Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

SF19

-

Brand Name:

-

XF

-

Material:

-

Aluminum Alloy

-

MOQ:

-

10

-

Surface treatment:

-

Plating, Brushing, Polishing, Anodizing, Sandblasting, Knurling,

-

Drawing Format:

-

3D/CAD/DWG//STEP/PDF/ DXF

-

Tolerance:

-

±0.01mm~±0.05mm

-

Certificate:

-

ISO 9001

-

Roughness:

-

Ra0.2-Ra3.2(Custom Available)

-

Service:

-

One-Stop Service/OEM/ODM cnc machining parts service

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

SF19

-

Brand Name:

-

XF

-

Material:

-

Aluminum Alloy

-

MOQ:

-

10

-

Surface treatment:

-

Plating, Brushing, Polishing, Anodizing, Sandblasting, Knurling,

-

Drawing Format:

-

3D/CAD/DWG//STEP/PDF/ DXF

-

Tolerance:

-

±0.01mm~±0.05mm

-

Certificate:

-

ISO 9001

-

Roughness:

-

Ra0.2-Ra3.2(Custom Available)

-

Service:

-

One-Stop Service/OEM/ODM cnc machining parts service

Specification

|

Materials

|

Stainless Steel Carbon Steel Aluminum, Titannium alloys, Zinc alloy, Brass, Copper

|

|

Surface treatment

|

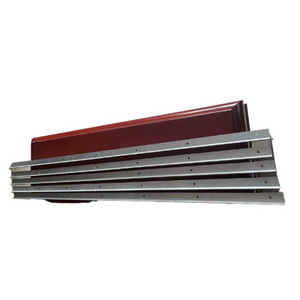

Wet Paint, Hard Anodized,Powder Coated, Painting, Polishing, Silk Screen, Plating, Blasting, Zinc/Nickel/Chrome/Titanium Plating

|

|

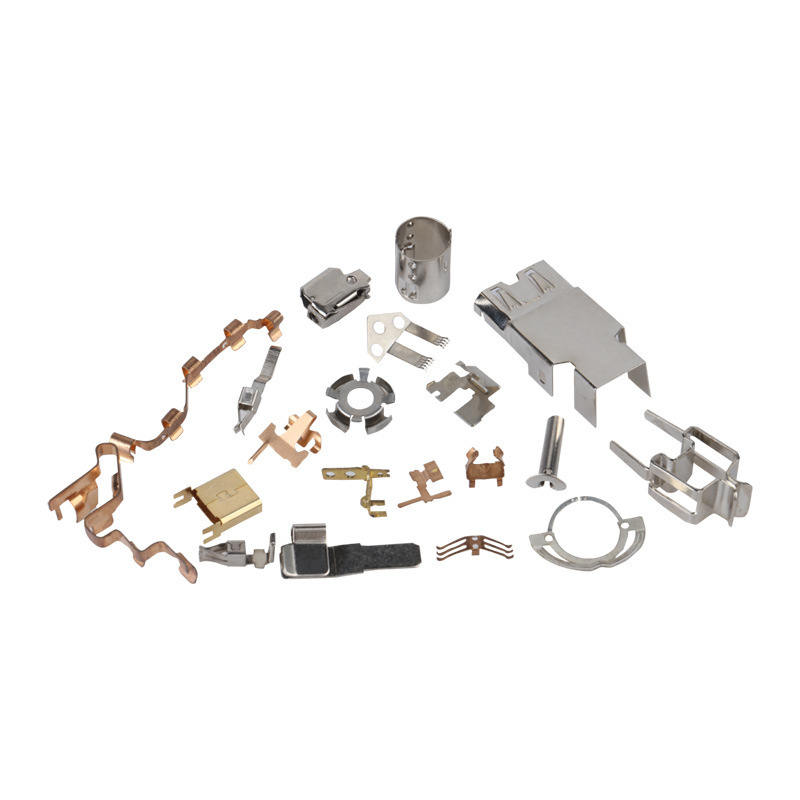

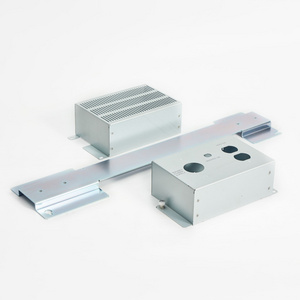

Processing

|

CNC turning, CNC milling, Drilling, Grinding, Spinning, Wire-EDM Cutting, Stamping, Laser Cutting, Bending, Metal processing, sheet metal processing, custom metal processing, machine parts, precision metal processing, CNC processing sheet

