- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

450KW

-

Weight:

-

3500 KG

-

Dimension(L*W*H):

-

8900*3900*2800mm

-

Function:

-

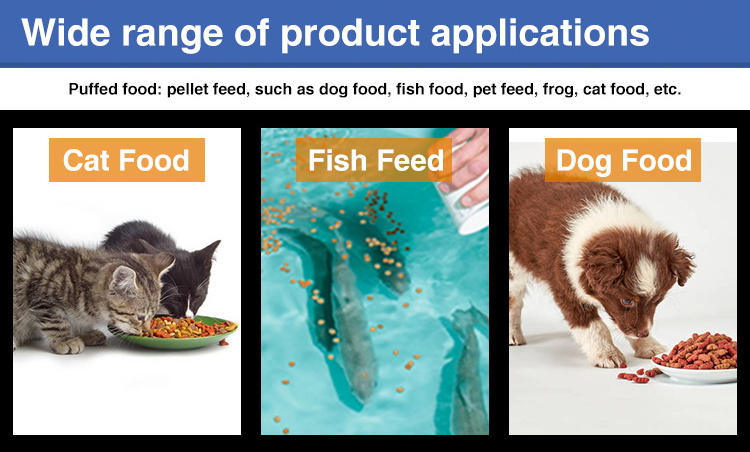

to produce cat food and dog food

-

Raw material:

-

Maize,wheat bran and so on

-

Application for:

-

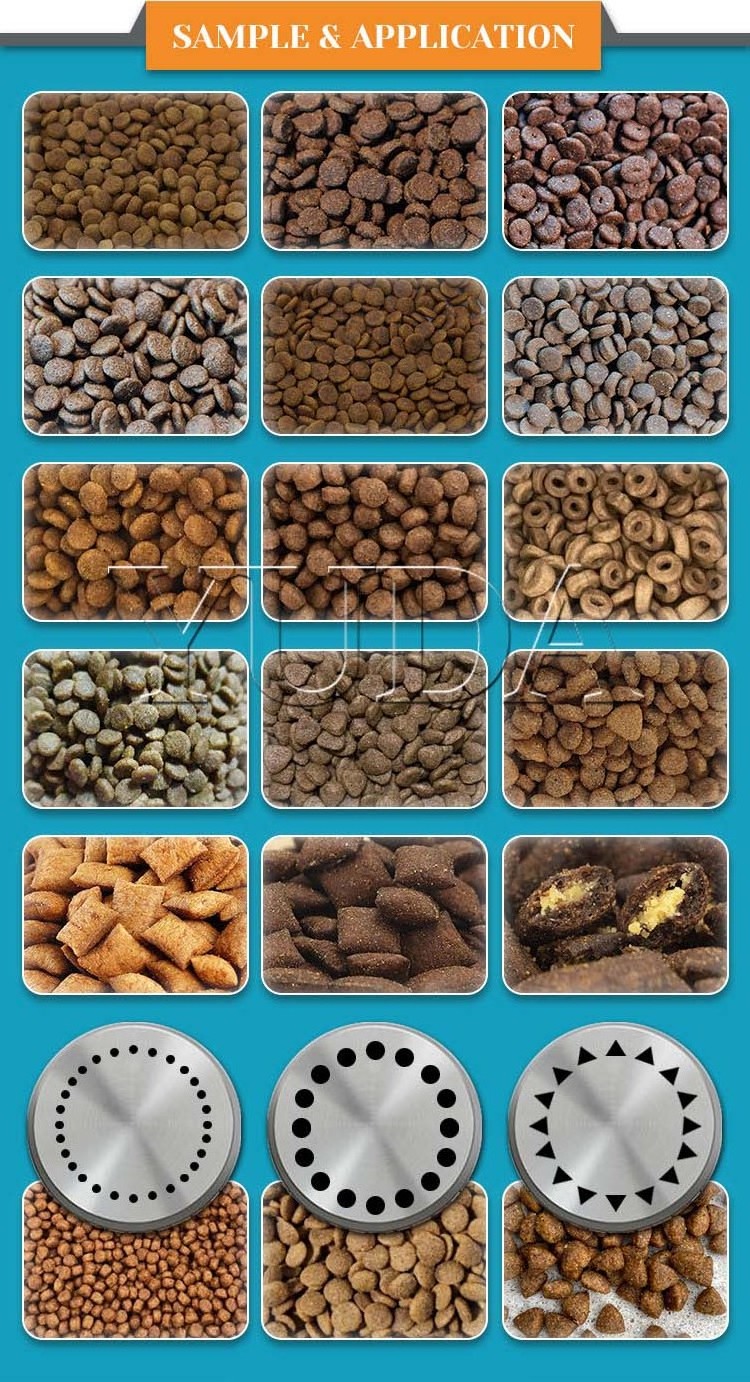

pet food,dog food,cat food,fish feed,shrimp feed

-

material:

