Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Tolerance:

-

±5%

-

Steel Grade:

-

316, L1, 304, 201

-

Surface Finish:

-

pvd

-

Length:

-

customized

-

Width:

-

customized

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

grand metal

-

Model Number:

-

201 304 316

-

Application:

-

wall decoration

-

Product name:

-

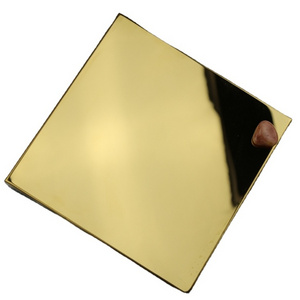

PVD Color Stainless Steel Sheet

-

Surface:

-

pvd

-

Color:

-

Customers Samples Color

-

Price Term:

-

CIF CFR FOB EX-WORK

-

Edge:

-

Mill Edge Slit Edge

-

Technique:

-

Cold Rolled.hot Rolled

-

Pvc:

-

3C/5C/7C/8C/10C/Laser

-

Payment Term:

-

30%T/T Advance + 70% Balance

-

Certification:

-

ISO

Quick Details

-

Grade:

-

300 Series

-

Standard:

-

JIS

-

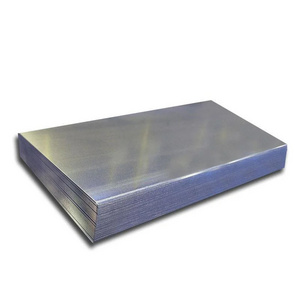

Thickness:

-

0.3-3.0mm

-

Tolerance:

-

±5%

-

Steel Grade:

-

316, L1, 304, 201

-

Surface Finish:

-

pvd

-

Length:

-

customized

-

Width:

-

customized

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

grand metal

-

Model Number:

-

201 304 316

-

Application:

-

wall decoration

-

Product name:

-

PVD Color Stainless Steel Sheet

-

Surface:

-

pvd

-

Color:

-

Customers Samples Color

-

Price Term:

-

CIF CFR FOB EX-WORK

-

Edge:

-

Mill Edge Slit Edge

-

Technique:

-

Cold Rolled.hot Rolled

-

Pvc:

-

3C/5C/7C/8C/10C/Laser

-

Payment Term:

-

30%T/T Advance + 70% Balance

-

Certification:

-

ISO

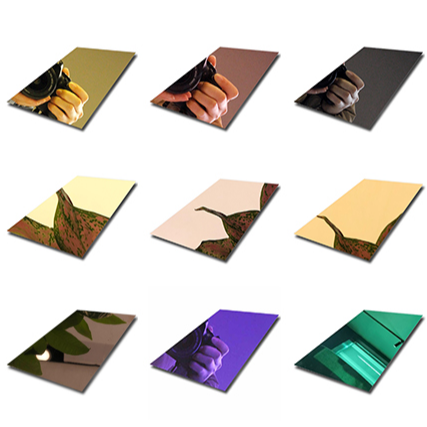

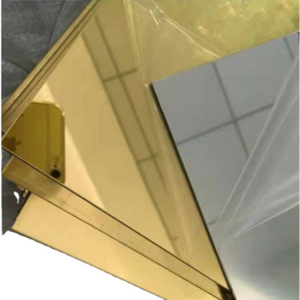

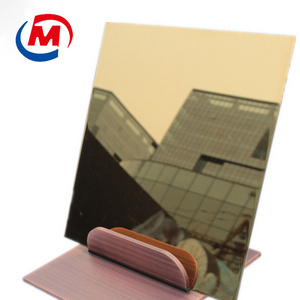

Mirror Stainless Steel Sheet

Mirror finish stainless steel sheet is also named mirror-polished stainless steel sheet, which is processed with a non-directional

and high-gloss polished #8 finish to remove the scratches, grooves, or dents on the surface, which can make it like a super

reflective mirror, and it doesn’t need any finishing or coating material to assist the process. As mirror stainless steel sheet

features mirror properties such as high reflectivity, brightness, and high shine, which can create a visually aesthetic and

appealing effect, so it’s perfectly ideal to be used for applications in architecture and interior ornament. At TBK Metal, we

generally use both 304 and 316 grades of stainless steel sheets as the basic material to polish, you can have an option to fit

your specified needs, all of them have durability and strength to provide longevity.

