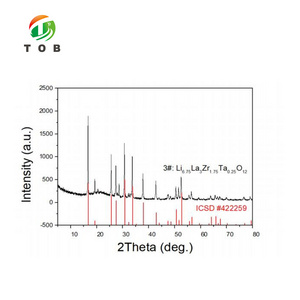

* Used as positive material:

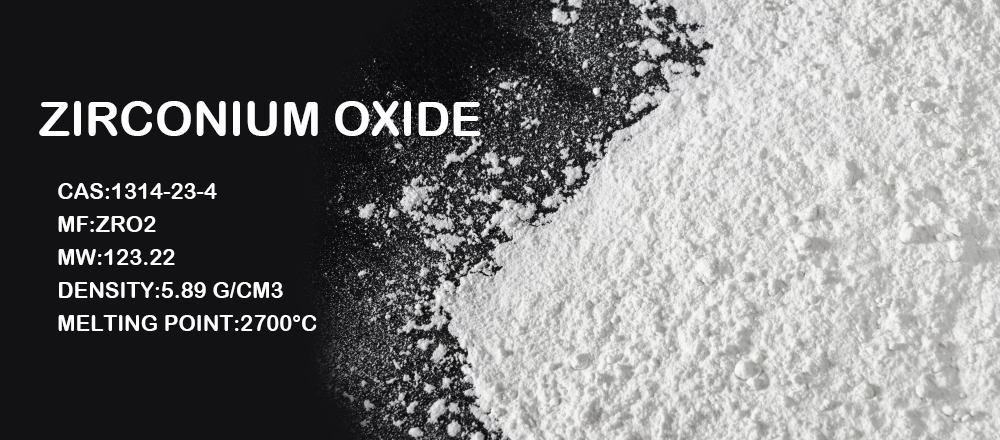

The zirconia powder provided by us has the characteristics of fine size, uniform particle size distribution, no hard

agglomeration, and good sphericity. Doping it into the cathode material of lithium battery can improve the battery's cycle

performance and rate performance. Using its conductivity, high purity zirconia powder can be used for electrode manufacturing in the high-performance solid battery. Zirconia powder (99.99%) can be used as anode materials for lithium batteries, such as nickel cobalt lithium manganate (NiCoMn) O2), lithium cobaltite (LiCoO2), lithium manganate (LiMn2O4).

* For structural members:

TZP, tetragonal zirconia polycrystalline ceramics. When the amount of stabilizer is controlled at a proper amount, t-ZrO2 can be stored in a metastable state to room temperature. Under the action of external force, it can make t-ZrO2 phase change, toughen the non-phase change ZrO2 body, and improve the whole ceramic's fracture line. TZP has excellent mechanical properties such as high strength, high toughness, and high wear resistance. It can be used to make fire-resistant and high-temperature resistant structural parts.

