- Product Details

- {{item.text}}

Quick Details

-

Application:

-

traction locomotive

-

Material:

-

Electro Graphite

-

Size:

-

2(7.5*50*57)mm

Quick Details

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

sn industry

-

Model Number:

-

L93MF7

-

Application:

-

traction locomotive

-

Material:

-

Electro Graphite

-

Size:

-

2(7.5*50*57)mm

PRODUCTS DESCRIPTION

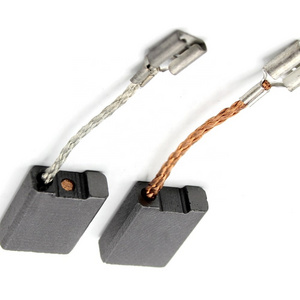

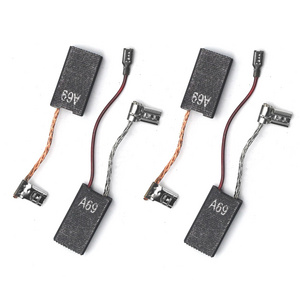

Bosc GWS14-150CI electric breaker and angle grinder carbon brush E64 with size 6 * 16 * 26mm

The epoxy resin-bonded materials of these carbon brushes are characterized in particular by great vibration damping properties.For this reason, they are primarily used in high-speed or commutator peripheral-speed motors. The sliding properties are already good and can be improved with impregnation. The resistance range of 100 to 1,500 µΩm (up to 10,000 µΩm as required) enables these materials to be used in motors of all performance classes.- vacuum clear This pitch-bonded graphite material-based carbon brush, which features a resistance range of 35 to 3,000 μΩm, opens up a broad spectrum of uses for motors of all performance classes. The carbon brush is separated in the center by an electrically insulating layer which makes it especially low wearing and thus the first choice for highly stressed motors in washing machines. The optional running-surface coating reduces the break-in time and noise emissions and may also prevent additional roughening of the commutator.

>Copper graphite:

J102, J105, C42, C412, J164, J201, H0505, H0507, H71, J203, J204, J205, J206,

J210, J213, J215, J230, J239, J240, J412, J453, CM5B, CM8100

>Silver and graphite:

J390-1, J390, J385, J385, J380, J375, J370, J360, J350, J325

>Electrochemical graphite:

D104, D172, D172NM, D213, D214, D252, D308, D308L, D312, D374B, D374L,

D374F, D374N, D374S, D376, D376N, D376Y, CH17, CH33N

>Resin graphite:

S4, S31, R015, R211

>Natural graphite:

S3, S6, S6M, S27, S28, NCC63

>Copper graphite:

J102, J105, C42, C412, J164, J201, H0505, H0507, H71, J203, J204, J205, J206,

J210, J213, J215, J230, J239, J240, J412, J453, CM5B, CM8100

>Silver and graphite:

J390-1, J390, J385, J385, J380, J375, J370, J360, J350, J325

>Electrochemical graphite:

D104, D172, D172NM, D213, D214, D252, D308, D308L, D312, D374B, D374L,

D374F, D374N, D374S, D376, D376N, D376Y, CH17, CH33N

>Resin graphite:

S4, S31, R015, R211

>Natural graphite:

S3, S6, S6M, S27, S28, NCC63

PRODUCT SPECIFICATIONS

|

Applicable mechanical models

|

|

|

|

|

||||

|

GBH5-38D

|

GBH5-38X

|

GBH5-40D

|

TSH5000

|

TSH5000PLUS

|

||||

|

GSH5

|

GSH388

|

GSH388X

|

|

|

||||

|

GWS7-100

|

GWS7-100T

|

GWS7-100E

|

GWS7-125

|

GWS7-125E

|

||||

|

GWS750-100

|

GWS750--125

|

GWS720

|

|

|

||||

|

No

|

Item

|

Data

|

|

|

|

1

|

Material

|

Electric graphite

|

|

|

|

2

|

size

|

6.3*12.5*23mm

|

6*16*26mm

|

|

|

3

|

Density

|

1.68

|

|

|

|

4

|

Resistivity

|

51

|

|

|

|

5

|

Shore hardness

|

50

|

|

|

|

6

|

Coef

|

0.22

|

|

|

|

7

|

Current density

|

12.5

|

|

|

|

8

|

Contact voltage drop

|

1.7

|

|

|

PRODUCTS DETAILS

Application and size

Small grinder, electric grinding head ,size :5*5*13mm

Application and size

100 type cutting machine, electric hammer, Size:5*8*15mm

Application and size

Electric circular saw, 38 electric hammer, aluminum sawing machine ,Size :7*13*17mm

Application and size

355 cutting machine, electric pickaxe ,size:7*17*18mm

Application and size

Sanding machine, electric grinder,size:5*8*12mm

Application and size

125 angle grinder,size:5*10*15mm

Application and size

255 aluminum sawing machine ,size:7*11*17mm

Application and size

Curve saw, electric drill,size:6*9*12mm

Application and size

Makita angle grinder ,size:5*11*16mm

SIMILAR PRODUCTS

Material

The quality of carbon brush material determines their effectiveness

Copper wire

Bold pure copper wire with stronger current load capacity

Insulation

High temperature resistant sleeve for stronger safety

Terminal

Soldered copper joints for greater stability

Packing

Use appropriate packaging according to customer needs

carbon brush type 1

There are some Single wafer with multiple shunts types for reference,view more pls contact us .

carbon brush type 2

There are some Multiple waferes with one shunt per wafer types for reference,view more pls contact us .

carbon brush type 3

There are some Multiple waferes with mulfiple shunts per wafer types for reference,view more pls contact us .

