

-

High Temperature Resist:

-

up to +1100℃

-

HS CODE:

-

3506990000

-

Certificate:

-

RoHs, REACH, S G S, BSCI, ISO

-

Full cure time:

-

24 hours

-

Warranty:

-

12 months

-

Sample:

-

Yes

Product Description

Visbella® Exhaust System Sealer used for leaks in mufflers,tailpipes and around joints. Saves the cost of expensive muffler system replacement. Also makes new installation more secure. Sets like a weld, remarkable adhesion to clean or rusted surfaces. Resistant to monoxide gases and high temperatures.

Advantage&Features

●Saves Energy

● Applies Easily

● Stops Air Leaks

● Sets Rock Hard When Heated

● Super Tough, High Temperature Mortar

● Applies Easily

● Stops Air Leaks

● Sets Rock Hard When Heated

● Super Tough, High Temperature Mortar

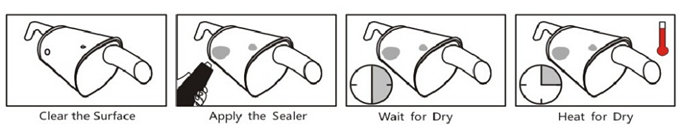

How to Use

Precautions

1. Surfaces must be clean, dry and free of dirt, grease or oil.

2. Wet the surface to be repaired with water.

3. Apply the Sealer directly over the hole.

4. Allow to dry for 30 minutes and start engine to run for at least 10 minutes.

5. For new installations, apply the Gum around inside of the larger pipe. Complete and seal the connection.

6. Clear up with water prior to material drying.

1. Surfaces must be clean, dry and free of dirt, grease or oil.

2. Wet the surface to be repaired with water.

3. Apply the Sealer directly over the hole.

4. Allow to dry for 30 minutes and start engine to run for at least 10 minutes.

5. For new installations, apply the Gum around inside of the larger pipe. Complete and seal the connection.

6. Clear up with water prior to material drying.

Hot Searches