- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

240-300Grains/Min

-

Weight (KG):

-

1600

-

Voltage:

-

380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Harvest

-

Dimension(L*W*H):

-

3000X1300X1420mm

-

Product name:

-

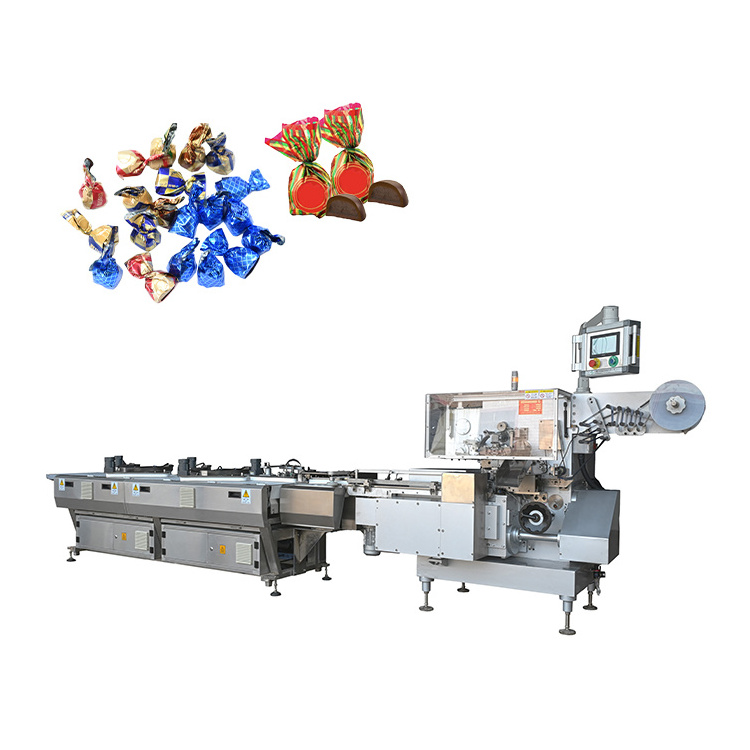

machine for wrapping small chocolates in paper

-

Packing speed:

-

240-300 Grains/Min

-

After Warranty Service:

-

Spare parts

-

After-sales Service Provided:

-

Online Support

-

Bleed Pressure:

-

0.6MPa

-

Packing Material:

-

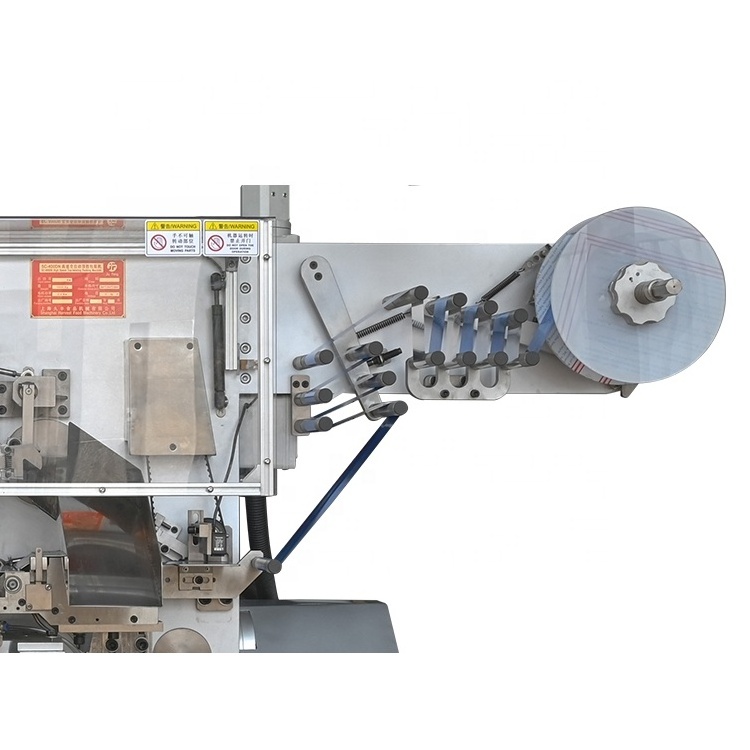

Kink packaging film PET

Quick Details

-

Function:

-

Wrapping, Sealing, Chocolate packing plant

-

Packaging Type:

-

Film, Foil

-

Packaging Material:

-

Kink packaging film PET

-

Production Capacity:

-

240-300Grains/Min

-

Weight (KG):

-

1600

-

Voltage:

-

380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Harvest

-

Dimension(L*W*H):

-

3000X1300X1420mm

-

Product name:

-

machine for wrapping small chocolates in paper

-

Packing speed:

-

240-300 Grains/Min

-

After Warranty Service:

-

Spare parts

-

After-sales Service Provided:

-

Online Support

-

Bleed Pressure:

-

0.6MPa

-

Packing Material:

-

Kink packaging film PET

Details Images

Product Paramenters

|

Product Name

|

packaging machine

|

|

Capacity

|

240- 300 Grains/Min

|

|

Product Size

|

(15~55) x (5~35) x (4~25) mm (length x width x height)

|

|

Packing Material

|

Kink packaging film PET

|

|

Size of bobbin core

|

73-75 mm

|

|

Power and Voltage

|

5.5Kw/380V/3P

|

|

Dimensions

|

(15~55) x (5~35) x (4~25) (length x width x height)

|

|

Dimensions of Packing Machine

|

3000X1300X1420mm (length x width x height)

|

|

Dimensions of Feeding Machine

|

3000X850X800mm (length x width x height)

|

|

Net Weight of Packing Machine

|

1600kg

|

|

Net Weight of eeding Machine

|

700kg

|

|

Bleed Pressure

|

0.6MPa

|

Products Description

Function and Characteristics

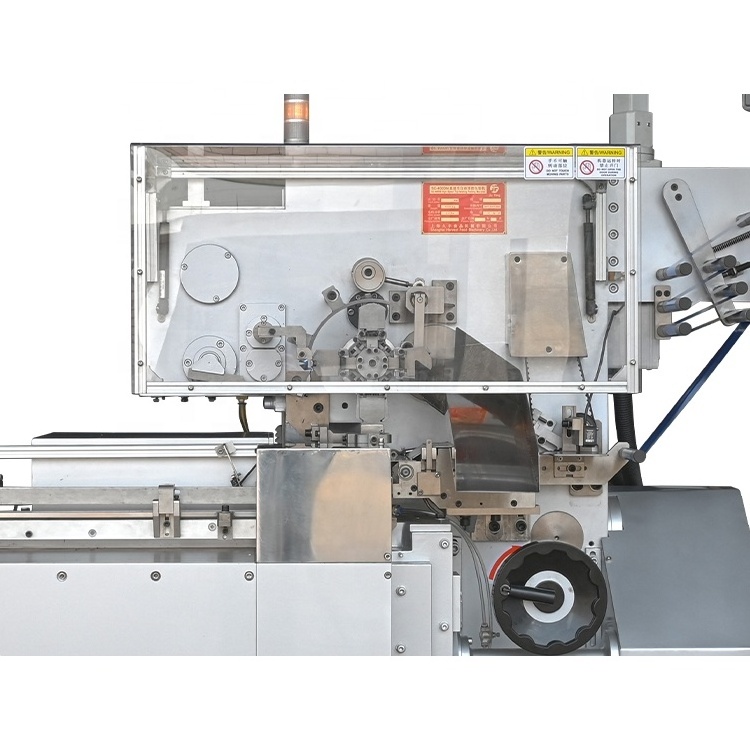

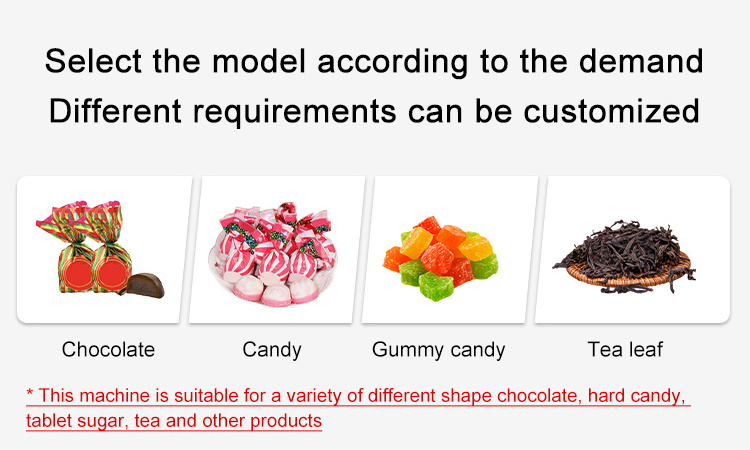

1. The machine is designed for allocating, feeding, and packing irregular shaped chocolates/hard candies/pressed sugar/tea automatically. It adopts the packing form of folding on the bottom and twisting on the top. SC-400DN ensures the packaging fits tightly and folding angels seem symmetrical and clear.

2. Accurate high-speed CAM mechanism and rational machinery design increase the precision, stability, and productivity of the machine.

3. Equipped with Panasonic Servo System, PLC (Programmable Logic Controller), multi-station sensor control system, the machine can supply double layer paper, correct the paper lengths, stop paper delivery with no sugar, position colorful trademarks and thus improve yields.

4. The Panasonic touch screen display in Chinese and English, achieves human computer interaction and provides easy way to operate such as set the parameters.

5. Equipped with high-speed automatic feeding transmission line, the machine can directly butt to casting machine and feeder machine, achieving fully automatic.

6. Automatic alarm for abnormality is designed for convenient use and easy maintenance.

Hot Searches