PRODUCTION

PRODUCT PACKAGING

packing details

Carton packaging

Pallet packaging

Wooden box packaging

Successful Project

Project in Thailand

Project in India

Project in Russia

FAQ

How to select brushes for motors?

1-Identification and nameplate information

eg, Motor, Generator, Slip ring

eg,model , serial

eg,HP/KW, RPM, Volts,Amps

2-Describe the application

Eg, commutator Diameter

Eg, Slip ring is Synchronous , Steel ring, Wound Rotor, Bronze ring

Eg, General Industrrial , Steel Mill, Papermill , Elevator, Mining, Power Gen or other

3-Describe the brush

eg, From front side, botttom end, top bevel, bot bevel,

eg, the thickness, width, length

eg, solid, plytek or triply

4-Describe the shunt

eg, shunt locations, shunt lengnth

eg, tamed, rivet, insulated, measuring length

5-Describe the brush top

eg, pad, clip convex , channel

6-Describe the termial

eg, tube, crimped, flg, yoke, button, eared

Summary of Frequently Asked Questions?

1. Carbon brush wear Due to carbon brushes being a friction material, long-term use may inevitably lead to wear and tear. Whenthe carbon brush wears to a certain extent, its working efficiency will significantly decrease, and even cannot function properly. At this time, carbon brushes should be replaced in a timely manner to ensure the normal operation of the equipment.

2. Poor contact of carbon brushes Carbon brushes generally come into contact with the motor rotor through elastic carbon brush blades. If the carbon brush blades age or have insufficient elasticity, it is easy to cause poor contact. In addition, dust and dirt can also affect the contact between the carbon brush blade and the rotor. At this point, you can gently wipe the surface of the carbon brush and motor rotor with fine sandpaper to remove surface oxides and loose dirt, and increase the contact area.

3. Carbon brush heating Some tools may experience the problem of carbon brushes heating up during use. This is usually due to the small contact area between the carbon brush and the rotating parts, or the poor quality of the carbon brush material leading to an increase in resistance. If the carbon brush heats up during use, it should be stopped immediately, checked and replaced to avoid subsequent losses.

4. Carbon brush lifespan The service life of carbon brushes of different brands and specifications varies, but regardless of the type, regular inspection and timely replacement are required. If the equipment has not been used for a long time, it is best to remove and store the carbon brushes first to avoid aging and deformation.

1-Identification and nameplate information

eg, Motor, Generator, Slip ring

eg,model , serial

eg,HP/KW, RPM, Volts,Amps

2-Describe the application

Eg, commutator Diameter

Eg, Slip ring is Synchronous , Steel ring, Wound Rotor, Bronze ring

Eg, General Industrrial , Steel Mill, Papermill , Elevator, Mining, Power Gen or other

3-Describe the brush

eg, From front side, botttom end, top bevel, bot bevel,

eg, the thickness, width, length

eg, solid, plytek or triply

4-Describe the shunt

eg, shunt locations, shunt lengnth

eg, tamed, rivet, insulated, measuring length

5-Describe the brush top

eg, pad, clip convex , channel

6-Describe the termial

eg, tube, crimped, flg, yoke, button, eared

Summary of Frequently Asked Questions?

1. Carbon brush wear Due to carbon brushes being a friction material, long-term use may inevitably lead to wear and tear. Whenthe carbon brush wears to a certain extent, its working efficiency will significantly decrease, and even cannot function properly. At this time, carbon brushes should be replaced in a timely manner to ensure the normal operation of the equipment.

2. Poor contact of carbon brushes Carbon brushes generally come into contact with the motor rotor through elastic carbon brush blades. If the carbon brush blades age or have insufficient elasticity, it is easy to cause poor contact. In addition, dust and dirt can also affect the contact between the carbon brush blade and the rotor. At this point, you can gently wipe the surface of the carbon brush and motor rotor with fine sandpaper to remove surface oxides and loose dirt, and increase the contact area.

3. Carbon brush heating Some tools may experience the problem of carbon brushes heating up during use. This is usually due to the small contact area between the carbon brush and the rotating parts, or the poor quality of the carbon brush material leading to an increase in resistance. If the carbon brush heats up during use, it should be stopped immediately, checked and replaced to avoid subsequent losses.

4. Carbon brush lifespan The service life of carbon brushes of different brands and specifications varies, but regardless of the type, regular inspection and timely replacement are required. If the equipment has not been used for a long time, it is best to remove and store the carbon brushes first to avoid aging and deformation.

Hot Searches