- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

15000

-

Weight (KG):

-

9950 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Welldone Technology

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

3 kW

-

After Warranty Service:

-

Spare parts

-

Service:

-

Video technical support

-

Way to Control:

-

Touch Screen / Remote / Button

-

Way of Unloading:

-

Manual. Pneumatic

Quick Details

-

Barrel Volume (L):

-

100

-

Max. Loading Volume (L):

-

15000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 42 r.p.m

-

Max. Loading Capacity:

-

15000

-

Weight (KG):

-

9950 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Welldone Technology

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

3 kW

-

After Warranty Service:

-

Spare parts

-

Service:

-

Video technical support

-

Way to Control:

-

Touch Screen / Remote / Button

-

Way of Unloading:

-

Manual. Pneumatic

Product Description

Specification

|

item

|

value

|

|

Mixer Type

|

Homogenizer

|

|

Barrel Volume (L)

|

100

|

|

Material Processed

|

Plastics, Chemicals, Food, Medicine, Feed

|

|

Max. Loading Volume (L)

|

15000L

|

|

Range of Spindle Speed(r.p.m)

|

1-40

|

|

Max. Loading Capacity

|

15000

|

|

Weight (KG)

|

9950KG

|

|

Material

|

SUS304, SUS316L

|

|

Condition

|

New

|

|

Place of Origin

|

China

|

|

|

Jiangsu

|

|

Brand Name

|

Welldone Technology

|

|

Voltage

|

Customized

|

|

Dimension(L*W*H)

|

Customized

|

|

Power (kW)

|

3kW

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

Automatic

|

|

Applicable Industries

|

Manufacturing Plant, Food & Beverage Factory, Farms, Construction works , Other

|

|

Showroom Location

|

None

|

|

Marketing Type

|

Ordinary Product

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

2 years

|

|

Core Components

|

Motor, PLC, Other, Engine

|

|

After Warranty Service

|

Spare parts

|

|

Service

|

Video technical support

|

|

Way to Control

|

Touch Screen / Remote / Button

|

|

Application

|

Granule

|

Description

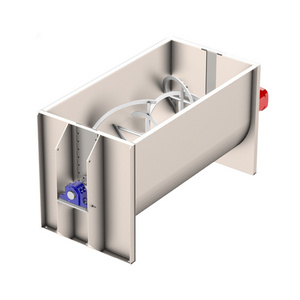

Ribbon Mixer consists of horizontal U shape mixing vessel, drive system and ribbon agitator. The mixing element is combined with inner and outer double helical ribbon agitator. The outer ribbon moves materials into center direction and inner ribbon moves the materials in opposition direction to shape radially and laterally movement. Finally,the material will be discharged at center discharge valve. Ribbon Blender is an efficient and versatile blending machine for mixing of dry granules powders homogeneously .Various materials can be mixed in ribbon mixer through a gentle way, especially in food material mixing. Furthermore, high speed chopper is also available to break some lumps during blending process.The cylinder cover can be made into arch or fully open. The arch can bear pressure. The fully open type is convenient to clean the interior of the equipment. The advantages of this machine are wide application range, high mixing uniformity, short mixing time and large loading coefficient.

Application

The horizontal spiral belt mixer is applicable to the mixing of powder and powder, particles and powder, powder and a small amount of liquid. It is widely used in chemical industry, medicine, food, feed, plastics, building materials and other industries. It can be made according to GMP standards. The machine has wide adaptability to mixtures, can mix viscous materials evenly, can keep particles as complete as possible for granular materials, and can better mix materials with a ratio difference of 1:1000 ~ 10000. The machine can also make heating, cooling, positive pressure, vacuum and other special forms according to the requirements of users.

Advantages

A. Driving advantage

The product adopts gear reducer direct drive, with large torque, high reliability and low noise. Large equipment adopts gear reducer and belt transmission, which can protect the transmission parts in case of accidents.

B. Flexible disassembly

The main shaft of the screw belt is connected with the flange of the drive shaft, which can be quickly removed when the mixing shaft type needs to be repaired or replaced. The flexible disassembly design makes the U-shaped cylinder completely welded with the plates at both ends to avoid the material accumulation gap caused by the large flange connection of the cylinder and reduce the residue.

C. Cylinder cover type

Compared with other types of mixers, the cylinder cover of horizontal spiral belt is more flexible and can be made into fully open, semi open and fully closed. Fully open is suitable for occasions with high cleaning requirements. It is convenient and safe to use gas spring support.

D. Discharge form

The discharge form is generally pneumatic flap valve. The arc valve is closely embedded in the cylinder and flush with the inner wall of the cylinder. There is no material accumulation and mixing dead angle. The reliable edge seal ensures no leakage in frequent switches.

E. Cooling and heating

A jacket can be added outside the mixer barrel to cool or heat the materials by injecting cold and hot medium into the jacket; Generally, industrial water is pumped for cooling, and steam or electric heating heat transfer oil can be introduced for heating.

F. Spindle seal

The new balanced combined air tight seal and packing seal are used. When mixing ultra-fine powder, this sealing form can increase the air tightness and effectively block the flow of air powder inside and outside the cylinder.

Hot Searches