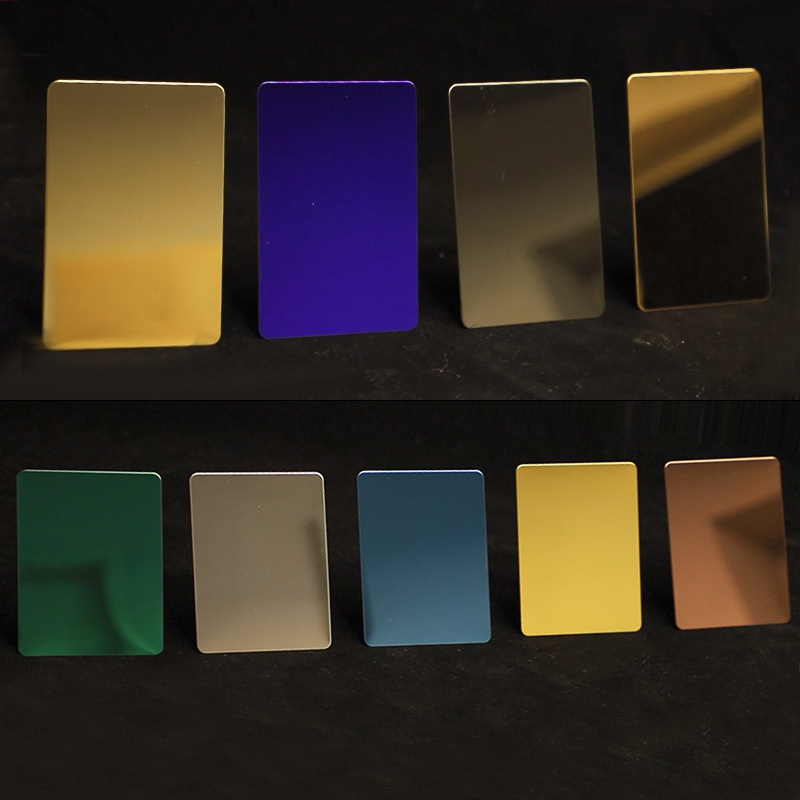

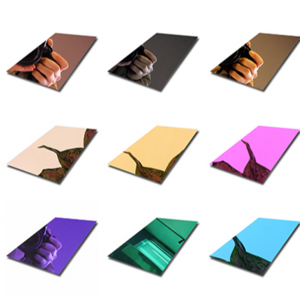

There is a wide range of color options for mirror finish stainless sheets, which can provide different visual effects for different requirements.All of them can improve your project with valuable properties, such as appealing aesthetics, resistance to rust and corrosion, longevity, and so on. The surface of mirror stainless steel sheets is finished with BA, 2B polish also known as #8, it comes with high gloss and reflectivity to bring the interior or exterior space a unique visual experience.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Material :

|

stainless steel

|

MOQ :

|

1 sheets

|

|

Tolerance:

|

|

|

|

|

|

|

|

|

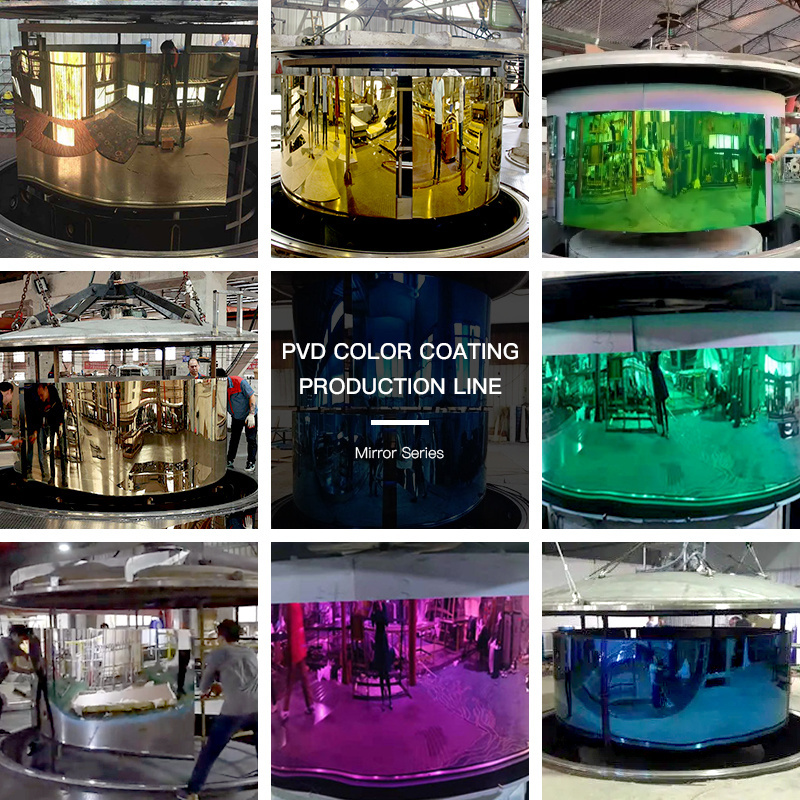

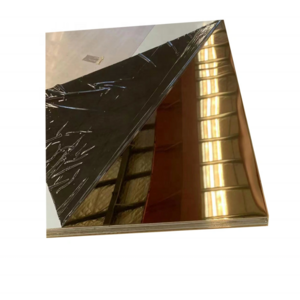

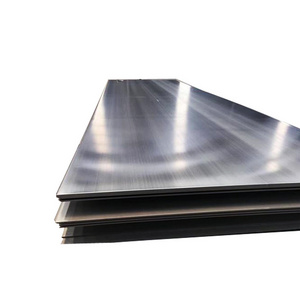

stainless steel 2B plate is the base material for 8 mirror polishing, with abrasives on the grinding tools and red powder or grinding agents being one of the most frequently employed abrasives. Grinding out a piece of standard 2B steel into a mirror is challenging, so at Vigor, we coat each piece with PVC protective film toward your shine.

Mirror-finished stainless steel sheets form a beautiful, reflective surface that functions as a mirror, ln addition. mirror finish can be easily combined with PVD color coating for a unique, reflective wall, ceiling, or accessory.

1.

Strong gloss

: Because of the mirror effect, the decorative panel is more beautiful and bright;

2.

Strong stain resistance

: The surface is very smooth and not easily contaminated with dust, easy to clean and maintain;

3. Good scratch resistance : Can withstand strong impact and scratches;

4. Good wear resistance : It is more wear-resistant than ordinary steel plates and has a long service life;

5. Good high temperature resistance : It can be used normally without deformation under the high temperature of 300 degrees Celsius.

6. Good environmental performance (recyclable) : Comply with ROHS standard.

7. Good process performance (can do various complex shapes)

8. There are many kinds of colors

3. Good scratch resistance : Can withstand strong impact and scratches;

4. Good wear resistance : It is more wear-resistant than ordinary steel plates and has a long service life;

5. Good high temperature resistance : It can be used normally without deformation under the high temperature of 300 degrees Celsius.

6. Good environmental performance (recyclable) : Comply with ROHS standard.

7. Good process performance (can do various complex shapes)

8. There are many kinds of colors

The production process of an 8k mirror stainless steel plate involves several steps. Here is a general overview of the process:

1. Material Selection : High-quality stainless steel is chosen as the base material for the plate. Stainless steel alloys such as 304 or 316 are commonly used due to their corrosion resistance and aesthetic appeal. 2. Surface Cleaning : The stainless steel plate is thoroughly cleaned to remove any dirt, oil, or contaminants.This can be done through various methods such as chemical cleaning, mechanical cleaning, or a combination of both.

3. Grinding : The plate undergoes a grinding process to remove any surface imperfections, scratches, or irregularities. Initially, coarse grinding wheels are used to remove larger imperfections, followed by progressively finer grinding wheels to achieve a smoother surface.

4. Polishing : After grinding, the plate goes through a series of polishing steps to achieve a high level of smoothness. Different abrasive materials, such as polishing belts or pads, are used to gradually refine the surface. The process typically involves multiple stages of polishing, starting with coarser abrasives and progressing to finer ones.

