Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

52 rpm

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

plastic extrusion line

-

Voltage:

-

380V50HZ

-

Dimension(L*W*H):

-

90*12*4.8M

-

Power (kW):

-

700

-

Weight:

-

180 KG

-

Product name:

-

PP Melt blown non woven fabric

-

Usage:

-

make face mask

-

Width:

-

100~300mm

-

Type:

-

Meltblown Filter Material

-

Packing:

-

film carton

-

Grade:

-

BFE99, PFE95+, PFE97+

-

MOQ:

-

500KGS

-

Roll length:

-

500Meters/roll

-

Certification:

-

en149

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

28:1

-

Screw diameter (mm):

-

150 mm

-

Screw Speed (rpm):

-

52 rpm

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

plastic extrusion line

-

Voltage:

-

380V50HZ

-

Dimension(L*W*H):

-

90*12*4.8M

-

Power (kW):

-

700

-

Weight:

-

180 KG

-

Product name:

-

PP Melt blown non woven fabric

-

Usage:

-

make face mask

-

Width:

-

100~300mm

-

Type:

-

Meltblown Filter Material

-

Packing:

-

film carton

-

Grade:

-

BFE99, PFE95+, PFE97+

-

MOQ:

-

500KGS

-

Roll length:

-

500Meters/roll

-

Certification:

-

en149

-

Marketing Type:

-

Ordinary Product

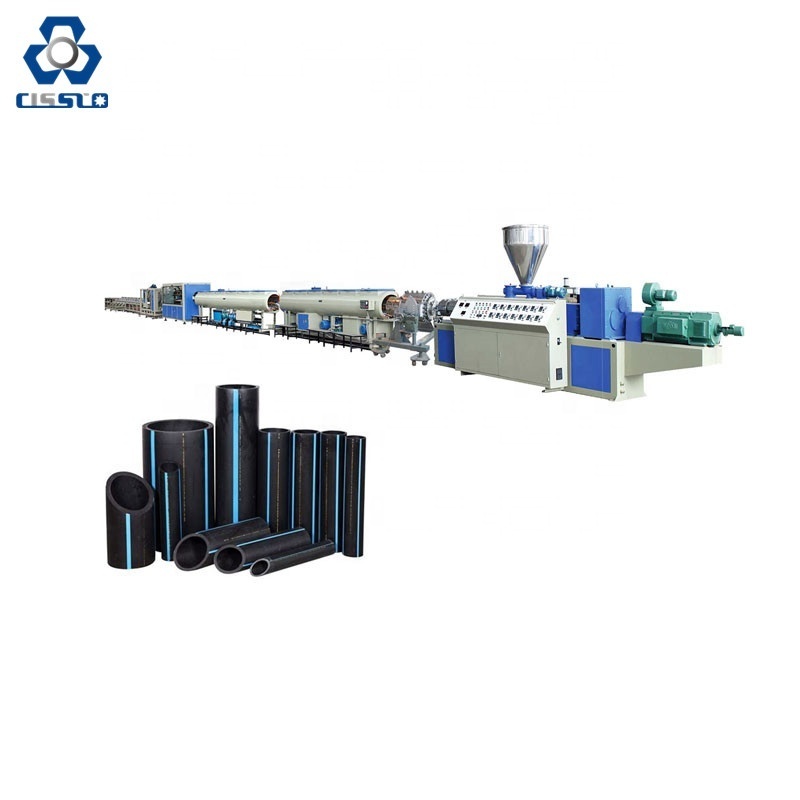

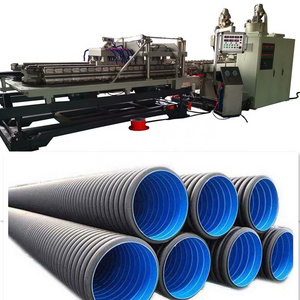

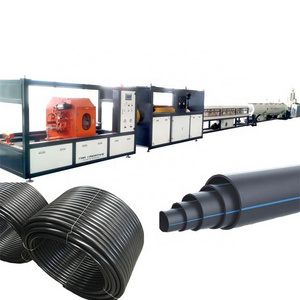

Product Introduction

SXG series precision tube extrusion line is the third generation (high speed) series precision pipe line which designed and made by CISSCO EXTRUSION, this line is mainly used for producing various kinds of small plastic pipe, such as PA/PU automobile tube, high pressure air and liquid transmission tube, medical catheter, multi-layer composite tube, clean containers straw, and precision communication cable etc. Main feature of this line: high productive efficiency, excellent dimensional stability and high automation degree.

This extrusion line has adopted the "accurate control of weak vacuum" and "high pressure volumetric extrusion" technology, which are initiated by our own team. It has reformed the shortage of traditional technology which can not balance extrusion speed and precision control, especially when it is applied in engineering plastics tubes. It can meet the high precision extrusion control and achieve ideal production efficiency as well. In this way, it can greatly improve the customer’s value-in-use of machine and bring remarkable cost-reduction effect for the customers

Specification

|

Raw material & formulation

|

PP resin, All the material should be mixed completely.

