- Product Details

- {{item.text}}

Quick Details

-

Power:

-

7200w

-

Voltage:

-

800v

-

Current:

-

4A

-

Warranty:

-

12 Months

Quick Details

-

Place of Origin:

-

Chongqing, China

-

Product name:

-

Multi Electrode Resistivity Tomography System

-

Application:

-

3D Resistivity Imaging Survey Equipment

-

Power:

-

7200w

-

Voltage:

-

800v

-

Current:

-

4A

-

Warranty:

-

12 Months

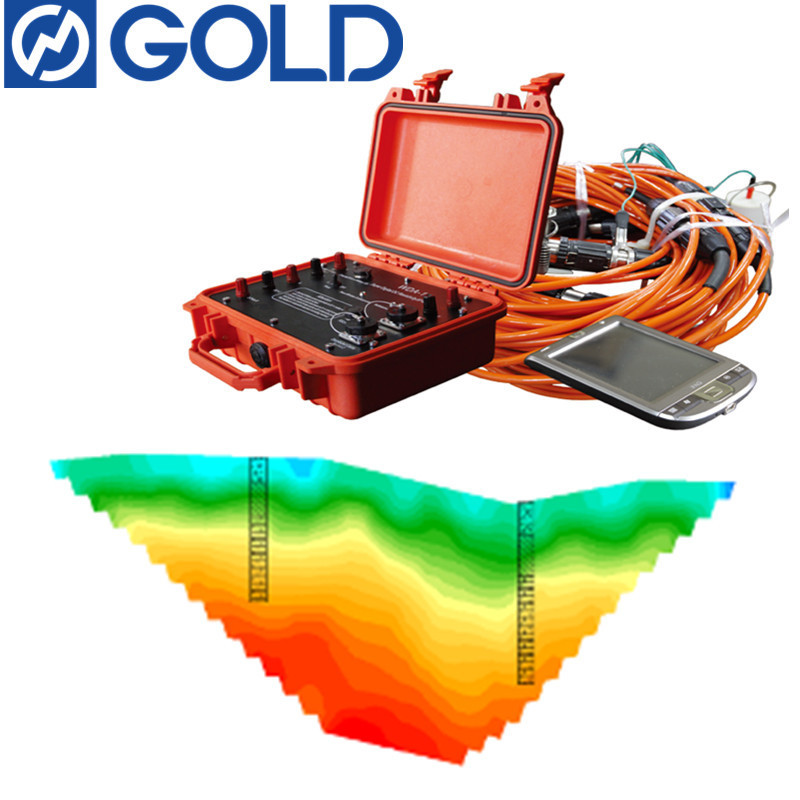

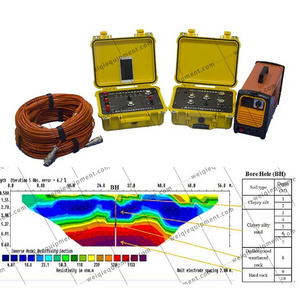

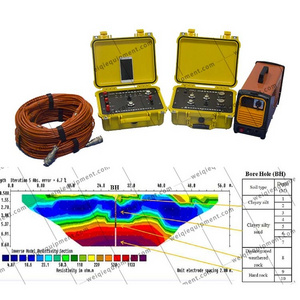

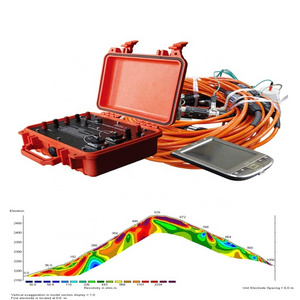

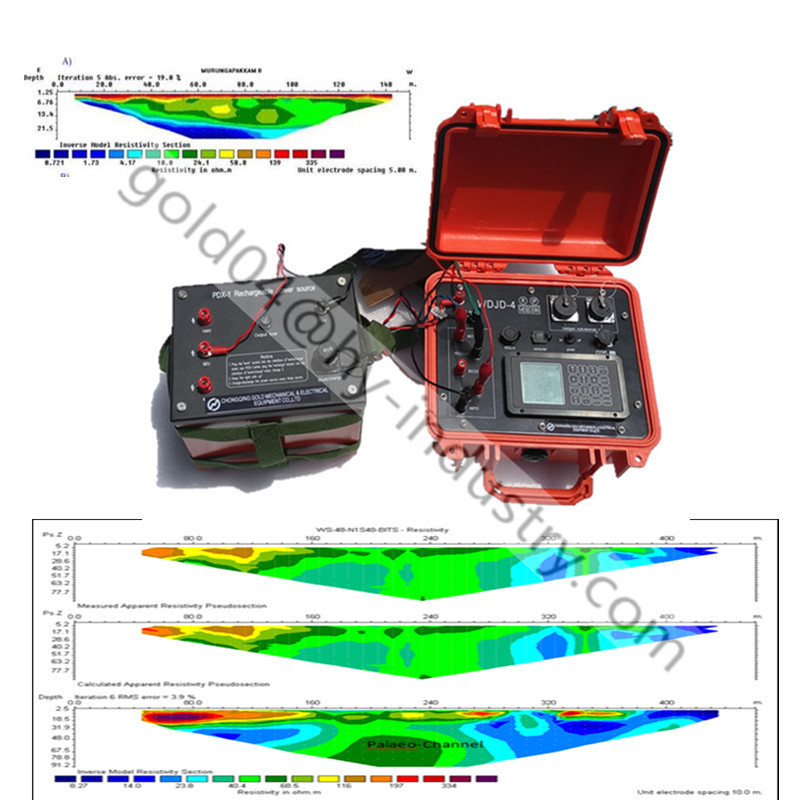

Geo MERIT Multi Electrode Resistivity Tomography System 3D Resistivity Imaging Survey Equipment

Resistivity tomography is a new exploration technology that has emerged in recent years with the development of array spot exploration methods.

