- Product Details

- {{item.text}}

Quick Details

-

Power:

-

22kw

-

Weight:

-

2Ton

-

Dimension(L*W*H):

-

5500*2050*2300mm

-

Warranty:

-

12 Months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine material:

-

Stainless Steel 201/SUS 304

-

Application:

-

Pineapple, jackfruit, Carrot, Okra

-

Function:

-

Low temperature vacuum frying

-

Energy:

-

Steam

-

Name:

-

French Fry Sale Shrimp Banana Chip Vacuum Fryer Machine

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

United States

-

Certification:

-

CE Certificate

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TINDO

-

Voltage:

-

380V

-

Power:

-

22kw

-

Weight:

-

2Ton

-

Dimension(L*W*H):

-

5500*2050*2300mm

-

Warranty:

-

12 Months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine material:

-

Stainless Steel 201/SUS 304

-

Application:

-

Pineapple, jackfruit, Carrot, Okra

-

Function:

-

Low temperature vacuum frying

-

Energy:

-

Steam

-

Name:

-

French Fry Sale Shrimp Banana Chip Vacuum Fryer Machine

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

United States

-

Certification:

-

CE Certificate

vacuum frying banana green crispy plantains chips making machine

vacuum frying banana green crispy plantains chips making machine, as known as an automatic vacuum fryer, is an integrated intelligent vacuum frying machine with an integrated design of frying, deoiling, dehydration and oil filtration. It is continuously completed under a vacuum.

The final vacuum fried pumpkin has a low oil content and negative pressure state. Food processing under the conditions can reduce or even avoid the harm caused by oxidation (such as fatty acid failure, enzymatic browning, and other oxidative deterioration).

How to select a good vacuum frying banana green crispy plantains chips making machine(Vacuum fryer machine)?

1, Pay more attention to the vacuum level.

The vacuum level determines the frying time of each batch. The vacuum system(vacuum pumps with condenser) design affects the vacuum level.

2, Oil temperature controlling.

Oil temperature should be accurately controlled. This is affected by the oil pump circulating system and the heating system. The oil temperature keeps accurately and the smaller the oil temperature change, the smaller the impact on fried foods, and you can get high-quality foods with uniform color and taste.

3, Frying time per batch.

The frying time shorter, the final food oil content the less, and the color more original. Also, the frying capacity is bigger.

If the Tindo vacuum fryer uses 15 minutes for the banana chips 70Kgs input, and another brand process 120kgs need 35 minutes, which brand you will choose?

Parameters of VF250 vacuum frying banana green crispy plantains chips making machine

|

Model Parameter |

VF250 |

||

|

Processing capcacity (material: Kg/batch) |

50~110kg(different raw materials, will have different capacity) |

||

|

Basket volume(L) |

250L |

||

|

Processing time(min/batch) |

Around 20-30 |

||

|

Vacuum degree(MPa)(at water temperature 15 ℃ ) |

- 0.096~0.098 |

||

|

Oil temperature( ℃ ) |

Environment temp~120 |

||

|

Heating

|

Heating source |

steam |

|

|

Steam consumption(Kg/h) |

250 |

||

|

Interlining steam pressure( MPa) |

≤0.2 |

||

|

Heat exchanger steam pressure(MPa) |

0.4~0.5 |

||

|

Steam entrance(mm) |

DN40 |

||

|

|

Steam exit (mm) |

DN25 |

|

|

Heating method |

Oil pump outside loop and interlayer |

||

|

Deoiling speed n/min |

0~300 |

||

|

Cooling water consumption(T/H) |

25 |

||

|

Cooling water entrance/exit diameter(mm) |

DN50/DN50 |

||

|

Vacuum pump cooling water entrance(mm) |

DN20 |

||

|

power |

Volt |

380V/3phase 50Hz |

|

|

Total power(Kw) |

16.5KW |

||

1, Tindo vacuum fryer vacuum level can be 300-500Pa.(0pa meaning real vacuum)

2, Tindo use a special oil circulating system to make sure the oil temperature controlled accurately, and heat up speed fast.

3, We prefer to shorter the frying time for frying a reasonable quantity per batch,not large capacity per batch but need very long frying time.

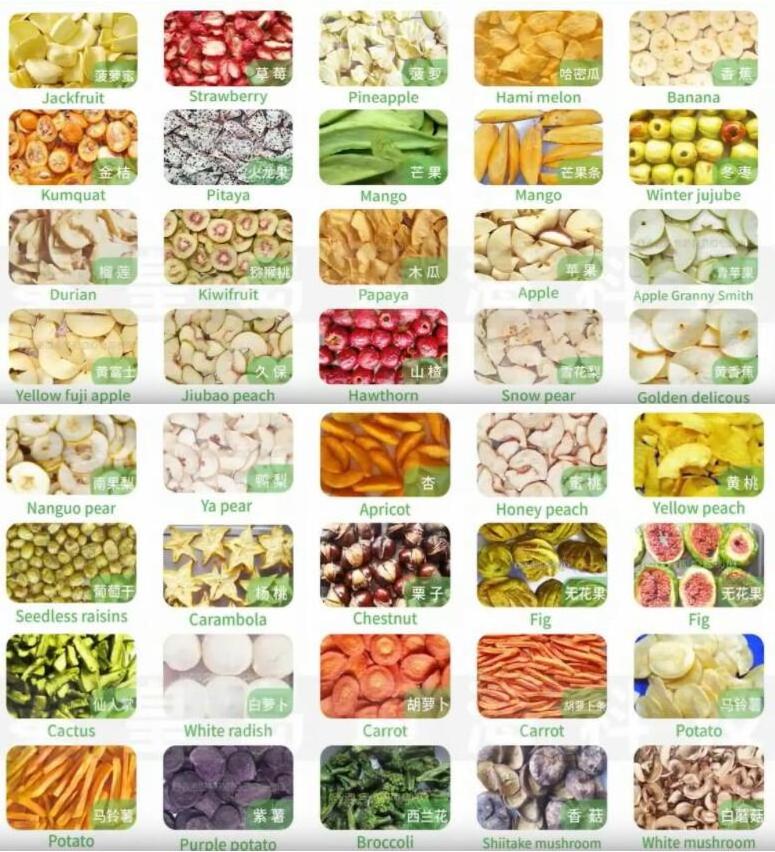

What vegetable or fruits can be processed by this machine?

Flow chart of the vacuum fried vegetable chips making machine

Products screening →washing→peeling& conditioning→slicing →deactivation of enzymes ,cooing →color preservation→water filter→freezing→dipping→frying&deoil→packing.