- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0

-

CrO Content (%):

-

0

-

SiC Content (%):

-

0

-

Place of Origin:

-

China

-

Model Number:

-

AZS41

-

Brand Name:

-

Sunrise

-

ZrO2:

-

≥40.50

-

Bulk density(g/cm3):

-

≥4.00

-

Apparent Porosity %:

-

≤1.2

-

Cold Crushing Strength Mpa:

-

≥300

-

Exudation Temperature of Glass Phase:

-

≥1410

-

Bubble Separation Ratio:

-

≤1.0

-

Anti-corrosion rate of glass liquid:

-

≤1.2

-

Size:

-

any size

-

Name:

-

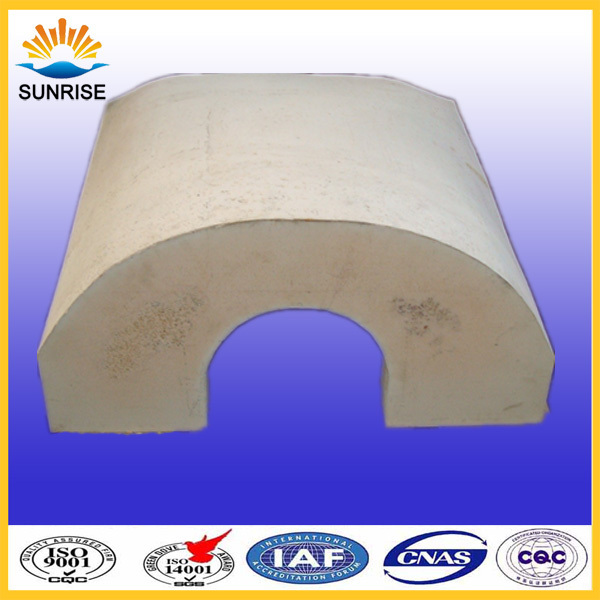

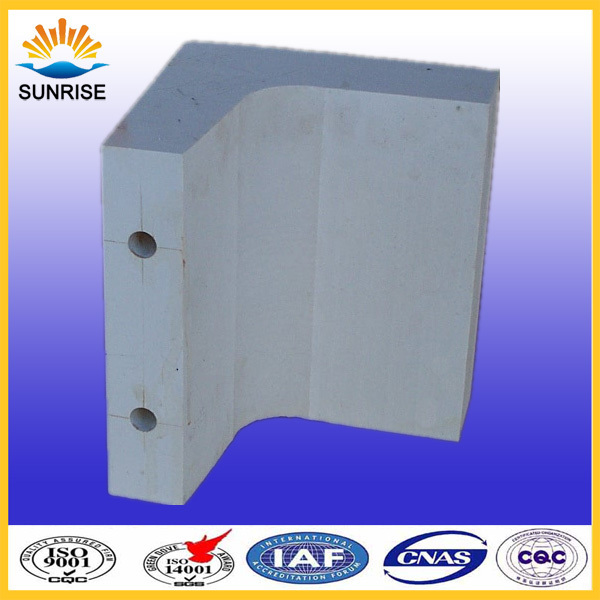

curved fire brick

-

Item:

-

curved fire brick

Quick Details

-

SiO2 Content (%):

-

≤13

-

Al2O3 Content (%):

-

≥45.00

-

MgO Content (%):

-

0

-

CaO Content (%):

-

0

-

CrO Content (%):

-

0

-

SiC Content (%):

-

0

-

Place of Origin:

-

China

-

Model Number:

-

AZS41

-

Brand Name:

-

Sunrise

-

ZrO2:

-

≥40.50

-

Bulk density(g/cm3):

-

≥4.00

-

Apparent Porosity %:

-

≤1.2

-

Cold Crushing Strength Mpa:

-

≥300

-

Exudation Temperature of Glass Phase:

-

≥1410

-

Bubble Separation Ratio:

-

≤1.0

-

Anti-corrosion rate of glass liquid:

-

≤1.2

-

Size:

-

any size

-

Name:

-

curved fire brick

-

Item:

-

curved fire brick

Fused cast azs refractory brick curved fire brick used for dam blocks

Specifications

Fused cast azs41 brick

1. Strong corrosion resistance to glass liquid

2. Used in glass liquid contact part

3.No pollution to glass

Product description

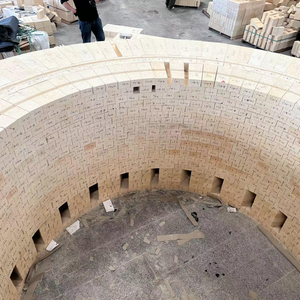

Fused Cast AZS bricks are the most widely used materials both in glass contact and superstructure of glass

melting furnaces. The products have passed the ISO international certified, are made of high pure

material, fired at high temperature by advanced technology, with the advantages of high strength, high

compression resistance, good thermal shock resistance, good performance in high temperature,

good thermal conductivity, good erosion resistance and so on. Widely be used for linings of furnace

in industries.

