- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

utecs

-

Model Number:

-

HD1450M

-

Voltage:

-

380v,3PH,50HZ

-

Dimension(L*W*H):

-

11200*1600*1800mm, 8057*1800*1800mm

-

Weight:

-

9000 KG

-

Machine name:

-

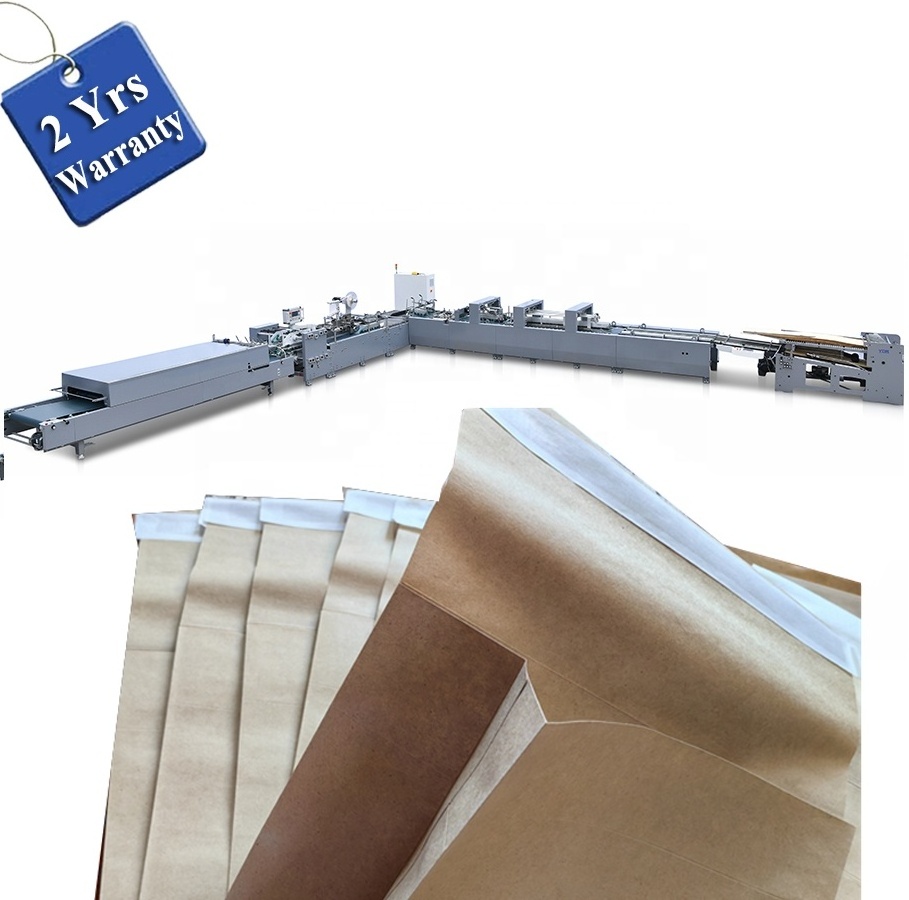

Automatic Pochette Kraft Paper Envelope Bag Making Machine

-

Maxi Paper Sheet:

-

1450*700mm

-

Maxi Envelope Size:

-

750*600mm

-

Mini Envelope Size:

-

260*290mm

-

Paper thickness:

-

120-250GSM

-

Flap glue application:

-

Hot melt spraying glue, double side tape

-

Maxi Speed:

-

100pcs/min

-

Total Power:

-

45kw

-

Function:

-

Making bag

-

Dimension (2 units):

-

11200*1600*1800mm, 8057*1800*1800mm

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Shopping Bag

-

Material:

-

Paper

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

utecs

-

Model Number:

-

HD1450M

-

Voltage:

-

380v,3PH,50HZ

-

Dimension(L*W*H):

-

11200*1600*1800mm, 8057*1800*1800mm

-

Weight:

-

9000 KG

-

Machine name:

-

Automatic Pochette Kraft Paper Envelope Bag Making Machine

-

Maxi Paper Sheet:

-

1450*700mm

-

Maxi Envelope Size:

-

750*600mm

-

Mini Envelope Size:

-

260*290mm

-

Paper thickness:

-

120-250GSM

-

Flap glue application:

-

Hot melt spraying glue, double side tape

-

Maxi Speed:

-

100pcs/min

-

Total Power:

-

45kw

-

Function:

-

Making bag

-

Dimension (2 units):

-

11200*1600*1800mm, 8057*1800*1800mm

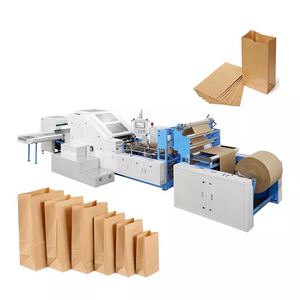

HD1450M Automatic e-commerce packaging Pochette Kraft Gusseted Paper Bag Making Machine with tapes

Video demonstration only for reference

Description:

The machine is professional ly developed to make p ochette kraft paper bags. It comes with the automatic hot melt glue and silicone paper applying system on the flap. The machine features automatic paper sheet feeding, M side forming, gluing, tape applying , counting, delivery and stack ing in just one pass. It is widely used in internet shopping and shipping industry like Amazon.

Feeder section:

1, The suction feeder feeds the paper stably, and the front suction turntable is used to suck the paper forward and the rear suction nozzle to feed forward to realize the advantages of synchronous feeding before and after.

2, The paper feeding and lifting table is divided into two groups of main table, and the two plates of the auxiliary table are used for cross-cycle use, and the feeding and feeding of paper without stopping to ensure stable and efficient production.

3, The large pump 1400 is used, and the high-power sub-pump ensures high-speed and stable production p ower .

