Address: No. 698 Wudu Road, Jiading District Shanghai, China.

Contact Phone No.: 0086-

13761380497

Contact Person: Crystal Chen

Website: www.root-asia.com

www.rootsandmill.com

- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2021

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Product name:

-

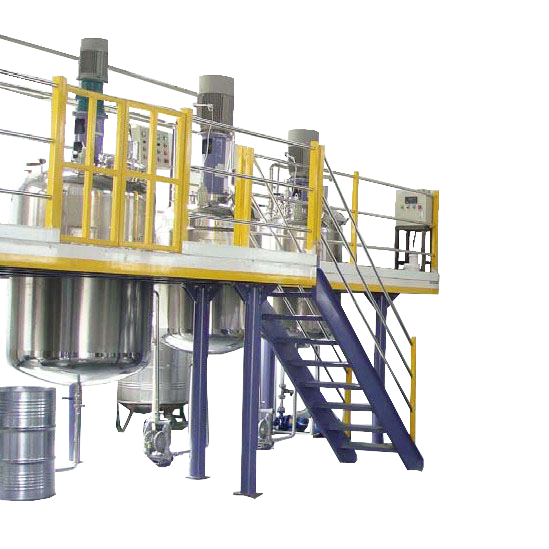

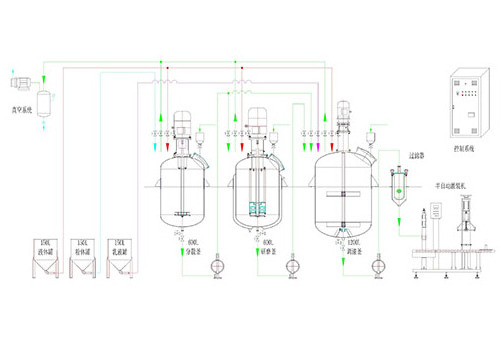

1000t Factory Exterior Emulsion Paint Production Line

-

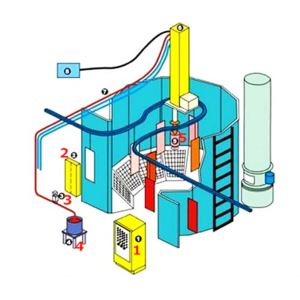

Dosing system:

-

latex feeding tank, vacuum buffer tank, vacuum pump

-

Dispersing system:

-

disperser, dispersering vessel

-

Milling system:

-

basket mill, grinding vessel

-

Tinting system:

-

paddle mixer, tinting vessel

-

Conveying filling:

-

diaphragm pump, filter, air compressor, filling machne

-

Operating platform:

-

operating platform

-

Control System:

-

electrical cabinets

-

Pipeline system:

-

pipeline valve

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Root

-

Machine Type:

-

production line

-

Marketing Type:

-

New Product 2021

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Product name:

-

1000t Factory Exterior Emulsion Paint Production Line

-

Dosing system:

-

latex feeding tank, vacuum buffer tank, vacuum pump

-

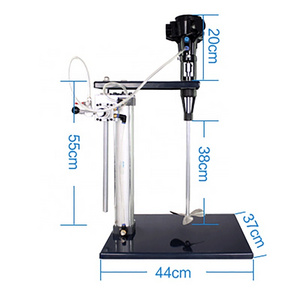

Dispersing system:

-

disperser, dispersering vessel

-

Milling system:

-

basket mill, grinding vessel

-

Tinting system:

-

paddle mixer, tinting vessel

-

Conveying filling:

-

diaphragm pump, filter, air compressor, filling machne

-

Operating platform:

-

operating platform

-

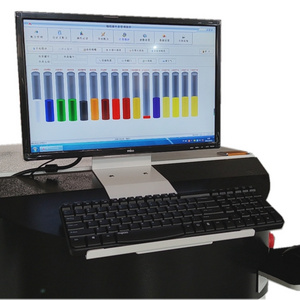

Control System:

-

electrical cabinets

-

Pipeline system:

-

pipeline valve

Product Description

|

S/N

|

System

|

Equipment

|

Quantity

|

Specs

|

|

1

|

Dosing system

|

Powder feeding tank

|

1 piece

|

Volume: 150L;

