Description

- Product Details

- {{item.text}}

Quick Details

-

Bonding Strength(Mpa):

-

Standard: ≥0.5

-

Appearance:

-

White or Grey

-

Thickness:

-

2-2.5mm

-

Dosage:

-

2.8-3.5kg/㎡

-

Packing:

-

20kg/bag

-

Shelf life:

-

1 year

-

Keywords:

-

Ceramic Tile Glue tile Adhesive for ceramic tile

-

Mixing Material:

-

Water

-

Mixing Ratio:

-

25:6

Quick Details

-

CAS No.:

-

3824500000

-

Place of Origin:

-

Guangdong, China

-

Application temperature:

-

5℃-40℃

-

Bonding Strength(Mpa):

-

Standard: ≥0.5

-

Appearance:

-

White or Grey

-

Thickness:

-

2-2.5mm

-

Dosage:

-

2.8-3.5kg/㎡

-

Packing:

-

20kg/bag

-

Shelf life:

-

1 year

-

Keywords:

-

Ceramic Tile Glue tile Adhesive for ceramic tile

-

Mixing Material:

-

Water

-

Mixing Ratio:

-

25:6

Product Description

Maydos waterproof Ceramic Tile Glue tile Adhesive for ceramic tile

Where to Use

For floor and ground: To bond ceramic tile or building stone.

Advantages

1. Super bonding power, avoid the hollow caused by ceramic tile which contacted with cement;

2. Stable performance, use directly after mix it with water;

3. Strong water retention capacity, no need to soak the tile or wet the wall. Reduce the dosage of adhesive and the load on the building;

4. Good flexibility, resistant to all kinds of impact;

5. Nontoxic, non-radiant, no irritative odor;

6. Special anti-sagging formula, easier application.

1. Super bonding power, avoid the hollow caused by ceramic tile which contacted with cement;

2. Stable performance, use directly after mix it with water;

3. Strong water retention capacity, no need to soak the tile or wet the wall. Reduce the dosage of adhesive and the load on the building;

4. Good flexibility, resistant to all kinds of impact;

5. Nontoxic, non-radiant, no irritative odor;

6. Special anti-sagging formula, easier application.

|

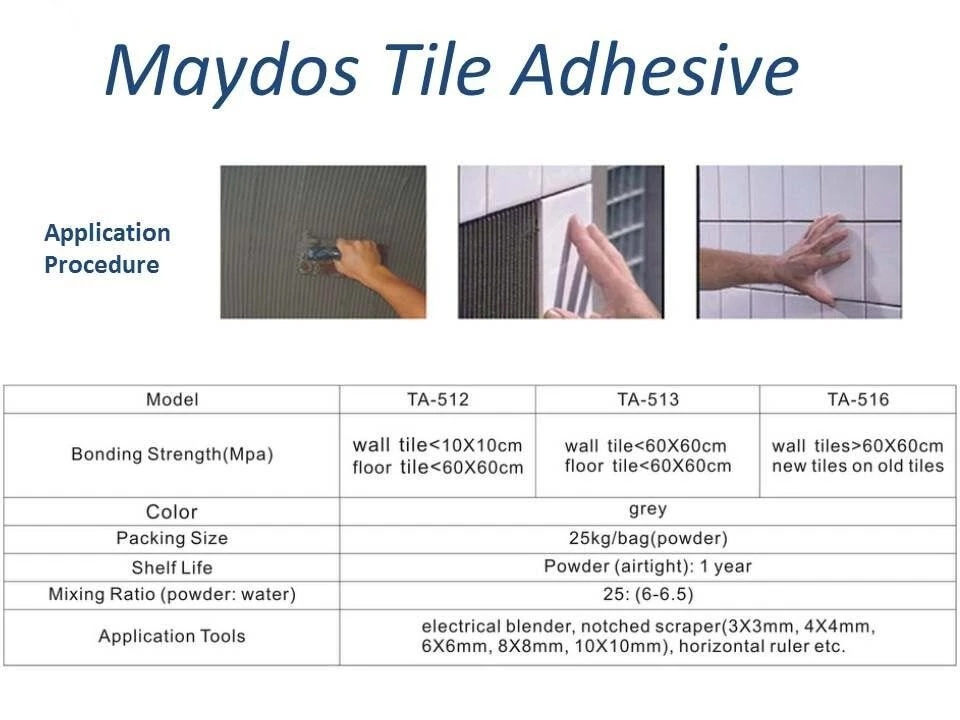

5℃-40℃Application temperature

|

5℃-40℃

|

|

Bonding Strength(Mpa)

|

Standard: ≥0.5

|

|

Thickness

|

2-2.5mm

|

|

Dosage

|

2.8-3.5kg/㎡

|

|

Packing

|

20kg/bag

|

Application

Guidelines

1. Surface Preparation :

·The surface should be vertical, flat, smooth and free of dust, grease and other contaminants.

·The new cement mortar surface should be maintained at least 14 days before the application of the adhesive.

2. Application Methods :

·Mix the powder with water at the ratio of 25:6-6.5, and then use electrical blender to stir evenly.

·Keep the mixture for 5 to 10 minutes, and then stir it again to achieve the best result.

·Finally apply the adhesive on the surface with the notched scraper, and then put the ceramic tile on the surface and press.

· Mixing Ratio (powder: water): 25: (6-6.5)

· Application Tools : electrical blender, notched scraper(3X3mm, 4X4mm, 6X6mm, 8X8mm, 10X10mm), horizontal ruler etc.

1. Surface Preparation :

·The surface should be vertical, flat, smooth and free of dust, grease and other contaminants.

·The new cement mortar surface should be maintained at least 14 days before the application of the adhesive.

2. Application Methods :

·Mix the powder with water at the ratio of 25:6-6.5, and then use electrical blender to stir evenly.

·Keep the mixture for 5 to 10 minutes, and then stir it again to achieve the best result.

·Finally apply the adhesive on the surface with the notched scraper, and then put the ceramic tile on the surface and press.

· Mixing Ratio (powder: water): 25: (6-6.5)

· Application Tools : electrical blender, notched scraper(3X3mm, 4X4mm, 6X6mm, 8X8mm, 10X10mm), horizontal ruler etc.

Notes

1. Application temperature: 5℃-40℃.

2. Control the mixing ratio of powder and water strictly to avoid too thick or too thin and damage its performance.

3. Don’t add water into the dry and hard adhesive mixture and use it again.

4. If the surface and tile’s backside is not even enough, apply some adhesive on the tile’s backside to avoid hollowing.

5. Store in a cool, dry and well-ventilated place.

Hot Searches