|

|

Melt capacity

|

350-400kg/h

|

|

Production Efficiency

|

4kg/Kw, Very high working efficiency

|

|

Central height

|

1000mm

|

|

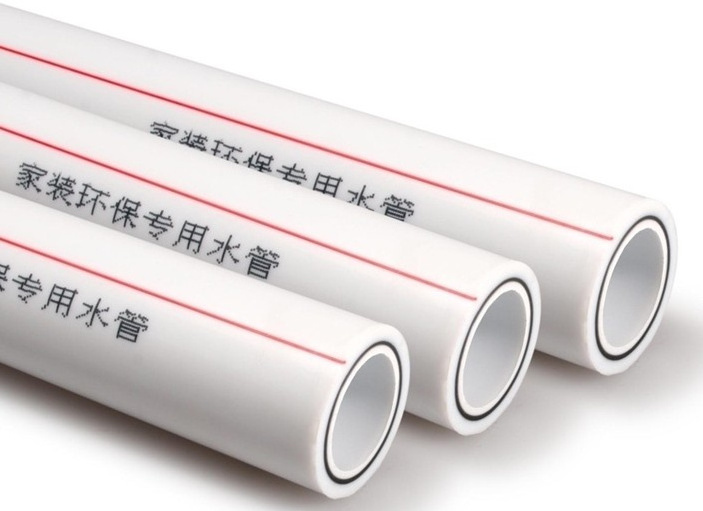

Quantity of color stripe

|

1line 2lines 4 lines

|

|

Max. extrusion speed

|

Max: HDPE ≥25m/min

|

|

|

PP-R≥15m/min

|

|

Operation direction

|

From right to left (face to the operation panel)

|

|

Machine color

|

Standard color: RAL7016 (Anthracite grey)

|

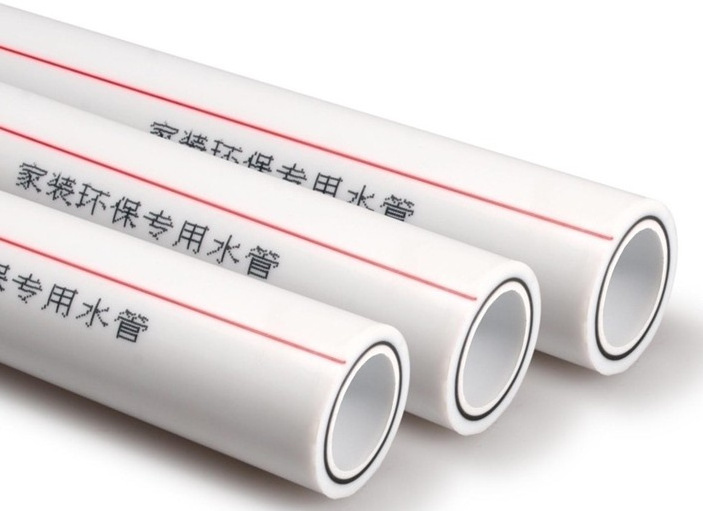

Pipe species and size list of fiberglass ppr pipe production line

|

No.

|

O.D. (mm)

|

Wall thickness (mm) 1

|

Wall thickness (mm) 2

|

Wall thickness (mm) 1

|

Wall thickness (mm) 2

|

|

1

|

16

|

SDR

|

SDR

|

SDR

|

SDR

|

|

2

|

20

|

SDR

|

SDR

|

SDR

|

SDR

|

|

3

|

25

|

SDR

|

SDR

|

SDR

|

SDR

|

|

4

|

32

|

SDR

|

SDR

|

SDR

|

SDR

|

|

5

|

40

|

SDR

|

SDR

|

SDR

|

SDR

|

|

6

|

50

|

SDR

|

SDR

|

SDR

|

SDR

|

|

7

|

63

|

SDR

|

SDR

|

SDR

|

SDR

|

Machine list of fiberglass ppr pipe production lin

e

|

No.

|

Name

|

Qty.

|

|

1

|

Vacuum loader 400kg/h

|

1set

|

|

2

|

Hopper dryer 400kg/h

|

1set

|

|

3

|

BRD60/38 Single Screw Extruder With PLC Controller

|

1set

|

|

4

|

SJ25/25 Color Stripe Co-extruder

|

1set

|

|

5

|

Die head

|

1set

|

|

6

|

Disk vacuum calibrator

|

7sets

|

|

7

|

BR-VT/63/2/9 Two Chambers Vacuum Calibration Tank

|

1set

|

|

8

|

BR-SB/63/9 Spray Cooling Tank

|

1set

|

|

9

|

BR-HC/63 Two-belt Haul-off

|

1set

|

|

10

|

BR-CF/63 Guillotine Cutter

|

1set

|

|

item

|

value

|

|

Application

|

net

|

|

Plastic Processed

|

PE, PP

|

|

Condition

|

New

|

|

Screw Design

|

Double-screw

|

|

|

Counter-rotating conical Twin-screw

|

|

Screw Material

|

38CrMoALA

|

|

Screw diameter (mm)

|

150 mm

|

|

Screw L/D Ratio

|

28:1

|

|

|

52rpm

|

|

Place of Origin

|

China

|

|

|

Shanghai

|

|

|

plastic extrusion line

|

|

|

380V50HZ

|

|

|

90*12*4.8M

|

|

|

700

|

|

|

180KG

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

High Productivity

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Construction works

|

|

Marketing Type

|

Ordinary Product

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Bearing, Motor, Gear, PLC, Engine, Gearbox, Screw

|

|

Product name

|

PP Melt blown non woven fabric

|

|

Usage

|

make face mask

|

|

Width

|

100~300mm

|

|

Type

|

Meltblown Filter Material

|

|

Packing

|

film carton

|

|

Grade

|

BFE99, PFE95+, PFE97+

|

|

MOQ

|

500KGS

|

|

Roll length

|

500Meters/roll

|

|

Certification

|

en149

|

Product Description

Packing & Delivery

standard packages by sea and air

Hot Searches