- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

PaiXie

-

Dimension(L*W*H):

-

2200*1500*1800mm

-

Weight (KG):

-

350

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Chubby Gorilla Bottle Filling Line

-

Product advantage:

-

Can be customized/High precision/Space saving/Effective cost

-

Filling pump:

-

Peristaltic Pump Filling/Piston Pump Filling

-

Material:

-

SUS304/316(Meet GMP Standard)

-

Eligibility rate:

-

≥99%

-

Main motor:

-

Servo motor(ABB)

-

Machinery Capacity:

-

4000BPH, 8000BPH

-

Application:

-

Chemical, Machinery & Hardware, Cosmetics

Quick Details

-

Production Capacity:

-

80-200 BPH

-

Place of Origin:

-

Shanghai, China

-

Year:

-

2024

-

Brand Name:

-

PaiXie

-

Dimension(L*W*H):

-

2200*1500*1800mm

-

Weight (KG):

-

350

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Chubby Gorilla Bottle Filling Line

-

Product advantage:

-

Can be customized/High precision/Space saving/Effective cost

-

Filling pump:

-

Peristaltic Pump Filling/Piston Pump Filling

-

Material:

-

SUS304/316(Meet GMP Standard)

-

Eligibility rate:

-

≥99%

-

Main motor:

-

Servo motor(ABB)

-

Machinery Capacity:

-

4000BPH, 8000BPH

-

Application:

-

Chemical, Machinery & Hardware, Cosmetics

Product Description

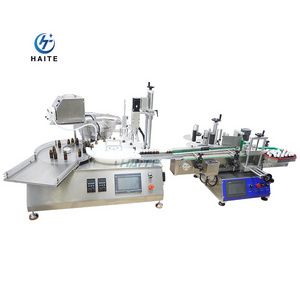

Automatic Plastic Bottle Chubby Gorilla Bottle Filling Line Chubby Gorilla Bottle Filling Line

1, The machine adopts the disc type unscrambling bottles, automatic feeding bottles

2, SIEMENS PLC control system, colored touch-screen display.

3, The pressure plug is automatic sorting this stoppers by the vibrating disk, automatic drop plug and plugging, Equipped with device of automatic induction pressure plug, so reliability is higher

4, The lock cover machine is also similar, it is automatic sorting by vibration plate, hanging cover and adopted the special lock head, three knife capping, lock port appearance is beautiful .

Technical Parameters

|

Product

|

Full Automatic 10/15/30/60/120/100 ml Chubby Gorilla bottle filling Capping Labeling Machine

|

|

Output

|

6000-16000BPH, or customized

|

|

Filling Volume

|

10-100ml, or customized

|

|

Air compressor

|

0.6-0.8Mpa

|

|

Filling Material

|

Nitroglycerin

|

|

Control

|

PLC and Touch Screen

|

|

Driving Motor

|

Servo Motor

|

|

Capping motor

|

Magnetic motor

|

|

Torque

|

0-100N

|

|

Detection

|

Photocell

|

|

Filling Type

|

Piston Pump, Peristaltic Pump

|

|

Power

|

1.5KW

|

|

Material

|

SS304

|

|

Capping Head

|

Screwing, Pressing, Crimping Head ( According to the cap type)

|

|

Suitable Industry

|

Cosmetic, food, detergent, etc

|

|

Human protection

|

Complete safety switch alarm

|

|

Cap type

|

Chubby Gorilla bottle

|

Application

Details Images

Frequency speed turntable is used to input bottle automatically

Variable speed rotary bottle feeding table is the basic feeding system of filling line, operator will put empty bottles on the table, with gear motor driving, the bottle will be arranged to smarter filler input interface correctly. With flexible output tunnel, the machine will be able to work with different size bottle.

Unscrambler is another good choice

Sometimes we run bottle unscramber , especially for 10 ml gorilla , due to heavy low weight , 10 ml gorilla can not stand well on the table , we invent unscrambler , you just put bottle inside , then it arrange bottle direction and output into filling machine automatically .Different size botle with different molds , it works with many different formats gorilla , of course , the bigger the bigger .

How to work with so many different size gorilla ? Especially when you run 10-120 ml

10ml gorilla unscrambler

15/30/60 ml gorilla unscrambler

120/200ml gorilla unscrambler

Combination of the unscrambler and feeding table

To save budget cost , most customer select to run 10 ml with unscrambler , others are feed by rotary table .

How to ensure fast filling speed and high precision ?

