- Product Details

- {{item.text}}

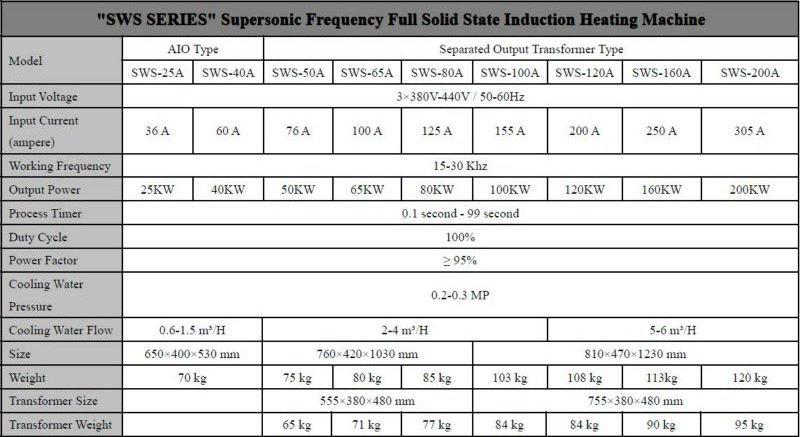

Quick Details

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

JKZ

-

Dimension(L*W*H):

-

650*400*530mm

-

Weight:

-

70 KG

-

Working Temperature Range:

-

1 - 1500 ℃

-

Power:

-

30kw

-

Frequency:

-

15-30khz

-

Inverter:

-

IGBT

-

Power factor:

-

>95%

-

Duty cycle:

-

100%

-

Max input current:

-

60A

-

Water pressure:

-

0.2-0.25kg

-

Origen:

-

Chengdu, Sichuan, China

-

Certification:

-

CE, ISO9001

Quick Details

-

Type:

-

induction heating machine

-

Power Source:

-

Electric

-

Voltage:

-

3*380v, 380V 50-60hz

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

JKZ

-

Dimension(L*W*H):

-

650*400*530mm

-

Weight:

-

70 KG

-

Working Temperature Range:

-

1 - 1500 ℃

-

Power:

-

30kw

-

Frequency:

-

15-30khz

-

Inverter:

-

IGBT

-

Power factor:

-

>95%

-

Duty cycle:

-

100%

-

Max input current:

-

60A

-

Water pressure:

-

0.2-0.25kg

-

Origen:

-

Chengdu, Sichuan, China

-

Certification:

-

CE, ISO9001

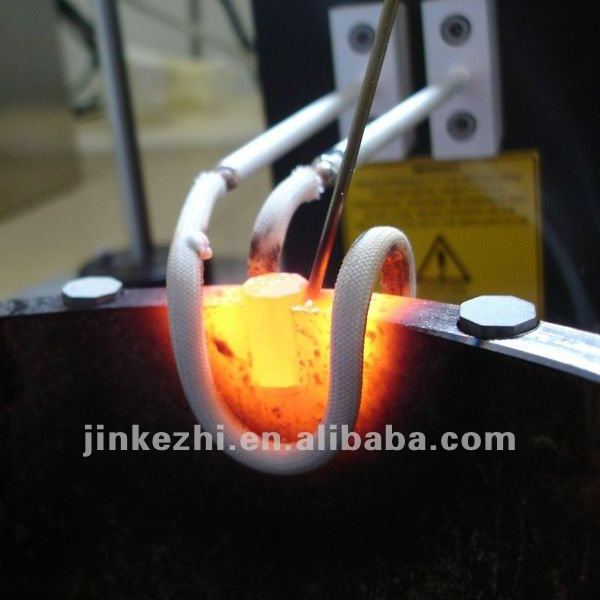

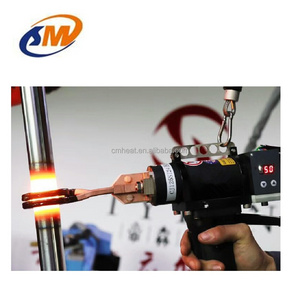

Portable induction hardening machine

Application Ran

ge

:

1. Hot forging for various hardware and tools, such as plier, wrench, hammer, ax, screwing tools and shear (orchard shear).

2. Hot forging and quenching for various automobile and motorcycle fittings, such as crankshaft, connecting rod, piston pin, chain wheel,aluminum wheel, valve, rock arm shaft, semi drive shaft, small shaft and small fork.

3. Quenching for electric tools, such as gear and axes.

4. Quenching for machine tools, such as lathe deck and guide rail.

5. Quenching for various hardware metal parts and machined parts, such as shaft, gear (chain wheel), cam, chuck and clamp, etc.

6. Hot forging for hardware molds, such as small-size mold, accessory of mold and inner hole of mold.

7. Other metal products.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Professional R & D team And designing team, famous technical experts of rich induction heating knowledge, Every product own intellectual property right. These make us the one of leader of advanced induction heating technology in China.

|

Packaging

|

|

|

|

Size

|

940*520*1130mm

|

|

|

Weight

|

115kgs

|

|

|

Packaging Details

|

igbt electromagnetic induction heating equipment packing material is plywood box, suitable for export.

|

|

FAQ

Q1, what is your application?

For example: induction brazing/ billets forging heating/ heat treatment/ melting furnace

Q2, what is the workpiece metal material/ dimention?

Forexample:steel/stainless steel/brass/copper/Aluminum,etc

diameter, length, thickness, heating zone length, heat treatment layer depth

Q3, What is the request heating temperature and time?

For example: heating temperature 1000C, 500kgs/hour

Q4, Does your company work on OEM?

Yes, we have a professional design and technical team to do the customization

Q5, What’s the delivery time after the order is placed?

We arrange the shipment in 3-15 days for standard machine. It takes us more days for customized machines

Q6, How about the warranty?

The warranty is one year by offering spare parts for free and we provide lifelong maintenance.

Q7, What can you provide after service?

We provide machine running video, instruction manual in English, spare parts Also

our engineers are available to clients’ factory and technical training.