Our tube fittings applications to connect, control, and direct the flow of fluids or gases through tubing systems. These fittings

provide a secure and leak-free connection, ensuring the efficient and reliable operation of fluid transfer systems. Tube fittings

come in a wide variety of types and styles, each designed for specific purposes. Some common types include compression fittings,

push-to-connect fittings, flare fittings, and quick-connect fittings. These fittings are typically made from high-quality

materials such as stainless steel, brass, or plastic, ensuring durability and resistance to corrosion. One of the primary

advantages of tube fittings is their versatility. They are compatible with a range of tubing materials, including metal, plastic,

and flexible hoses, allowing for use in different applications and industries. Tube fittings can be used in plumbing systems,

hydraulic and pneumatic systems, automotive applications, refrigeration systems, and more. Installation of tube fittings is

generally straightforward, requiring basic tools such as wrenches or spanners. Depending on the type, fittings may involve

compression rings, O-rings, or gripping mechanisms to create a tight and secure seal. It is crucial to follow proper installation

procedures and adhere to recommended torque levels to ensure optimal performance and prevent leakage. Safety is of utmost

importance when working with tube fittings. It is necessary to select fittings that are appropriate for the intended application,

considering factors such as pressure, temperature, compatibility with fluids or gases, and any specific industry standards or

regulations. Regular inspection and maintenance of tube fittings are recommended to identify and address any potential issues or

wear. In summary, our tube fittings play a critical role in fluid transfer systems by providing secure connections, controlling

fluid flow, and ensuring system efficiency. With their wide range of types and materials, they offer adaptability to diverse

applications across industries. Proper selection, installation, and maintenance of tube fittings are essential for the safe and

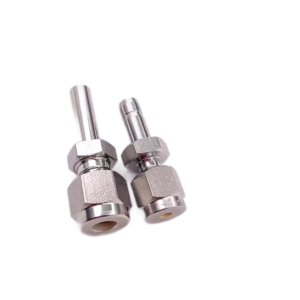

reliable operation of fluid systems.Two-Ferrule Tube Fitting is derived from Swagelok company, and this Fitting has these

Features:

1, Live-loaded, two-ferrule design.

2, Easy to install.

3, No torque is transmitted to tubing during installation.

4, Gap inspection gauge ensures sufficient pull-up upon initial installation.

Two-Ferrule, Mechanical Grip Design The two ferrules separate sealing and tube gripping functions; each ferrule is optimized for

its function.

The front ferrule creates a seal:

1, against the fitting body

2, on the tubing outside diameter.

As the nut is turned, the back ferrule:

1, axially advances the front ferrule

2, radially applies an effective tube grip.

Our product is completely interchangeable with Swagelok, and we maintain consistency with Swagelok in terms of raw materials,

machining, and post-treatment processes, thereby achieving the same product functionality and achieving complete

interchangeability