- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SIWAY

-

Model Number:

-

SikaFlex 265

-

Type:

-

SikaFlex

-

Color:

-

black,white,grey

-

Application:

-

metal

-

Product name:

-

polyurethane sealant

-

Appearance:

-

sealant

-

Shelf life:

-

12 Months

-

Package:

-

sausage

-

Keywords:

-

polyurethane sealant

-

Viscosity:

-

Strong

-

Volume:

-

600ml

-

Quality:

-

Guarantee

Quick Details

-

CAS No.:

-

61788-97-4

-

Other Names:

-

Silicone Sealant

-

MF:

-

C6H7NO2

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SIWAY

-

Model Number:

-

SikaFlex 265

-

Type:

-

SikaFlex

-

Color:

-

black,white,grey

-

Application:

-

metal

-

Product name:

-

polyurethane sealant

-

Appearance:

-

sealant

-

Shelf life:

-

12 Months

-

Package:

-

sausage

-

Keywords:

-

polyurethane sealant

-

Viscosity:

-

Strong

-

Volume:

-

600ml

-

Quality:

-

Guarantee

Product description

|

Product Name

|

SikaFlex 265

|

|

scope of application

|

Wood, metal, ceramics, plastic.

|

|

Base material

|

polyurethane sealant

|

|

volume

|

600ml

|

|

clour

|

black

|

|

shelf life

|

12 months after production date

|

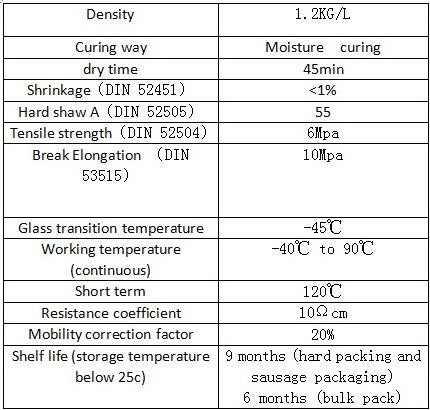

Features

Single component polyurethane sealant.

Single component composition, low volatile odor, outstanding construction characteristics.

Fast curing, aging resistance and weathering.

Curing forms a permanent elastic substance.

Anti - uv, especially suitable for exposed seam filling.

Single component composition, low volatile odor, outstanding construction characteristics.

Fast curing, aging resistance and weathering.

Curing forms a permanent elastic substance.

Anti - uv, especially suitable for exposed seam filling.

The product description

1. The sika Sikaflex265 polyurethane adhesive is a single group of polyurethane window glass adhesive which is flexible and can be filled after curing.

2. Sikaflex-265 is the window glass glue made in strict accordance with ISO9001/14001 quality assurance system.

3. Sica Sikaflex265 window glass adhesive agent is the window glass bonding for OEM and maintenance market. Widely used in passenger cars, trucks and trains, applicable to all its made of inorganic glass window.

4. The west card 265 can be fully equipped with the tools to obtain the excellent glue surface, and it has been specially designed to enhance its resistance to ultraviolet radiation, so it is especially suitable for exposed seam filling.

5. Chemical resistance:

It has resistance to fresh water, seawater, lime water, sewage flow, dilute acid and dilute alkali.

Temporary resistance to fuel oil, mineral oil, vegetable oil, animal fat and crude oil;

There is no resistance to organic acids, alcohol, concentrated mineral acids, concentrated bases and solvents.

The above instructions are only for general guidance, and we will advise on specific applications as required.

6. Surface preparation: the binding surface must be clean, dry and remove all kinds of grease and dust.

7. Do not work in an environment less than 10 degrees Celsius or above 35 degrees Celsius. The optimum temperature for the substrate and glue is 15 to 25 degrees Celsius.

1. The sika Sikaflex265 polyurethane adhesive is a single group of polyurethane window glass adhesive which is flexible and can be filled after curing.

2. Sikaflex-265 is the window glass glue made in strict accordance with ISO9001/14001 quality assurance system.

3. Sica Sikaflex265 window glass adhesive agent is the window glass bonding for OEM and maintenance market. Widely used in passenger cars, trucks and trains, applicable to all its made of inorganic glass window.

4. The west card 265 can be fully equipped with the tools to obtain the excellent glue surface, and it has been specially designed to enhance its resistance to ultraviolet radiation, so it is especially suitable for exposed seam filling.

5. Chemical resistance:

It has resistance to fresh water, seawater, lime water, sewage flow, dilute acid and dilute alkali.

Temporary resistance to fuel oil, mineral oil, vegetable oil, animal fat and crude oil;

There is no resistance to organic acids, alcohol, concentrated mineral acids, concentrated bases and solvents.

The above instructions are only for general guidance, and we will advise on specific applications as required.

6. Surface preparation: the binding surface must be clean, dry and remove all kinds of grease and dust.

7. Do not work in an environment less than 10 degrees Celsius or above 35 degrees Celsius. The optimum temperature for the substrate and glue is 15 to 25 degrees Celsius.

Applications

Applications

Wood, metal, ceramics, plastic.

Package

factory

Our client visit our factory

WELCOME TO VISIT US --- SIWAY

Big smile on Majesties face. Silicone sealant in your home, Money rushes to you.

More Professional, More Patient, More Responsibility.

Our Siway team always try our best to help all of you.

Similar Product

|

SV-666

|

NEUTRAL SILICONE SEALANT

|

|

SV-777

|

STONE SILICONE SEALANT

|

|

SV-888

|

WATERPROOF SILICONE SEALANT

|

|

SV-995

|

STRUCTURAL SILICONE SEALANT

|

Exhibition

Test&Certification

1.International sales service:

We have professional international sales team who can supply you service instantly.

2. Engineers:

Engineers with 15 years experience help you pick out the correct silicone sealant for certain project and material.

3. Quality Control :

Control the condition of each step in silicon sealant process

Supplier Assessment Certificate

ISO9001

UL

We have the most professional R&D team for our amazing Siway silicone sealant. Every step will be checked and tested again and again.

Hot Searches