- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

965*1300*1970

-

Weight (KG):

-

1200

-

Power (kW):

-

4.0

-

Motor:

-

3KW

-

Speed:

-

2800(rpm)

-

Table Travel (X) (mm):

-

160 mm mm

-

Table Travel (Y) (mm):

-

160 mm mm

-

Table Size(mm):

-

965*1300*1970

-

Surface Roughness(μm):

-

0.30 μm μm

-

Certification:

-

CE ISO

Quick Details

-

Wheel Size(mm):

-

260

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

WILA CNC

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

965*1300*1970

-

Weight (KG):

-

1200

-

Power (kW):

-

4.0

-

Motor:

-

3KW

-

Speed:

-

2800(rpm)

-

Table Travel (X) (mm):

-

160 mm mm

-

Table Travel (Y) (mm):

-

160 mm mm

-

Table Size(mm):

-

965*1300*1970

-

Surface Roughness(μm):

-

0.30 μm μm

-

Certification:

-

CE ISO

Products Description

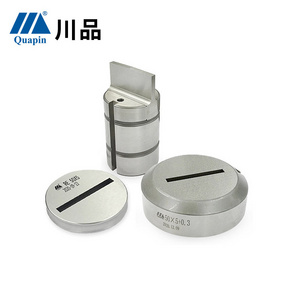

The importance of edge grinding

Only the consistency of the sharp blade to ensure the quality of punching through the mould punch and die with a small amount of grinding to a longer life expectancy, but there is no accurate mould when grinding and quantitative indicators to shows, this has to do with the shape of the mould size and material thickness of the steel plate, but can be judged according to the following three conditions:

(1) check the cutting edge of the mold: if the cutting edge of the mold is worn to a rounded radius of 0.1mm, the mold needs cutting edge grinding.

(2) check the punching quality: the burr of punching becomes larger, and the mould needs to be sharpened.

(3) monitor the noise of punching: the noise of punching becomes larger than usual when the punching machine is punching, so the mould needs to be sharpened.

Only the consistency of the sharp blade to ensure the quality of punching through the mould punch and die with a small amount of grinding to a longer life expectancy, but there is no accurate mould when grinding and quantitative indicators to shows, this has to do with the shape of the mould size and material thickness of the steel plate, but can be judged according to the following three conditions:

(1) check the cutting edge of the mold: if the cutting edge of the mold is worn to a rounded radius of 0.1mm, the mold needs cutting edge grinding.

(2) check the punching quality: the burr of punching becomes larger, and the mould needs to be sharpened.

(3) monitor the noise of punching: the noise of punching becomes larger than usual when the punching machine is punching, so the mould needs to be sharpened.

Main Features

(1) the overall bed is processed once to ensure the verticality between the bench datum and the linear guide datum;

(2) the feeding mechanism adopts imported linear guide rail to feed to ensure the accuracy;

(3) the bottom woring- table adopts the r otating mode of operation and r otate up and down in the different direction

(4) automatic cooling ensures that the repaired edge is not annealed;

(5) the grinding fluid has filtering function;

(6) SUS304 stainless steel sink, beautiful and durable;

(7) quick clamping, quick up and down, easy to operate;

(8) small dimension, once blunt you can grinding

(9) sharper, more economical, more durable, less energy consumption, low grinding cost.

(2) the feeding mechanism adopts imported linear guide rail to feed to ensure the accuracy;

(3) the bottom woring- table adopts the r otating mode of operation and r otate up and down in the different direction

(4) automatic cooling ensures that the repaired edge is not annealed;

(5) the grinding fluid has filtering function;

(6) SUS304 stainless steel sink, beautiful and durable;

(7) quick clamping, quick up and down, easy to operate;

(8) small dimension, once blunt you can grinding

(9) sharper, more economical, more durable, less energy consumption, low grinding cost.

Techical parameters

|

MODEL

|

WILA-200D

|

|

Motor Power

|

4KW

|

|

Motor Speed

|

2890R.P.M

|

|

Maximum grinding outside diameter

|

260MM

|

|

Maximum stroke

|

160MM

|

|

Weight

|

1200KG

|

|

|

|

Working process:

This machine is the main structure of fixed mold under the rotary worktable, fixed slide carrige of wheel motor, linear guide,manual/electric screw, electric screw adopts gear motor to control the slide carrige up and down quicky . Its working process is: fixed mould on the worktable, electric quickly,manual slowly, to adjusting -tool.According to the hand wheel dial through the screw on the linear guide to realize the g rinding amount of rthe grinding machine.

This machine is the main structure of fixed mold under the rotary worktable, fixed slide carrige of wheel motor, linear guide,manual/electric screw, electric screw adopts gear motor to control the slide carrige up and down quicky . Its working process is: fixed mould on the worktable, electric quickly,manual slowly, to adjusting -tool.According to the hand wheel dial through the screw on the linear guide to realize the g rinding amount of rthe grinding machine.

Application

Our gringding machine can used to grind the die of these brand ,such as Amada,Muratec,Trumpf,Tailift.

And also can be used for punches,concave mould and shearing mould.

Company Introduction

Maanshan WILA CNC Machine Tools CO.,LTD

Our company specializes in R&D and production of various machine.Such as grinding machine ,press brake,shearing machine,punching machine and so on.All series machines are with two year's warranty.Also our service support various languages,like English,Spanish,Russian,and so on. Meanwhile,customized equipment are available according

to different requirements.

With our hardworking ,WILA CNC has passed CE and FDA qualifications.Which assures high-efficient production and products' reliability. Now WILA's products have presented in more than 100 countries such as North America,West Europe,South Asia,South America and Mid East etc...

to different requirements.

With our hardworking ,WILA CNC has passed CE and FDA qualifications.Which assures high-efficient production and products' reliability. Now WILA's products have presented in more than 100 countries such as North America,West Europe,South Asia,South America and Mid East etc...

Our Exhibition

Contact us

How to contact us

Maanshan WILA CNC Machine Tools CO.,LTD

Maanshan WILA CNC Machine Tools CO.,LTD

E-MAIL:sales2@

wilacnc.com

Mobile phone: +86 15255506339(same as wechat)

Web: http://wila.en.alibaba.com

Mobile phone: +86 15255506339(same as wechat)

Web: http://wila.en.alibaba.com

FAQ

1,

Q: Min. Order Quantity?

A: 1 set is OK.

2, Q: Do you have training?

A: 1 set is OK.

2, Q: Do you have training?

A: Of course.On line or fece to face.

3, Q: What's our warranty?

A: 2 years.

4, Q: Ways of payment?

A: T/T, L/C, D/P .Depend on you.

5, Q: Ways of shipment?

A: EXW, FOB, CIF,by Air/Sea , upon your requirements.

6, Q: How about your technical team construction?

A: We have professional technicians team with 15 years' experience.

7, Q: Can you accept OEM or ODM?

A: Of course,Logo is also acceptable.

8, Q: What is the delivery time?

A: For general specification model, it can be delivered within 15 days;

For customized models, delivery time shall be discussed and confirmed according to order.

3, Q: What's our warranty?

A: 2 years.

4, Q: Ways of payment?

A: T/T, L/C, D/P .Depend on you.

5, Q: Ways of shipment?

A: EXW, FOB, CIF,by Air/Sea , upon your requirements.

6, Q: How about your technical team construction?

A: We have professional technicians team with 15 years' experience.

7, Q: Can you accept OEM or ODM?

A: Of course,Logo is also acceptable.

8, Q: What is the delivery time?

A: For general specification model, it can be delivered within 15 days;

For customized models, delivery time shall be discussed and confirmed according to order.

Hot Searches