- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Powerjet

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

85 mm

-

Screw Heating Power(kW):

-

11 kW

-

Extruder Motor Power(kW):

-

30 kW

-

Mold Platen Size(Width)(mm):

-

580 mm

-

Mold Platen Size(Height)(mm):

-

400 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

3 m³/min

-

Die Head Heating Power(kW):

-

21 kW

-

Accumulator Capacity(L):

-

130 L

-

Power (kW):

-

21

-

Weight (T):

-

6

-

Processing Type:

-

Extruding Machine

-

Double station:

-

Siemens PLC

-

Automatic Grade:

-

All auto

-

Product Type:

-

extrusion blow molding machines

-

Function:

-

Automatic Plastic Bottle Making Machine Line

-

Usage:

-

Plastic Extrusion

-

Color:

-

White+green

-

Suitable bottle:

-

1-10L

-

Delivery Time:

-

50~100 Days

-

Certification:

-

CE IS09001

Quick Details

-

Clamping Force (kN):

-

110

-

Output (kg/h):

-

125 kg/h

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Powerjet

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

85 mm

-

Screw Heating Power(kW):

-

11 kW

-

Extruder Motor Power(kW):

-

30 kW

-

Mold Platen Size(Width)(mm):

-

580 mm

-

Mold Platen Size(Height)(mm):

-

400 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

3 m³/min

-

Die Head Heating Power(kW):

-

21 kW

-

Accumulator Capacity(L):

-

130 L

-

Power (kW):

-

21

-

Weight (T):

-

6

-

Processing Type:

-

Extruding Machine

-

Double station:

-

Siemens PLC

-

Automatic Grade:

-

All auto

-

Product Type:

-

extrusion blow molding machines

-

Function:

-

Automatic Plastic Bottle Making Machine Line

-

Usage:

-

Plastic Extrusion

-

Color:

-

White+green

-

Suitable bottle:

-

1-10L

-

Delivery Time:

-

50~100 Days

-

Certification:

-

CE IS09001

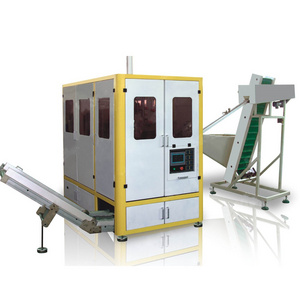

4 cavity 20 litre plastic bottles jerry cans jars gallons blow molding machine making machine

EXTRUSION BLOW SERIES

HIGH SPEED DOUBLE STATION EXTRUSION BLOW MOLDING MACHINE EB30U/EB70U

Powerjet Double Station Extrusion Blow Molding Machine EB30U/EB70U is specialized for manufacturing bottles and containers which under 10L.

FEATURES:

1:Toggle balance clamping structure, with platen opening & clamping and mold platen movement by linear guide, to achieve low friction and high speed.

2:Based on the Finite Element Analysis design, and platen, toggle and platen frame made in high intensity nodular cast iron.

3:High speed mold clamping oil cylinder with differential speed function, and high speed mold moving cylinder with special anti-shock cushion valve structure.

4:Specially designed screw with high L/D ratio insures good plasticizing and stable extrusion; high precision and no part line die head guarantees customers’ top quality requirement.

5:Multi-screw & multi-die head can be adopted to improve the quality of the product and lower down the cost of material.

6:Multiple-way PID controlled temperature heating is precise and stable.

Description:

| Model | EB70U70 | |

| Max. Product | L | 7 |

| Clamping Force | KN | 84 |

| Max.Mold Size(W*H) | mm | 500*450 |

| Screw Diameter | mm | 70 |

| Screw L/D Ratio | L/D | 25 |

| Screw Rotary Speed | RPM | 75 |

| Extrusion Weight (HDPE) | kg | 80 |

| Extrusion Motor Power | KW | 18.5 |

| Pump Motor Power | KW | 11 |

| Heating Capacity | KW | 15 |

| Operation Pressure | Mpa | 0.6~0.8 |

| Air Consumption | m 3 /min | 2.5 |

| Cooling Water Consumption(25°c) | L/min | 100 |

| Machine Dimensions (LXWXH) | mm | 3900*2260*2500 |

| Machine Weight | kg | 5500 |

About our company:

Powerjet Plastic Machinery Co., LTD Focus On Manufacturing And Development Of Injection Molding Machine And Blow Molding Machine Over 20 Years. Powerjet And Installed Over 18,500 Molding Machines Worldwide And Renowned In " Energy-Saving, High Performance,High Speed,Precision ". Factory in 50,000 square meters, with more than 350 staff members, over 20 branch offices across the country with the advanced experience and lean production.

Our Services & Strength

Setting Up Agent In More Than 20 Countries For Sales And Support

2: Lifetime Support

24 Hours Online Service And Overseas Installation & Maintenance

3: Spare Parts

We Supplying Screw, Motor, Control Panel And Plastic Mold For Machines

4: Operation Training

Support Training To Engineer For Setup, Processing & Troubleshooting

5: Plastic Mold Testing

Provide Testing Mold Service Before Customer Receiving The Machine