SUS316L Piston pumps+Filling nozzles

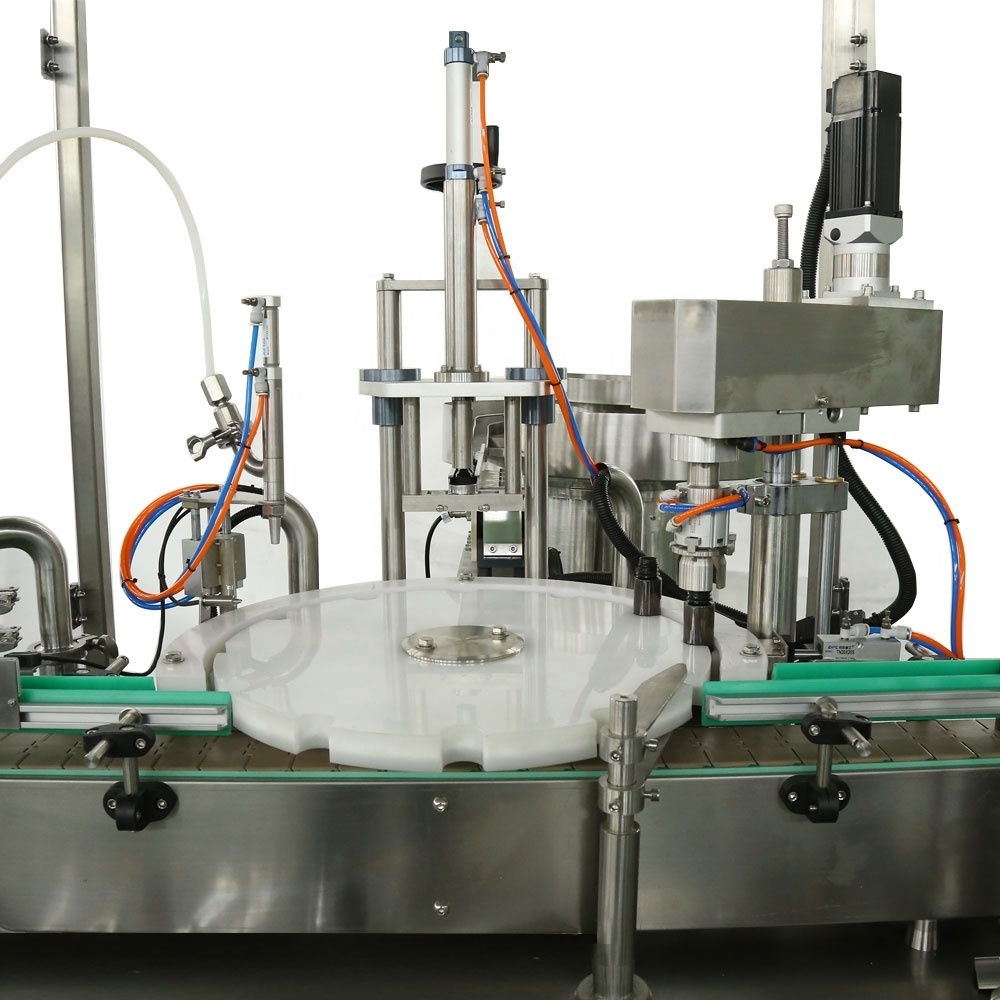

This is wheel type piston pump filling machine which is designed for small bottle and low capacity filling task, driven by servo motor with high precision. The filling nozzles are made of SS316, resist high temperature filling. drip-proof , via photoelectric detection to ensure no bottle no filling.

Servo motor driving

Different from traditional air driving , paixie customize machine by servo motor , it is contributed to precision control and different volume change ,everything will be done by HMI adjustment

Servo filling station construction

1- High precison , we control the servo motor by PLC , the servo contected with the piston pump by screw , the motor running up ,push the screw , then screw push piston at the opposite , so actually the filling volume is equal to motor running distance .

How to have the cap to be inserted accurately ?

Cap vibrator

With the customzied mold , all format spray can be inserted into bottle accurately

Cap inserting station with mold

With the customzied mold ,all formats dropper can be inserted into the bottle accurately

Vibrator construction

By replace the top hopper , we are able to work with different caps

How to Ensure the capping torque and protect from broken ?

Three-jar capping head application

The three-Jaw capping head is the newest design for different cap size , it is easy adjusted .

Magnetic cap torquing motor

To be different from traditional capping motor , Paixie uses magnetic motor in torquing , you can set all power as the cap need so that we prevent cap from broken or liquid leaking beucase of toure over or few

How to replace bottle from one format to another format ?

We do bottle star wheel for each size bottle , that is the only part you have to replace , one bottle one wheel .

There is always a collecting table at the end of the packing line to collect all your gorillas .

More Recommendations

Facilities can utilize a completely customized configuration of filling machinery, with many size and shape options to meet space requirements. Each piece of equipment can work cohesively to keep operations smooth, allowing you to get the results you want from your production line. Our equipment is constructed with high-quality materials that can avoid wear through long periods of heavy use, requiring less frequent maintenance than other machines of inferior quality. We can help you design a custom liquid filling system that works best in your facility.

Hot Searches