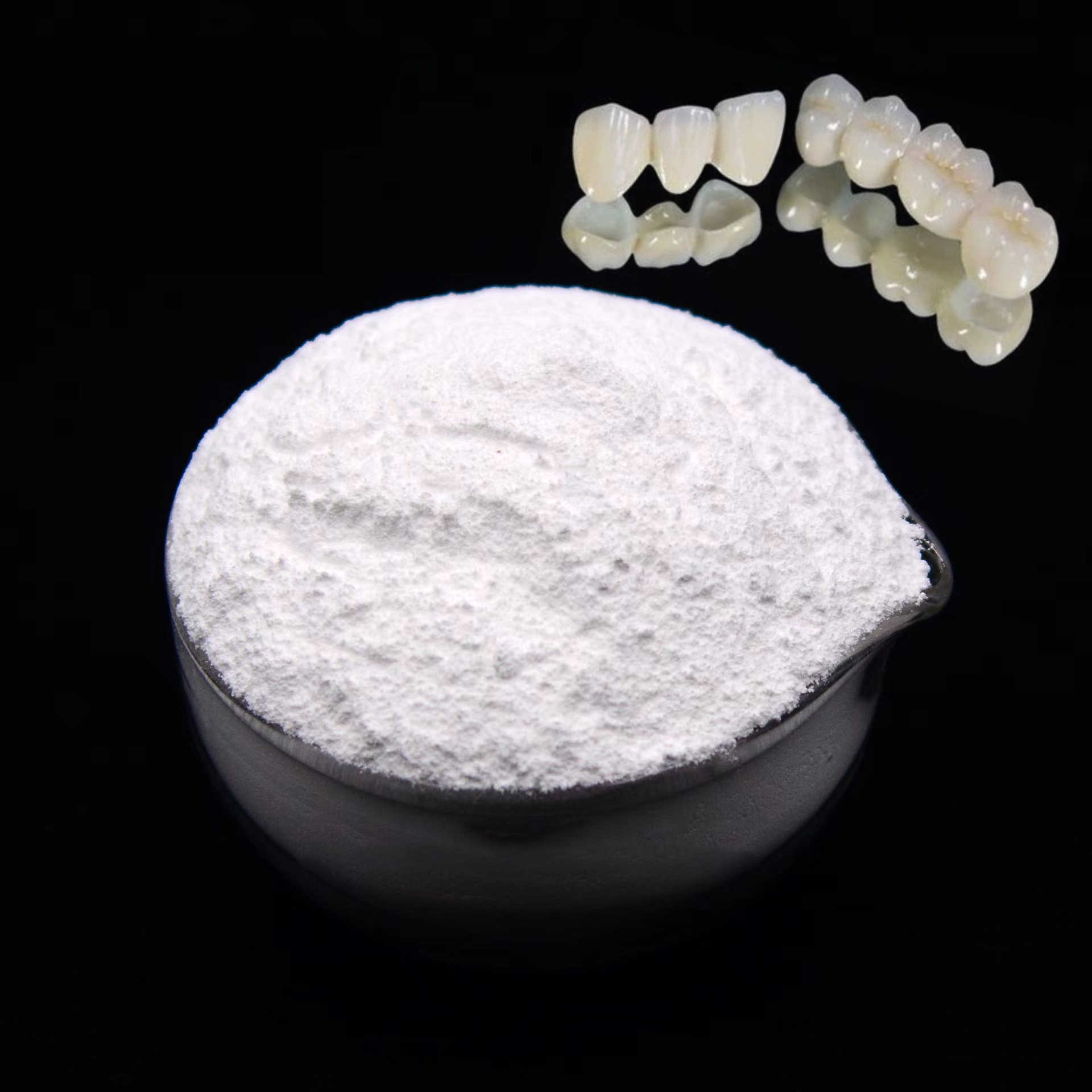

* For porcelain teeth:

Zirconia has high strength, good biocompatibility, no stimulation to the gingiva, and no allergic reaction, so it is very suitable for oral use. Therefore, zirconia powder is often used to make zirconia ceramic teeth. Zirconia all-ceramic teeth are made by computer-aided design, laser scanning, and then controlled by a computer program. It has the characteristics of good translucent appearance, high-density, and intensity, perfect close edge, no gingivitis, no obstruction to X-ray, and so on. It can get long-lasting repair effects in clinical.

* Used to make back panel of mobile phone:

In the 5G era, signal transmission speed must be 1-100 times of 4G. 5G communication use a spectrum of more than 3GHz, and its millimeter-wave wavelength is shorter. Compared with the metal backplane, the mobile phone's ceramic backplane has no interference to the signal and has the incomparable, superior performance of other materials. Among all the ceramic materials, zirconia ceramic has the advantages of high strength, high hardness, acid and alkali resistance, corrosion resistance, and high chemical stability. Simultaneously, it has the characteristics of scratch resistance, no signal shielding, excellent heat dissipation performance, and good appearance effect. Therefore, zirconia has become a new type of mobile phone body material after plastic, metal, and glass. At present, the zirconia ceramic application in mobile phones is mainly composed of a backplate and a fingerprint identification cover plate.

* Used to make zirconia gem:

The production of zirconia gemstones from zirconia powder is an important field of zirconia's deep processing and application. The synthetic cubic zirconia is a hard, colorless, and optically flawless crystal. Because of its low cost, durable, and similar appearance to diamonds, cubic zirconia gemstones have been the most important substitutes for diamonds since 1976.