Features

1.Casted by melting raw material in the mold, then cooling and solidification.

2.Strong glass corrosion resistance and high thermal shock stability.

3.Good wear-resistance,slag-resistance and alkali corrosion resistance.

4.High-purity raw material, barely no pollution.

5.Top quality, long service time.

Applications

1.Sidewalls of flame furnaces with embedded melter bottoms.

2. This product is only available for straight brick.

Physical properties and chemical composition

|

Item |

Behaviors |

|||

|

TY-33 |

TY-36 |

TY-41 |

||

|

Chemical Composition |

Al 2 O 3 |

≥50.00 |

≥49.00 |

≥45.00 |

|

ZrO 2 |

≥32.50 |

≥35.50 |

≥40.50 |

|

|

SiO 2 |

≤15.50 |

≤13.50 |

≤13.00 |

|

|

Na 2 O+K 2 O |

≤1.30 |

≤1.35 |

≤1.30 |

|

|

Bulk density |

≥3.75 |

≥3.85 |

≥4.00 |

|

|

Apparent Porosity |

≤1.2 |

≤1.0 |

≤1.2 |

|

|

Cold Crushing Strength Mpa |

≥300 |

≥300 |

≥300 |

|

|

Exudation Temperature of Glass Phase |

≥1400 |

≥1400 |

≥1410 |

|

|

Bubble Separation Ratio |

≤1.2 |

≤1.0 |

≤1.0 |

|

|

Anti-corrosion rate of glass liquid (%) 1500°C×36h (mm/24h) |

≤1.5 |

≤1.4 |

≤1.2 |

|

|

Apparent density (g/cm3) |

PT(RN RC N) |

≥3.50 |

≥3.50 |

≥3.70 |

|

ZWS(RR EVF EC ENC) |

≥3.65 |

≥3.70 |

≥3.90 |

|

|

WS( RT VF EPIC FVP DCL) |

≥3.70 |

≥3.8 |

≥4.00 |

|

Trading Process

Cast Process

Zhengzhou Sunrise Refractory Co., Ltd. is mainly engaged in the production and development of refractory

materials for glass , petrochemistry, metallurgy, construction and nonerrous metal industries. Our main

products include fused cast AZS 33, 36,41, fused cast αβ alumina brick, crucibles, furnace fireclay bottom

block, silica, high alumina, magnesia, corundum, chrome, zircon, mullite, zirconia mullite, silicon carbide,

sillimanite, alumina bubble bricks, various insulation bricks, and ceramic fiber products,etc.

We sincerely welcome you to inquire for the products of Fire Brick Prices Fused Cast AZS TY-33# Refractories for Glass Furnace!

Why choose us?

Long history and various products:

Since 2005, Sunrise had engaged in the production of various fused cast AZS, such as fused cast AZS 1681, fused cast AZS ER 1685,fused cast AZS 1711, glass furnace fireclay bottom block, mullite brick, zircon brick, alumina bubble brick, sillimanite brick, corundum brick, low porosity fireclay brick, high alumina brick, all kinds of glass furnace ramming masses, sealing materials, building fireclay, etc.

So we have abundent experience on the design and production of refractory materials.

Abundent experience:

Sunrise can offer the customer excellent service relating to the production line of the float glass, which includes the design and advisory of the furnace and the tin bath, the matching of the materials and its construction. The products made by our company have been use in more than 80 production lines of float glass and production line of glass products both at home and abroad.

Our promise:

Sunrise conscientiously observes the government's line, policy, laws and regulations, follows the international trade practice, adheres to the principle of equality and mutual benefit, complies with contract and keeps the promise. BWTC upholds the principle of "combining industry with trade", "technology with trade" and "export with import", to serve its customers at home and abroad sincerely!

If you are interested in our products, please feel free to contact us! The best service will be offered!

Contact Us

Name: Yinyu Li

Factory Add: Xinmi City, Luoyang City

Tel: +86-371-63838939 Fax:+86-371-63835539

Mobile: +86-15565134635