- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Operate easily

-

Product name:

-

Small Corn Maize Self-priming Grain Grinder Machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

songbai

-

Weight:

-

80 KG

-

Marketing Type:

-

Operate easily

-

Product name:

-

Small Corn Maize Self-priming Grain Grinder Machine

Corn Bean Grain Mill Grinder/Maize Milling Machine Self-Priming Flour Mill Soybean Disk Hammer Mill Crushing Feed Grinder

Products Description

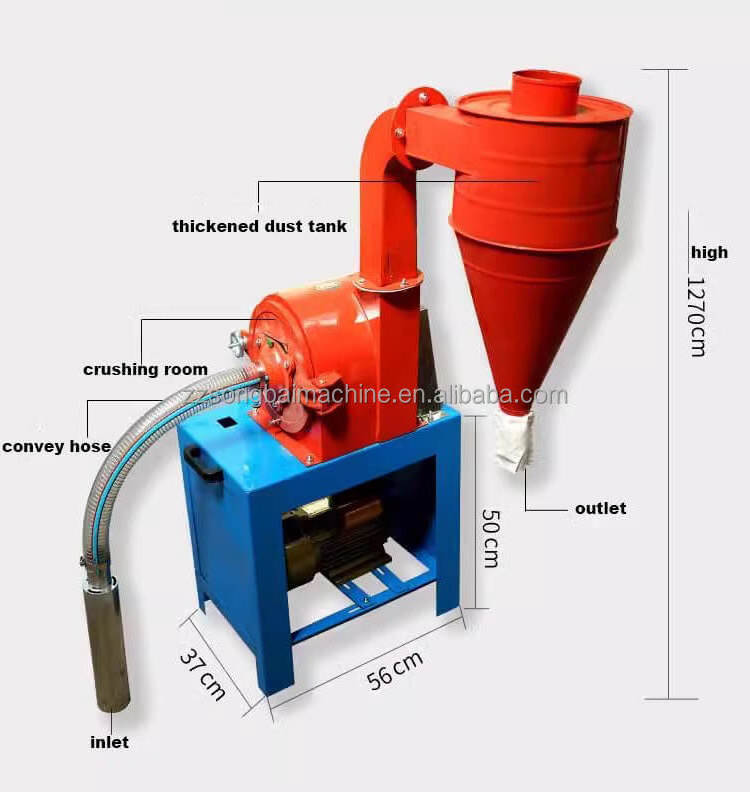

Introduction of Maize Milling Machine Self-Priming Flour Mill

This

Corn Bean Grain Mill Grinder

is mainly used for grinding wheat, rice, corn, sorghum, beans and etc. to be flour as your required sizes. it is very suitable and best choice for home using and small farm, especially for making wheat/ rice/ corn/ sorghum/beans into fine powder to be as the animal feed.

This is excluding the price of the motor. We still have many other models. If you need, you can contact us. Thank you!

Technical Parameters

|

Product name

|

self priming corn grinding

|

|

Rated voltage

|

220V

|

|

Power

|

4kw

|

|

Output

|

500-600kg/h

|

|

Machine size

|

1270*560*370mm

|

|

Weight

|

80kg

|

|

Application

|

corn, soybeans, coffee beans, etc.

|

Machine advantage

Features of

Self-priming Grain Grinder

:

1. The design of self-suction function can save more labor;

2. The tooth claw type makes it more durable, and it is more suitable for small size grain, such as rice, wheat, corn, beans and so on;

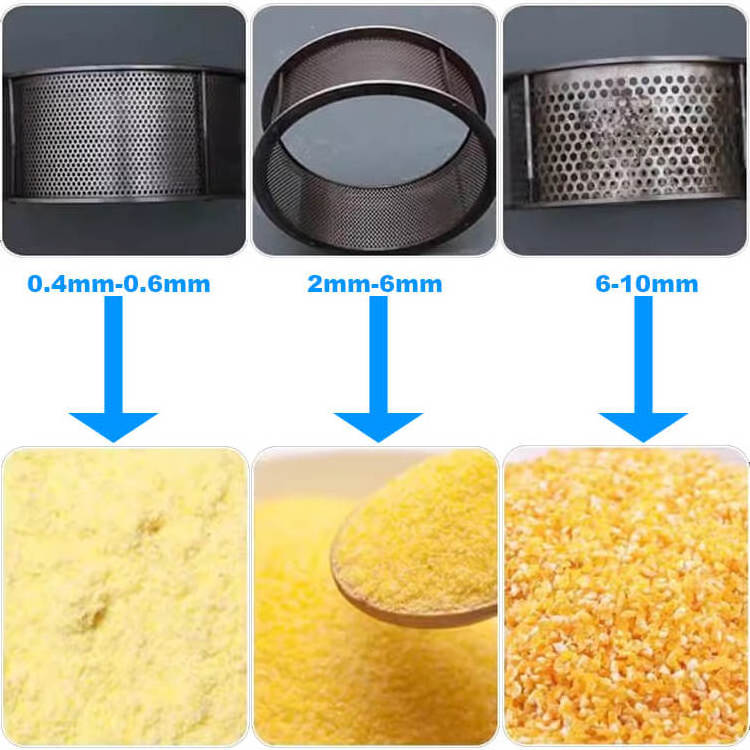

3. Customized screen can control the size of finished products as you required;

4. We could supply this machine with diesel engine instead of electric motor if the electric power is unavailable;

Working Principles

The

Maize Self-priming Grinder

is composed of a crushing chamber, a motor, a fan, a cyclone separator, and a base. This animal feed crushing machine uses the relative movement of the fixed teeth and the movable teeth to quickly grind the materials. When the movable tooth disc rotates at a high speed, The strong airflow drives the materials in the crushing chamber to fall from the screen into the fan, and driven by the fan, it flows out through dust removal. According to the needs of materials, different specifications of sieves can be selected, which can process materials of different thicknesses.

Factory Real Shot

Product Application

Customer Case

Hot Searches