- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

3200 mm

-

Backgauge Travel (mm):

-

10 - 750 mm

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

WEIYA

-

Power (kW):

-

11 kW

-

Weight (KG):

-

18000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3900*1900*2050

-

Year:

-

2024

-

Marketing Type:

-

New Product 2024

-

Cutting material:

-

Metal .alloy Metal .aluminum

-

Cutting length:

-

3200mm Metal Shears

-

Cutting thickness:

-

8mm Metal Cutter

-

Throat depth:

-

100

-

Control system:

-

Estun

-

Function:

-

Metal Hydraulic Guillotine Shears

-

Hydraulic Valve:

-

Hoerbigger Swiss

-

Main Motor:

-

Siemens Germany

-

After-sales Service Provided:

-

Online Support

Quick Details

-

Max. Cutting Width (mm):

-

3200

-

Max. Cutting Thickness (mm):

-

8 mm

-

Shearing Angle:

-

2°, 0.5-2°

-

Blade Length (mm):

-

3200 mm

-

Backgauge Travel (mm):

-

10 - 750 mm

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

WEIYA

-

Power (kW):

-

11 kW

-

Weight (KG):

-

18000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3900*1900*2050

-

Year:

-

2024

-

Marketing Type:

-

New Product 2024

-

Cutting material:

-

Metal .alloy Metal .aluminum

-

Cutting length:

-

3200mm Metal Shears

-

Cutting thickness:

-

8mm Metal Cutter

-

Throat depth:

-

100

-

Control system:

-

Estun

-

Function:

-

Metal Hydraulic Guillotine Shears

-

Hydraulic Valve:

-

Hoerbigger Swiss

-

Main Motor:

-

Siemens Germany

-

After-sales Service Provided:

-

Online Support

Products Description

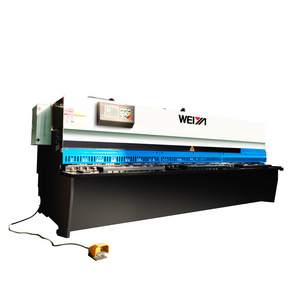

CNC Shearing machine

WEIYA guillotine shear stands as a prime example of a project that combines Chinese creativity, design prowess, and innovation with the dependable quality of leading Chinese and European components.

This fusion brings forth state-of-the-art technology and streamlined design, guaranteeing the machine's durability, cutting

precision, and unparalleled quality. It is outfitted with an extensive selection of standard features but also allows for the easy addition of optional extras to meet specific demands.

Its solid one-piece structure provides exceptional stability and precise cutting capabilities. Furthermore, its design has been carefully optimized to enhance both functionality and operational efficiency, demonstrating a meticulous attention to detail.

This fusion brings forth state-of-the-art technology and streamlined design, guaranteeing the machine's durability, cutting

precision, and unparalleled quality. It is outfitted with an extensive selection of standard features but also allows for the easy addition of optional extras to meet specific demands.

Its solid one-piece structure provides exceptional stability and precise cutting capabilities. Furthermore, its design has been carefully optimized to enhance both functionality and operational efficiency, demonstrating a meticulous attention to detail.

Standard Accessories

1. E21S-Estun: digital monitor to display the position of the back gauge 2. REXROTH, Germany hydraulic system

3. SUNNY, USA oil pump with slide-in pipes joints

4. Back gauge is moved with T-screw shaft, guided by rod-shaft and driven by AC motor

5. Motorized adjustment of blade gap and shearing angle

6. Hydraulic hold downs with sequential operation

7. Moveable foot switch

8. Finger guard

9. Interchangeable blades with four cutting edges

10. One set of standard blade (upper and lower) materials is 6CrW2Si

11. Front support arms with length 1000mm (at least 3pcs)

12. Ball worktable, reduce the contact between sheet plate and machine work table

13. Often-used internal hexagonal key spanner for adjusting blades

14. Comprehensive instruction & maintenance manual

3. SUNNY, USA oil pump with slide-in pipes joints

4. Back gauge is moved with T-screw shaft, guided by rod-shaft and driven by AC motor

5. Motorized adjustment of blade gap and shearing angle

6. Hydraulic hold downs with sequential operation

7. Moveable foot switch

8. Finger guard

9. Interchangeable blades with four cutting edges

10. One set of standard blade (upper and lower) materials is 6CrW2Si

11. Front support arms with length 1000mm (at least 3pcs)

12. Ball worktable, reduce the contact between sheet plate and machine work table

13. Often-used internal hexagonal key spanner for adjusting blades

14. Comprehensive instruction & maintenance manual

Optional Accessories

1. DAC360 , Netherlands CNC controller

2. Backgauge with ball screw and linear guideway ,drive by AC Servo motor

3. Automatic cutting angle and blade gap

4. 6CrW2Si blade changed to Cr12MoV blade (for cutting stainless steel)

5. Pneumatic out table device for cutting piece falling smooth.

Hot Searches