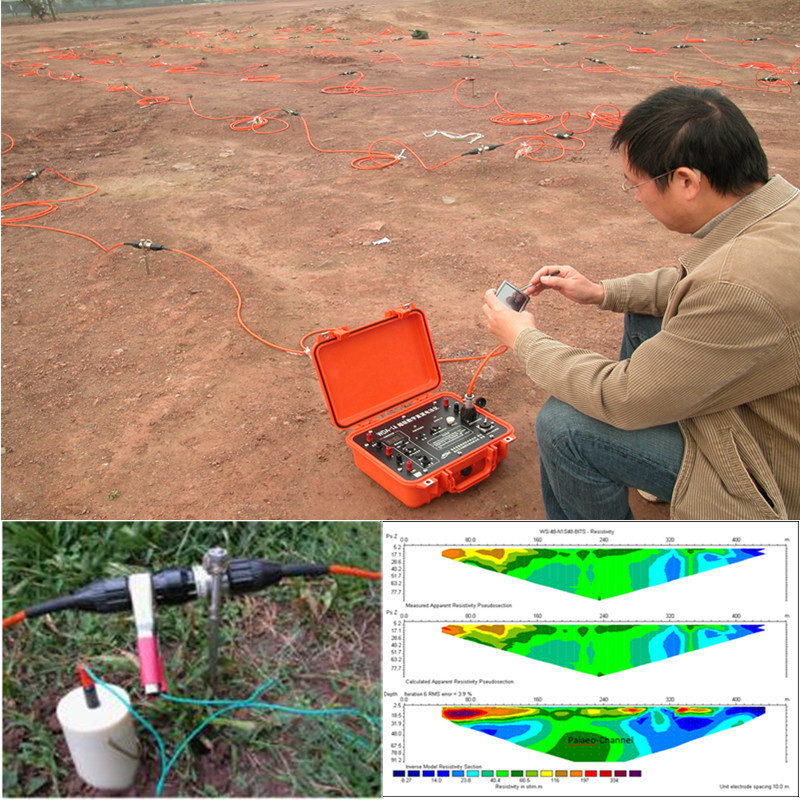

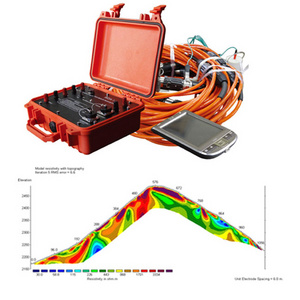

Resistivity imaging belongs to the array point exploration method. It works in the same way as the conventional resistivity method. It combines the section method and the electrical sounding method. It is a two-dimensional detection method. It will be tens to hundreds of times during detection.

The electrodes are arranged on the detection section, and a DC current is manually transmitted to form a stable current field in the ground, and then the process control electrode conversion device and the microcomputer engineering electrical instrument are used to observe and collect data.

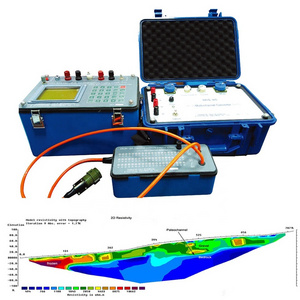

The core of resistivity imaging technology is to use array electrode system in observation, two-dimensional or three-dimensional inversion on data processing, and the distribution of true resistivity from the measured apparent resistivity value. The traditional electromagnetic wave imaging technology has a small penetration depth and low precision, and the seismic wave imaging technology has high construction cost and complicated data acquisition.

Compared with these two methods, resistivity imaging has the characteristics of high efficiency, high speed, low cost, large amount of information, high resolution, large penetration depth, easy to interpret data information, etc. In recent years, it has been obtained in the field of engineering survey widely used.

1. Centralized two-dimensional high-density resistivity cable (optional)

Cable: 32 core, outer diameter Φ6mm

The number of each converter is 2: (the number of electrode taps is 30/root), and the special requirements are specified by the user when ordering.

Tap spacing: specified when the user orders (usually 5m or 10m)

Maximum working voltage: 450V

Maximum working current: 3A

Cable insulation: insulation between any two core wires ≥500MΩ/500V

2. Centralized two-dimensional high-density resistivity electrode (optional)

Copper electrode: Φ12mm×280mm with plug-in card

Quantity: specified by the user when ordering

Distributed high density electrical system:

1, WDA-1, 1B measurement and control host (technical indicators as above)

2, distributed two-dimensional, three-dimensional high-density resistivity, two-dimensional high-density IP switch cable (optional)

Cable: The sheath is a wide temperature polyurethane material with an outer diameter of Φ7mm

Quantity: specified by the user when ordering

Number of cable switch boxes: 10 channels/string (that is, 10 electrodes per string)

Switch box spacing: 1 ~ 10 meters (specified when the user orders)

Switch box size: Φ30mm × 265mm

Maximum working voltage: 1000V

Maximum working current: 4A

Cable insulation: between A and B power supply lines and between them and low voltage lines ≥1000MΩ/2500V

≥500MΩ/500V between low voltage lines

Working temperature: -20 ° C ~ +70 ° C

3, distributed two-dimensional, three-dimensional high-density resistivity, two-dimensional high-density IP switch electrode (optional)

Stainless steel electrode: Φ10mm × 280mm, with stainless steel spring

Please inquiry to below information,I'll reply you soon

Name: Vivienne

Skype:viviennecq

Email: gold04 at hy-industry.com

Tel/whatsapp/wechat:+86-15123029803

Or fill the below table to inquiry