- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

DEPUMP

-

Model Number:

-

MAH

-

Place of Origin:

-

Hebei, China

-

Horsepower:

-

as customer request

-

Power Source:

-

Electric,Diesel

-

Cable Length:

-

as customer request

-

Outlet Size:

-

1inch-18inch,as customer request

-

Power:

-

as customer request

-

motor:

-

as customer request

-

Sealing:

-

Mechanical seal, packing seal, auxiliary impeller seal

-

MOQ:

-

1 Set

-

Theory:

-

Centrifugal Pump

-

Standard or Nonstandard:

-

Standard

-

Material:

-

A05,Cr27,Stainless steel, Cast iron

-

Efficiency:

-

Up to 88%

-

Connection Type:

-

flange

-

Lubrication:

-

Oil or Grease

-

Bearing:

-

Timken/FAG

-

Usage:

-

Mine dewatering/slag removal/Cement Plants

Quick Details

-

Application:

-

Mining industry, Dredging Sand, Dredging Slurry

-

Pressure:

-

High Pressure,as customer request

-

Voltage:

-

as customer request

-

Warranty:

-

1 year

-

Brand Name:

-

DEPUMP

-

Model Number:

-

MAH

-

Place of Origin:

-

Hebei, China

-

Horsepower:

-

as customer request

-

Power Source:

-

Electric,Diesel

-

Cable Length:

-

as customer request

-

Outlet Size:

-

1inch-18inch,as customer request

-

Power:

-

as customer request

-

motor:

-

as customer request

-

Sealing:

-

Mechanical seal, packing seal, auxiliary impeller seal

-

MOQ:

-

1 Set

-

Theory:

-

Centrifugal Pump

-

Standard or Nonstandard:

-

Standard

-

Material:

-

A05,Cr27,Stainless steel, Cast iron

-

Efficiency:

-

Up to 88%

-

Connection Type:

-

flange

-

Lubrication:

-

Oil or Grease

-

Bearing:

-

Timken/FAG

-

Usage:

-

Mine dewatering/slag removal/Cement Plants

Products Description

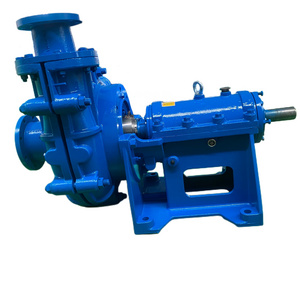

MAH Horizontal Slurry Pump

The

Depump®

slurry pump is the world’s standard for the most difficult mill duties. A wide variety of

impellers and shaft seals provide a perfect fit for a wide range of applications. The Depump® slurry pump provides excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost.

impellers and shaft seals provide a perfect fit for a wide range of applications. The Depump® slurry pump provides excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost.

Slurry Pump High Chrome (Cr27%) Material

CRz Driven Slurry Pump, for Mining use, solids dredging

MZJ Slurry Pump, for power plant, Aluminum plant, etc.

Material: High chrome(Cr27%), Rubber lined, Ceramic, Polyurethane

Details Images

Shaft

High-strength and wear-resistant material,long service life

High Toughness Screw

Ensure safe use

Surface galvanizing,anti rust and anti-corrosion

Reducer

The inlet and outlet dimensions of the water pump can be adjusted according to the on-site pipeline

Bracket

Strong heavy-duty bracket with little vibration

Features

· Bearing assembly

-

large diameter shaft with short overhang contributes to long bearing life.

· Liners – easily replaceable liners are bolted, not glued to the casing for positive maintenance.

· Casing – Casing halves of cast or ductile iron provide high operating pressure capabilities.

· Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination.

· Throatbush – wear is reduced and maintenance simplified by the use of tapered.

· Liners – easily replaceable liners are bolted, not glued to the casing for positive maintenance.

· Casing – Casing halves of cast or ductile iron provide high operating pressure capabilities.

· Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination.

· Throatbush – wear is reduced and maintenance simplified by the use of tapered.

Product Paramenters

|

Performance Of DP-MAH

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|||||||

|

Type

|

Max.

power

|

Capacity

|

|

Head

|

Impeller

|

|

Max.

particle

size

|

|||||||

|

|

|

|

|

|

Quantity

of vanes |

|

|

|||||||

|

|

kw

|

(m³/h)

|

|

(m)

|

(mm)

|

|

|

|||||||

|

1.5x1B-MAH

|

15

|

3.6-21.6

|

|

6-65

|

5

|

|

14

|

|||||||

|

1.5x2B-MAH

|

15

|

7.2-48.6

|

|

5-62

|

5

|

|

19

|

|||||||

|

2x3C-MAH

|

30

|

21.6-88.56

|

|

15-40

|

5

|

|

21

|

|||||||

|

4x3C-MAH

|

30

|

28.8-158.4

|

|

7-53

|

5

|

|

28

|

|||||||

|

6x4D-MAH

|

60

|

72-331.2

|

|

11-64

|

5

|

|

44

|

|||||||

|

8x6E-MAH

|

120

|

126-720

|

|

6-62

|

5

|

|

63

|

|||||||

|

10x8ST-MAH

|

560

|

216-1051.2

|

|

9-64

|

5

|

|

76

|

|||||||

|

12x10ST-MAH

|

560

|

316.8-1620

|

|

10-66

|

5

|

|

86

|

|||||||

|

14x12ST-MAH

|

560

|

504-2455.2

|

|

10-75

|

5

|

|

90

|

|||||||

Hot Searches