Aligning Section

The lengthened side pull gauge has a stable and fast speed for thin paper. It is corrected by the steel ball of the oblique belt. The oblique belt is pulled from the

large bell mouth to the small bell mouth. The paper enters the correction section with the large bell mouth and goes down to the bell mouth to transmit the block

and cooperate with the self-weight steel ball for correction. The thickness of the paper can be corrected, and the speed and accuracy are fast and accurate.

Bag Side M Folding Section

1. The paper is conveyed by rollers, the paper is flat and not easy to wrinkle, and the two sets of upper belts are pressed together for transmission.

2. A set of cold spraying glue r comes with a controller

3. The left M side is folded in two by one-piece modular folding, and the right M side is two-folded by one-piece modular folding, which can adjust the joints and save the time of tuning.

4. The upper pressing drive adopts the pneumatic adjustment of the belt pressing box.

Bag Folding Section

1. Adopt adjustable baffle positioning, left and right can be adjusted.

2. Use the photoelectric encoder to locate the cutter.

3. Servo precise positioning flip system.

4. Precise molding with a special rubber-coated roller clip box.

5. Two sets of hot glue machine (with controller).

Bag Correction Section

1. Correct the crooked phenomenon produced by the output product to improve the accuracy of the product.

2. Cross the ramp runway.

3. The drum is made of rubber-coated material, which has a large friction force and is not easy to slip

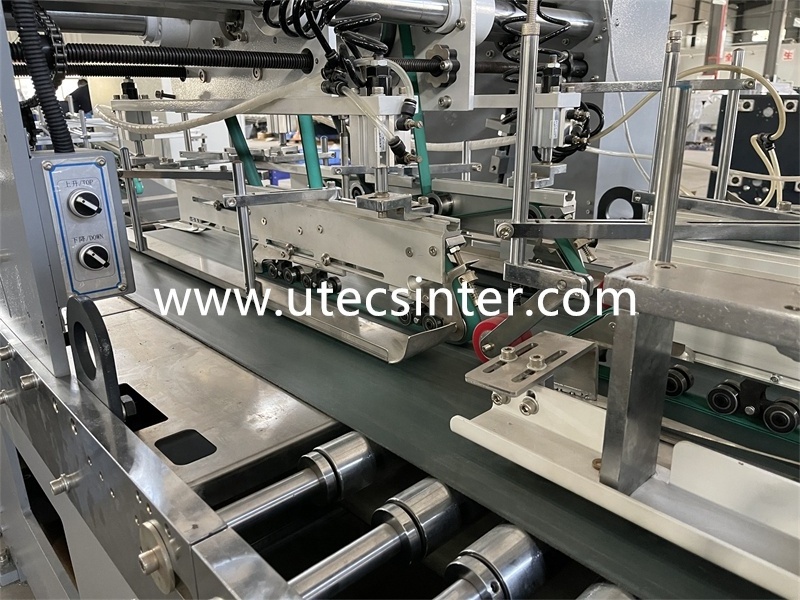

Hot Melt Glue and Tape Application Section

1. Equipped with imported German Sieglin or Italian Joey Longping

Face folded belt.

2. French Hutchinson transmission multi-ribbed belt.

3. The movement of the inner wall panel is automatic electric, labor-saving, time-saving, e asy to operate and high efficiency.

4. Scrape the hot melt adhesive on the surface of the release paper and cut it with a circular knife

Bag Delivery Section

1. The upper and lower belts are each driven by a set of motors, which can be proportionally linked with the host and accurately.

2. The air pressure rear machine can adjust the pressure independently, and the carton can be moderately pressurized to make the bags more nice and clean .

3. The rear machine is lengthened to ensure that the product is not easy to open the glue.

4. The upper and lower transmission of the conveyor belt adopts an active device, and the conveyor belt runs more synchronously.

Parameters:

|

HD1450M |

|

|

Maxi Paper Sheet |

1450*700mm |

|

Maxi Envelope Size |

750*600mm |

|

Mini Envelope Size |

260*290mm |

|

Paper thickness |

120-250GSM |

|

Max-Speed |

100pcs/min |

|

Total Power |

45kw |

|

Weight |

9000kgs |

|

11200*1600*1800mm,8057*1800*1800mm |

Pre-sale Service After-sale Service

A: Inquiry and consulting support A: English manuel and video instruction

B: Sample testing support. B: Your technians can get trained in my factory

C: Invoice and Contract confirmation. C: Engineers available for overseas if necessary

1.Q: What information should i let you know if i want to get a quotation?

A: What is your Max and Min product size in mm?

B: What is your paper thickness in GSM?

C: Some photos of your finished products

2.Q: Are you a manufacturer?

A: Yes we have been manufacturing such machines over 20 years and also we are a professional exporter.

3.Q: What about the payment term?

A: Mostly 30%T/T in advanced, 60% when machine is finished after inspection and last 10% against copy of shipping documents..

4.Q: What is the warranty?

A: Two year warranty after sales (During the warranty period, we respond for free parts dispachment and the buyer is only required to cover the courier express once the machine has any problems. However we do not respond for the consumables and parts broken by mistakingly operation)

5.Q: What is your aftersale service ?

A: Any questions will be responded within 24 hours by email, skype, phone call or Whatsapp/Wechat (+86-18258286679) . In addtion, we have professional engineer available for overseas service. .

6.Q:What is the delivery time?

A: Mostly it takes 10 to 30 workdays after receiving the deposit and confirming the drawing or samples as required.

Container Load and Transport

YOU ARE WELCOME TO CONTACT US ANYTIME AVAILABLE.

Mobile/Whatsapp/Wechat: +86-18258286679

Email: utecs @ utecsinter.com, utecsinter@ gmail.com, danielsuer@ live.com

Skype: danielsuer

Web: www.utecsinter.com