Material: SS304; Mirror polished

|

|

|

|

Liquid feeding tank

|

1 piece

|

Volume: 150L; Material: SS304; Mirror polished

|

|

|

|

Latex feeding tank

|

1 piece

|

Volume: 150L; Material: SS304; Mirror polished

|

|

|

|

Vacuum buffer tank

|

1 piece

|

Volume: 15L; Material: SS304; Mirror polished

|

|

|

|

Vacuum pump

|

1 set

|

4kw, water-ring vacuum pump

|

|

2

|

Dispersing system

|

Disperser

|

1 set

|

15kw, 0-1440rpm, frequency control, mechanical seal

|

|

|

|

Dispersing vessel

|

1 piece

|

600L, single layer; SS304; Mirror polished; Vacuumized

|

|

3

|

Milling system

|

Basket Mill

|

1 set

|

22kw, 0-1440RPM, Frequency control, mechanical seal

|

|

|

|

Grinding vessel

|

1 piece

|

600L, double layer with cooling jacket, SS304, mirror polished, vacuumized

|

|

4

|

Tinting system

|

Paddle Mixer

|

1 set

|

5.5KW, 65rpm, with seal configuration

|

|

|

|

Tinting vessel

|

1 set

|

1200L, single layer, SS304, mirror polished, vacuumized

|

|

5

|

Conveying system

|

Diaphragm pump

|

1 set

|

DN40 pneumatic diaphragm pump

|

|

|

|

Filter

|

1 set

|

quick-open type bag filter, SS304, mirror polished

|

|

|

|

Air compressor

|

1 set

|

Air supply offered by customer

|

|

|

|

Filling machine

|

1 set

|

semi-automatic paint filling machine

|

|

6

|

Operation platform

|

Operation platform

|

1 set

|

5x3x1.8(m), stainless steel handrail, pattern aluminum platform

|

|

7

|

Control system

|

Electrical cabinets

|

1 set

|

Composite structure, with on-site operation box to realize operation near machine

|

|

8

|

Pipeline system

|

Pipelines & Valves

|

1 set

|

Sanitary ball valve and pipeline, mirror polishing, stainless steel flexible hose for inner lining

|

Introduction:

Based on different material, there are many types of mixing, shearing, dispersing vessels or compound vessels to be selected. We could design the agitator type based on customer material property.

Based on different material, there are many types of mixing, shearing, dispersing vessels or compound vessels to be selected. We could design the agitator type based on customer material property.

Packing & Delivery

Dismantle off the all the speed reducer and motor

Dismantle off the mixing parts

Do inner fixing to avoid damage during sea shipping

Motors, speed reducers, and other dismantle parts packed into plywood cases

Vessel body covered with water-proof film to prevent the vessel body during sea shipping

Vessel body covered with water-proof film to prevent the vessel body during sea shipping

Thank Tanks/Vessels/Kettles will be packed into plywood case with sea-worthy packing.

Production Process

As a member of Root Group, Shanghai Root Mechanical and Electrical Equipment Co., Ltd focused on the research, design and manufacturing of wet grinding machinery. Owning 10 years experience in wet grinding field, Root is your best choice for laboratory sand mill, industrial sand mill, three roller mill and basket mill, auxiliary machines such as disperser and mixer.With cooperation with university, experts and experienced engineers, Root has been concentrated in technique of wet grinding machine since 2000.

Now Root wet grinding mills are applied in more than 20 countries, serving for factory production of paint, ink, dye, magnetic material, paste, agriculture chemicals, adhesion, cosmetics, ceramic etc. With own modern Nano Laboratory and manufacturing factory, Root could provide clients with the most suitable solution for complete wet grinding production mills.Great thanks for all supports and trust from new or old clients. ROOT will consistently make the quality and reputation as the premise of all our development, and make contributions to the development of wet grinding machine worldwide.

Root Nano Lab offers free experiment for customers. Now Root Nano Lab has testing equipment including:

1. Bettersize micron size particle sizer, PSS nano-size particle sizer

2. microscope

3. viscosity testing equipment

4. PH value testing equipment,

5. disperse dye diffusity testing equipment

6. and all the agents, anti-foms etc.

All these equipment will help customer to get ideal experiment result for whichever product they have. All the experiment result

can be scaled up to industrial production.Root Nano Lab has equipped with Root lab series sand mills and disperser: RT-FS1.5,

RT-0.2CD, RT-0.5AD, RT-0.5BJD, RT-1.0BJ, RT-1.0BDD, which could satisfy for experiment requirements of different material,

different feeding size, different viscosity and different finish size etc.

1. Bettersize micron size particle sizer, PSS nano-size particle sizer

2. microscope

3. viscosity testing equipment

4. PH value testing equipment,

5. disperse dye diffusity testing equipment

6. and all the agents, anti-foms etc.

All these equipment will help customer to get ideal experiment result for whichever product they have. All the experiment result

can be scaled up to industrial production.Root Nano Lab has equipped with Root lab series sand mills and disperser: RT-FS1.5,

RT-0.2CD, RT-0.5AD, RT-0.5BJD, RT-1.0BJ, RT-1.0BDD, which could satisfy for experiment requirements of different material,

different feeding size, different viscosity and different finish size etc.

ROOT GROUP MARKETING CENTER

Hot Searches