- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

20-300 mm

-

Place of Origin:

-

Hebei,China

-

Brand Name:

-

XINNUO

-

Voltage:

-

380 V ,50 Hz, 3 Phase or as require'

-

Dimension(L*W*H):

-

45000*2500*2600 mm

-

Weight:

-

17000 kg

-

Feeding width:

-

1220mm or as your need

-

Marketing Type:

-

Hot Product 2022

-

total power:

-

30 kw

-

Core thickness:

-

20-300 mm

-

Main Frame of plate forming machine:

-

300 mm H-Beam

-

Backboard Thickness of plate former:

-

20 mm

-

Roller Diameter:

-

80 mm

-

After-sales Service Provided:

-

Engineers avaliable

-

Cutting blade material:

-

Cr 12 Mov

-

Roller material:

-

45#steel Chrome Plated

-

Control system:

-

PLC Control

-

Certification:

-

TUV,ISO

Quick Details

-

Type:

-

roll forming machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

0-6 m/min

-

Rolling thinckness:

-

20-300 mm

-

Place of Origin:

-

Hebei,China

-

Brand Name:

-

XINNUO

-

Voltage:

-

380 V ,50 Hz, 3 Phase or as require'

-

Dimension(L*W*H):

-

45000*2500*2600 mm

-

Weight:

-

17000 kg

-

Feeding width:

-

1220mm or as your need

-

Marketing Type:

-

Hot Product 2022

-

total power:

-

30 kw

-

Core thickness:

-

20-300 mm

-

Main Frame of plate forming machine:

-

300 mm H-Beam

-

Backboard Thickness of plate former:

-

20 mm

-

Roller Diameter:

-

80 mm

-

After-sales Service Provided:

-

Engineers avaliable

-

Cutting blade material:

-

Cr 12 Mov

-

Roller material:

-

45#steel Chrome Plated

-

Control system:

-

PLC Control

-

Certification:

-

TUV,ISO

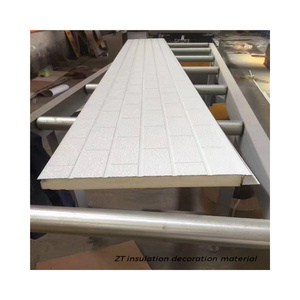

Products Description

Other machines

We can produce too many types roofing panels roll forming machine ,especially according to your request to produce.you need provide panel drawing,feeding width,effective width,and materials thickness,then we can send you more machine details.please feel free contact me.

Application

Sample

Specification

|

No.

|

Name

|

Components

|

Quality

|

Remark

|

|

Roof panel roll forming machine

|

Roof panel roll forming machine

|

Manual Decoiler

|

1 set

|

Capacity 5 tons

|

|

|

|

Steel cutting device

|

1 set

|

Electric

|

|

|

|

Single layer roll forming machine

|

1 set

|

|

|

Feeding machine

|

Feeding machine

|

Steel uncoiler

|

2 sets

|

|

|

|

|

Ribs forming sets

|

2 sets

|

Upper/Lower each 1 set

|

|

|

|

Electrical cutting sheet set

|

2 sets

|

Upper/Lower each 1 set

|

|

|

|

Core material conveying device

|

1 set

|

|

|

Main sandwich panel part

|

Main sandwich panel part

|

Glue pump

|

1 set

|

4 glue pumps, 2 motors, 2 inverters

|

|

|

|

Pneumatic glue device

|

3 sets

|

Upper/Middle/Lower each 1 set

|

|

|

|

Sandwich main part and transmission

|

1 set

|

|

|

|

|

Infrared heating device

|

6 set

|

|

|

|

|

Electrical edge joint forming set

|

1 set

|

|

|

PLC computer control

|

|

|

1 set

|

|

|

Cutting set

|

|

|

1 set

|

Automatic cutting

|

|

Receive stacking

|

|

|

1 set

|

6 cutters

|

Detailed technology

packaging and shipping

Our Advantages

Large gantry milling machine

Our factory uses a 13-meter large gantry milling machine. This equipment is used to process the main frame of the machine, so that the large frame has a higher flatness and better levelness, and the accuracy can reach 0.05 mm. Effectively ensure product stability.

Spray paint workshop

Using environmentally friendly resin paint, two-coating and two-spray new technology, the paint surface has good adhesion, durability, corrosion resistance, aging resistance and no fading.

Shot blasting machine

The use of large-scale shot blasting with six heads for rust removal and the deep treatment of the overall frame improves the intrinsic quality of the paint film and steel and prolongs its service life.

Electrical control

The electrical control systems of the machines in our factory are all programmed and designed by our factory engineers.If there is a problem with the operation of the travel electrical appliance,the electrical engineer can assist the customer through video to ensure that the problem is solved in time.

Machining

Our factory has purchased more than 50 processing machine, including CNC machining centers, CNC lathes, grinding machines, milling machines , sawing machines, drilling machines, etc.,to ensure that each component is processed by itself, and undergoes strict quality inspection to ensure product quality.

Data milling machine

All the hole positions of the vertical plate of the computer C-shaped steel equipment ,which is a hot-selling product of our

factory ,are processed by this equipment ,and the hole positions are accurate . The vertical plates of all C-section steel equipment are interchangeable for after-sales convenience.

factory ,are processed by this equipment ,and the hole positions are accurate . The vertical plates of all C-section steel equipment are interchangeable for after-sales convenience.

Hot Searches