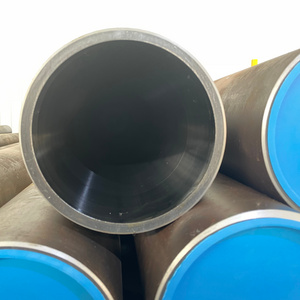

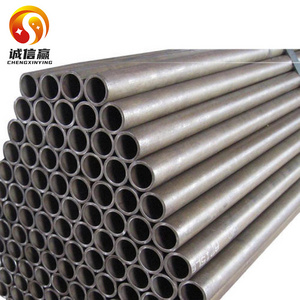

we carry a full inventory of Steel Seamless Pipe and Supply Steel Seamless Tube products in a variety of sizes to meet the High temperature service requirements for applications the Power Plants, Petro Chmical Plants and Refineries industries. Alloy Steel Seamless Pipes and Tube steel pipe can be structural in

hydraulic cylinder,

Petroleum equipment, oil well pipes, precision pipes for automobiles

- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

longford

-

Thickness:

-

3.5 - 40 mm

-

Grade:

-

seamless steel pipe, A335 P9

-

Product name:

-

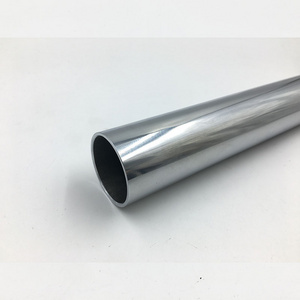

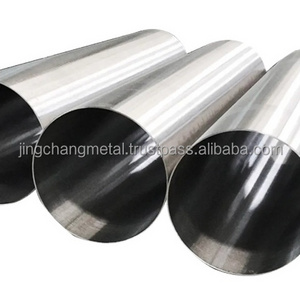

st52 din2391 h8 astm a519 sae4130 honed pipe

-

Surface:

-

Polished

-

Shape:

-

Round Pipe Tube

-

Keyword:

-

honed tube

-

Technology:

-

Hot Rolled Cold Rolled

-

Payment terms:

-

T/T

-

Material:

-

Q195/Q215/Q235/Q345/10#/20#

-

Technique:

-

Hot Rolled

Quick Details

-

Section Shape:

-

Round

-

Surface Treatment:

-

Hot Rolled

-

Tolerance:

-

±15%, ±5%, ±1%

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

longford

-

Thickness:

-

3.5 - 40 mm

-

Grade:

-

seamless steel pipe, A335 P9

-

Product name:

-

st52 din2391 h8 astm a519 sae4130 honed pipe

-

Surface:

-

Polished

-

Shape:

-

Round Pipe Tube

-

Keyword:

-

honed tube

-

Technology:

-

Hot Rolled Cold Rolled

-

Payment terms:

-

T/T

-

Material:

-

Q195/Q215/Q235/Q345/10#/20#

-

Technique:

-

Hot Rolled

Product Description

Product Description

Seamless hydraulic cylinder precision honed tube en10305 e355 h8 h9 st52 stkm13c-t honed pipe

we carry a full inventory of Steel Seamless Pipe and Supply Steel Seamless Tube products in a variety of sizes to meet the High temperature service requirements for applications the Power Plants, Petro Chmical Plants and Refineries industries.Steel Seamless Pipes and Tube steel pipe can be structural in

hydraulic cylinder

.

We Supply Steel Seamless Pipes and Tubes in

10#, 20#, 45#, 16mn, A335 P11, A335 P9, A333, A335 P91, A312, A335 P5

.The grade indicates the testing methods required for a given application. It is critical that structural grades of Carbon Steel Pipe not be used for Pressure or Fluid applications.

|

Specification

|

10#, 20#, 45#, 16mn, A335 P11, A335 P9, A333, A335 P91, A312, A335 P5

|

|

Technology

|

Hot Rolled / Cold Drawn

|

|

Outer Diameter Size

|

55mm - 300mm

|

|

Wall Thickness

|

3.5mm - 40mm

|

|

Length

|

5 To 7 Meters, 09 To 13 Meters, Single Random Length, Double Random Length And Customize Size.

|

|

Dimension

|

All Pipes Is Manufactured and Inspected / Tested to the Relevant standards including ASTM, ASME, API.

|

|

Pipe Ends

|

Plain Ends / Beveled Ends / Coupling

|

|

Value Added Services

|

Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Galavanizing / Heat Treatment

|

Direction for use

-

Production process description

The raw material for rolling seamless carbon steel pipes is round tube blanks, which are cut into blanks by a cutting machine and sent to the furnace for heating via conveyor belts. The billet is fed into the furnace and heated at a temperature of approximately 1200 degrees Celsius. The temperature control in the furnace is a key issue. After the round tube is out of the furnace, it must be pierced through a pressure punching machine. The inner diameter of the steel pipe is determined by the length of the outer diameter of the drill bit of the sizing machine. After the steel pipe is sized, it enters the cooling tower and is cooled by spraying water. After the steel pipe is cooled, it will be straightened. After straightening, the steel pipe is sent to the metal flaw detector (or hydraulic test) by the conveyor belt for internal flaw detection. If there are cracks, bubbles, etc. inside the steel pipe, it will be detected. After the quality inspection of steel pipes, they must be selected strictly, and painted with serial numbers, specifications, and production batch numbers. It is hoisted into the warehouse by a crane.

|

|

|

Grade

|

P-5

|

P-9

|

P-11

|

P-22

|

P-91

|

|

|

Element

|

|

UNS Designation

|

K41545

|

S50400

|

K11597

|

K21590

|

K91560

|

|

|

Carbon

|

|

0.15 max

|

0.15 max

|

0.05 – 0.15

|

0.05 – 0.15

|

0.08 – 0.12

|

V at 0.18 – 0.25

|

|

|

Manganese

|

|

0.30 – 0.60

|

0.30 – 0.60

|

0.30 – 0.60

|

0.30 – 0.60

|

0.30 – 0.60

|

N at 0.030 – 0.070

|

|

|

Phosphorous, max

|

|

0.025

|

0.025

|

0.025

|

0.025

|

0.020

|

Ni at 0.40 max

|

|

|

Sulfur, max

|

|

0.025

|

0.025

|

0.025

|

0.025

|

0.010

|

Al at 0.02 max

|

|

|

Silicon

|

|

0.50 max

|

0.25 – 1.00

|

0.50 – 1.00

|

0.50 max

|

0.20 -0.50

|

Cb at 0.06 – 0.10

|

|

|

Chromium

|

|

4.00 – 6.00

|

8.00 – 10.00

|

1.00 – 1.50

|

1.90 – 2.60

|

8.00 – 9.50

|

Ti at 0.01 max

|

|

|

Molybdenum

|

|

0.45 -0.65

|

0.90 – 1.10

|

0.44 – 0.65

|

0.87 – 1.13

|

0.85 – 1.05

|

Zr at 0.01 max

|

|

Packing & Delivery

2 or 5 coils/bundle. waterproof paper insider, then plastic film, finally hessian cloth or carton, wood pallet or iron pallet. We can also packing as cunstomer's requirement

Hot Searches