- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HONGJI

-

Name:

-

Leaching Tank

-

Usage:

-

Leaching Equipment

-

Capacity:

-

50-2000t/d

-

Function:

-

Gold Extraction

-

Installation:

-

Engineer Guide

-

Price:

-

Negotiable

-

COLOR:

-

Customized

-

Material:

-

Carbon Steel

-

Delivery Time:

-

15-30 Days

Quick Details

-

Weight (KG):

-

3000

-

Application:

-

mining, Ore

-

Production Capacity:

-

customized

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HONGJI

-

Name:

-

Leaching Tank

-

Usage:

-

Leaching Equipment

-

Capacity:

-

50-2000t/d

-

Function:

-

Gold Extraction

-

Installation:

-

Engineer Guide

-

Price:

-

Negotiable

-

COLOR:

-

Customized

-

Material:

-

Carbon Steel

-

Delivery Time:

-

15-30 Days

Product Description

Product Description

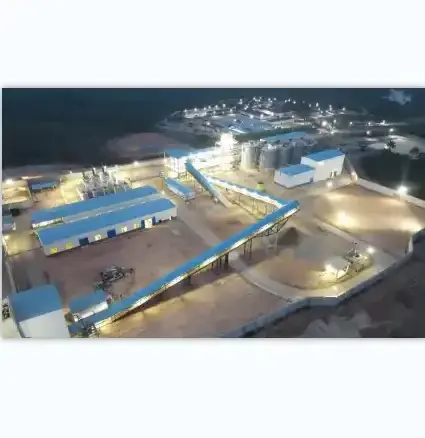

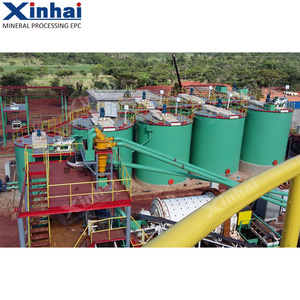

The leaching tank is an important equipment for leaching. The volume of the leaching tank is generally 50-100m². At present, it tends to be large Large-scale tanks of 120~400m²have been used in industry. The leaching tank is divided into a mechanical stirring tank and an air stirring tank. The mechanical stirring tank uses the power to drive the propeller to stir the pulp, and the air stirring tank uses the compressed air to stir the pulp.

Work Principle

Working principle

When the double impeller leaching mixing tank is working, the pulp will flow from the top to the bottom under the drag and stirring action of the double impeller, diffuse through the surrounding damping plate, and feed air at the lower end of the shaft to mix with the pulp Circulate upward to form a uniform suspension mixture.

Product Features

Features:

Ventilation, is surrounded by air to the bottom of the tube or hollow shaft ventilation, make the air through the air tube or hollow shaft into the mixing tank, uniform gas dispersion, small air bubbles.

The is a new type of rubber impeller in large diameter, rotational speed is low, long service life.

Have very strict control on the stirring intensity, make the concentration of the mixing tank and fineness is consistent with the

distribution. To improve the rate of pass in and out of cyanide and carbon adsorption rate.

The is a new type of rubber impeller in large diameter, rotational speed is low, long service life.

Have very strict control on the stirring intensity, make the concentration of the mixing tank and fineness is consistent with the

distribution. To improve the rate of pass in and out of cyanide and carbon adsorption rate.

Specification

Hot Searches