5. Buffing : Once the desired level of smoothness is achieved through polishing, the plate undergoes buffing. Buffing involves the use of a soft cloth or pad along with a polishing compound to further enhance the surface finish and remove any residual imperfections.

6. Cleaning and Inspection : The plate is thoroughly cleaned again to remove any polishing residues or contaminants. It is then inspected for defects, such as scratches, dents, or blemishes, to ensure it meets the required quality standards.

7. Electroplating (Optional) : In some cases, an additional electroplating process may be employed to enhance the mirror-like appearance and durability of the stainless steel plate. This process involves the deposition of a thin layer of metal, typically chromium or nickel, onto the surface of the plate.

8. Final Inspection and Packaging : The finished 8k mirror stainless steel plate undergoes a final inspection to ensure it meets all specifications and quality requirements. It is then carefully packaged to protect it during transportation and storage.

1. Material Selection : High-quality stainless steel is chosen as the base material for the plate. Stainless steel alloys such as 304 or 316 are commonly used due to their corrosion resistance and aesthetic appeal. 2. Surface Cleaning : The stainless steel plate is thoroughly cleaned to remove any dirt, oil, or contaminants.This can be done through various methods such as chemical cleaning, mechanical cleaning, or a combination of both.

3. Grinding : The plate undergoes a grinding process to remove any surface imperfections, scratches, or irregularities. Initially, coarse grinding wheels are used to remove larger imperfections, followed by progressively finer grinding wheels to achieve a smoother surface.

4. Polishing : After grinding, the plate goes through a series of polishing steps to achieve a high level of smoothness. Different abrasive materials, such as polishing belts or pads, are used to gradually refine the surface. The process typically involves multiple stages of polishing, starting with coarser abrasives and progressing to finer ones.

5. Buffing : Once the desired level of smoothness is achieved through polishing, the plate undergoes buffing. Buffing involves the use of a soft cloth or pad along with a polishing compound to further enhance the surface finish and remove any residual imperfections.

6. Cleaning and Inspection : The plate is thoroughly cleaned again to remove any polishing residues or contaminants. It is then inspected for defects, such as scratches, dents, or blemishes, to ensure it meets the required quality standards.

7. Electroplating (Optional) : In some cases, an additional electroplating process may be employed to enhance the mirror-like appearance and durability of the stainless steel plate. This process involves the deposition of a thin layer of metal, typically chromium or nickel, onto the surface of the plate.

8. Final Inspection and Packaging : The finished 8k mirror stainless steel plate undergoes a final inspection to ensure it meets all specifications and quality requirements. It is then carefully packaged to protect it during transportation and storage.

FAQ

Q1.About us,the relation between factory,manufacture or trader?

A1. Grand metal is a professional production of coldrolled stainless steel conglomerate , with professional production of stainless steel experience and our own factory nearly 12 years,where has more than 1,000 professional and technical workers. we are the foreign trade department of

Grand metal

. All our goods are dispatched directly from

Grand metal

mill.

Q2.What are

Grand'

s main products?

A2.

Grand

’s main products include 201/304 stainless steel coil and sheets,decorative stainless steel sheet, decorative stainlesssteel tile trim all different styles of etched and embossed,surface finished will be customized.

Q3.How can you ensure the quality of your product?

A3.All products have to go through three checks in the whole manufacturing process, it includes production,cutting sheets and the packing.

Q4.What is your delivery time and the supply ability?

A4.The delivery time normally within 15~20working days,we can supply about 15,000tons every month.

Q5.What kind of equipment in your factory?

A5.Our factory have advanced five-eighth roller rolling,cold rolling production equipment on the roll, advanced processing and testing equipment,which makes our product better quality with efficiency.

Q6.About the complaint,quality problem,etc aftersales service,how do you handle it?

A6.We will have certain colleague to follow our order accordingly for each order with professional after-sales service. If any claim happen, we will take our responsibility and compensate as per contract. For better serve our client, we'll keep tracing feedback of our products from clients and that's what make us different from other suppliers. We're customer care enterprise.

Q7.As the first customer,how do we trust you?

A7.On the top of page,you can see a line of credit with $228,000. It provides our company with higher degrees of credibility in the alibaba.We can guarantee the safety of your order.

Hot Searches