|

|

Precision

|

0.01mm-0.005mm

|

|

Tolerance丨Surface Roughness

|

+/-0.005 - 0.01mm 丨 Ra0.2 - Ra3.2(Custonize avaiable)

|

|

MOQ

|

1-10-50-100-200-1000-10000Pcs, depends on design

|

|

Drawing Format

|

3D/CAD/DWG//STEP/PDF/ DXF

|

|

Service

|

One stop service. Machining-assembly

|

|

Colors

|

black/blue/dark grey/orange/red

|

|

Lead time

|

Sample 3-5 business days, bulk production 15-20 business days

|

Why choose us?

★

With 10years of experience OEM ODM Services

★ ISO 9001 certified, AS 9100 &ISO 13485 compliant

★ Professional suggestions when in need

★ Tolerances down to ±0.0004″ (0.01mm)

★ Quality guaranteed. lf a part is not made to spec, we'll make it right.

★ Professional suggestions when in need

★ Tolerances down to ±0.0004″ (0.01mm)

★ Quality guaranteed. lf a part is not made to spec, we'll make it right.

Advanced Equipments

Three-dimensional testing equipment.

Bending Machine

CNC Precision Machining

Sheet Metal Stamping Machine

CNC Milling Machine

Various Materials

Stainless Steel

: 303, 304, 304L, 316, 316L, 410, 420, 430, etc.

This strong and durable metal has excellent corrosion resistance, making it ideal for products that may be exposed to harsh environments. Stainless steel is commonly used in the production of products such as kitchen utensils, medical equipment and automotive parts.

Strass:

HPb63, HPb62, HPb61, HPb59, H59,H68, H80, H90, etc.

It has a yellow appearance, hard texture, strong corrosion resistance. Widely used in making various instruments such as horns, trumpets, and trombones. In addition, brass can also be used to make industrial products such as clock parts, electrical contacts, door handles, etc.

Aluminum alloy:

AL6061, AL6063, AL6082, AL7075, AL5052, A380, etc

One of the most popular materials for CNC machining consumer products is aluminum. This lightweight metal has an excellent strength-to-weight ratio, good corrosion resistance, and can be easily machined into complex shapes. Commonly used in the production of products such as smartphone casings, computer parts and consumer electronics

Plastic:

ABS, PC, PP, PE, POM, Delrin, Nylon, Teflon, PEEK, PEI, etc

A common material used for CNC machining consumer products. There are a wide variety of plastics available, each with its own unique properties and benefits. For example, ABS , is a durable plastic commonly used in toys, electronics casings, and automotive parts. Polycarbonate is another popular plastic with excellent impact resistance and is often used to produce safety glasses, medical equipment and electronics casings.

Surface Treatment

Polishing

Hard Anodized

Oxidation

Electropolishing

Paint

Laser Engraving

Powder Coating

Bead Blasting

Passivation

Tolerances

|

Linear dimensional tolerance without separate tolerance according to ISO2768 ( Millimeters)

|

|

|

|

|

||||

|

Baic Size Range

|

Fine

|

Medium

|

Coarse

|

Very Coarse

|

||||

|

0.5 up to 3

|

0.05

|

±0.1

|

±0.2

|

➖

|

||||

|

Over 3 up to 6

|

±0.05

|

±0.1

|

±0.3

|

±0.5

|

||||

|

Over 6 up to 30

|

±0.1

|

±0.2

|

±0.5

|

±1

|

||||

|

Over 30 up to 120

|

±0.15

|

±0.3

|

±0.8

|

±1.5

|

||||

|

Over 120 up to 400

|

±0.2

|

±0.5

|

±1.2

|

±2.5

|

||||

|

Over 400 up to 1000

|

±0.3

|

±0.5

|

±2

|

±4

|

||||

|

Over 1000 up to 2000

|

±0.5

|

±1.2

|

±3

|

±6

|

||||

|

Over 2000 up to 4000

|

➖

|

±2

|

±4

|

±8

|

||||

Hot Searches