-

stainless steel food grade

-

Motor brand:

-

Simense BEIDE or Chinese Brand

-

craft:

-

twin screw extruder

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

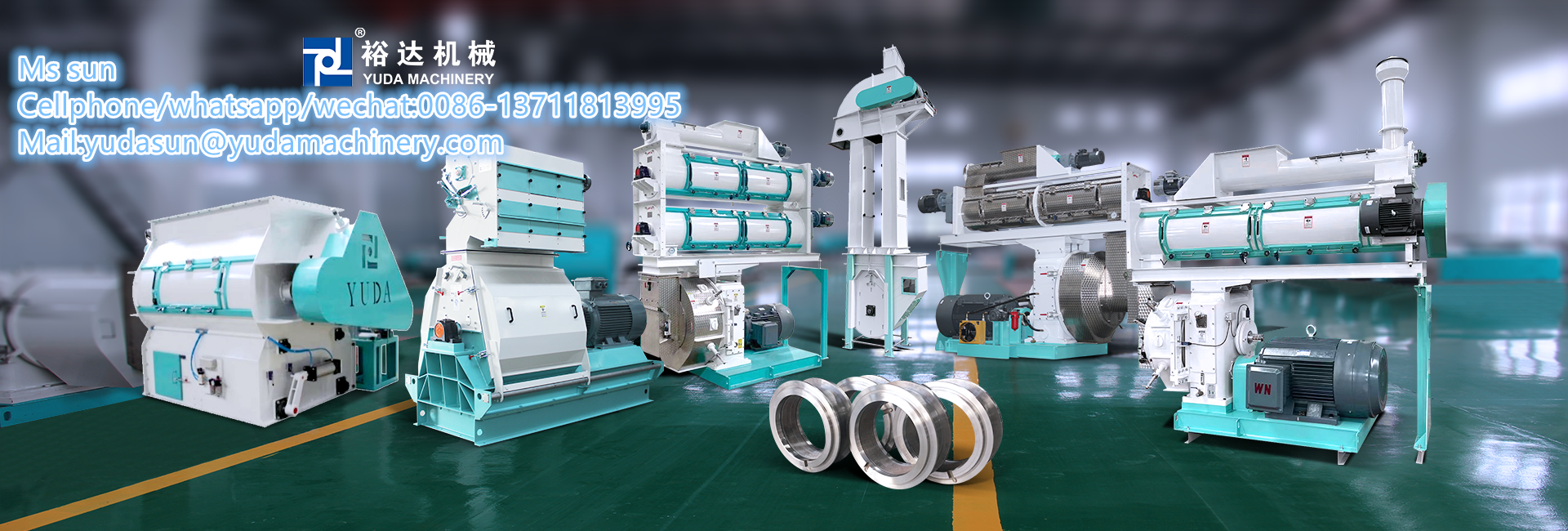

YUDA

-

Voltage:

-

380v

-

Power:

-

450KW

-

Weight:

-

3500 KG

-

Dimension(L*W*H):

-

8900*3900*2800mm

-

Function:

-

to produce cat food and dog food

-

Raw material:

-

Maize,wheat bran and so on

-

Application for:

-

pet food,dog food,cat food,fish feed,shrimp feed

-

material:

-

stainless steel food grade

-

Motor brand:

-

Simense BEIDE or Chinese Brand

-

craft:

-

twin screw extruder

10-15 ton/h Custom Design Automatic Dog Cat Fish Pet Food Making Machine Processing Extruder Production Line

Product Description

General Description for

10-15 ton/h Custom Design Automatic Dog Cat Fish Pet Food Making Machine Processing Extruder Production Line

:

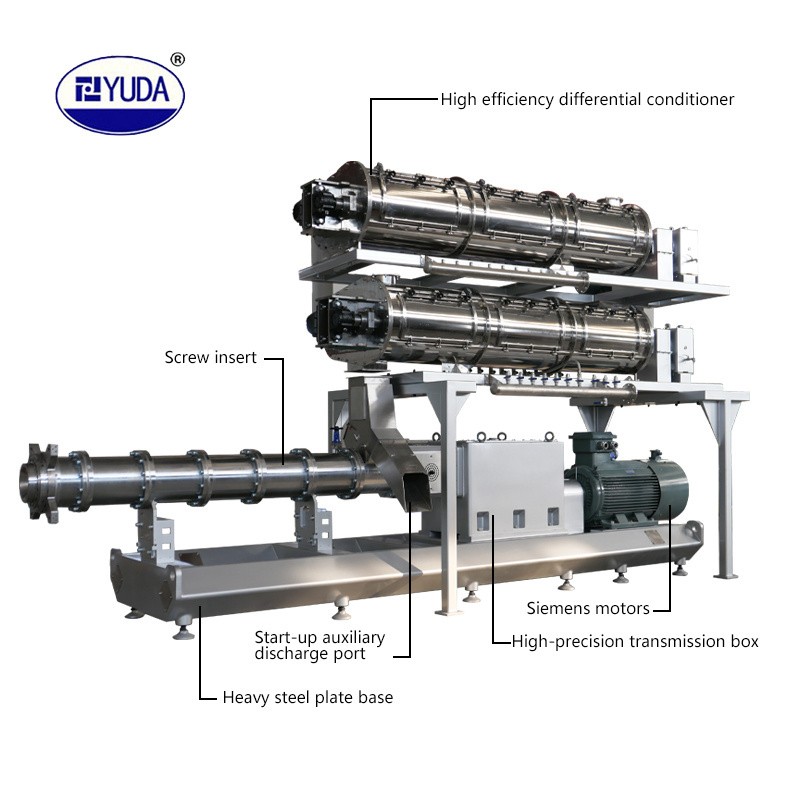

Twin-screw wet puffers are commonly used for the production of puffed feed. The material is sent to the temperer by the conveying equipment, the material is tempered by high temperature steam in the temperer, and enters the puffing mechanism by the lagoon, which is pumped by a pair of parallel meshed screws and cut into pellets by instant extrusion from a certain shape of the die

hole. The expansion of the material condition is influenced by more factors, but mainly with the tempering conditions, the operating conditions of the puffing machine and material properties are closely related. Changing the extrusion conditions cancontrol the sinkability of the puffed feed.

Production process for

10-15 ton/h Custom Design Automatic Dog Cat Fish Pet Food Making Machine Processing Extruder Production Line

:

The details for the line are as below: Pet food machine technology:

Receiving hopper→Auto batching system → Groase mixing system → grinding system → Fine mixing system →Conditioning & Extruder/puffing system→Drying system→Flavoring& oil spraying system→Cooling machine→Grease adding machine→packaging system

Receiving hopper→Auto batching system → Groase mixing system → grinding system → Fine mixing system →Conditioning & Extruder/puffing system→Drying system→Flavoring& oil spraying system→Cooling machine→Grease adding machine→packaging system

|

Model

|

Main power

|

cutter power

|

Conditioner power

|

capacity

|

|

YGT108

|

110/200

|

4

|

11*2

|

2-3t/h

|

|

YGT138

|

200/315

|

5.5

|

18.5*2

|

4-7t/h

|

|

YGT158

|

355/500

|

7.5

|

22*2

|

8-15t/h

|

|

YGT178

|

500/630

|

11/15

|

37*2

|

15-20t/h

|

Successful Project Showcase

Iran Expansion Project

Cooler

A

dvanced counter-current cooling principle,suitable for various forms of feed cooling:pellets,expansion materials,extruded materials,tableting materials,etc.

E

quipped with power:1.5KW-3KW;

C

apacity:2T/H-30T/H;

G

reatly reduce the crushing rate and remove the dead corners of cooling.

Double-barrel sieve

T

he container-style large-open door design is novel and unique;

T

he outlet of the finished product is reserved with a suction port,which can remove light impurities after connecting with the wind net, and has a strong comprehensive performance;

T

he sieve drum can be disassembled, saving cost and convenient maintenance;

F

ixed and mobile options, wide application;

O

ptional cylinder injection function to increase the efficiency of impurity removal.

Shredder

W

idely used in the crushing of livestock and poultry pellets and aquatic pellets;

O

utput:2T/H-30T/H;

E

quipped with power:4KW

22+1.5KW;

F

ast and slow double rollers realize particle crushing based on the principle of differential speed,with high yield and less grading return;

A

ccording to different crushing granularity requirements,a crushing roller a special tooth profile can be configured ;

Grading screen

S

elf-balanced vibration,good screening effect,small size, stable operation;

O

utput:5T/H-30T/H;

E

quipped with power:0.25*2 KW/0.55*2 KW;

S

treamlined design of the discharge port,no material deposition.

Grinder

E

quipped with power:37KW-315KW;

U

sing the northeast dried corn as raw material,moisture content≤13%;

O

utput:3.0-45.0T/H;

E

quipped with power:1.1KW-2.2KW;

M

agnetic field of iron separator≥3500GS.

Mixer

E

quipped with power:3KW-110KW

E

ffective volume:0.2-20 cube meters

M

ixde capacity:0.1T/B-10T/B

C

oefficient of variation of mixing uniformity CV≤5%

Hot Searches