- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Darling Machinery

-

Voltage:

-

380V customized

-

Dimension(L*W*H):

-

12x1.8x2.1m

-

Weight (KG):

-

5500

-

Name:

-

CNC busbar processing line

-

Processing range:

-

12x160mm or 16x260mm

-

Processing method:

-

automatic for CNC busbar processing line

-

Punching type:

-

8 punching stations

-

Bending type:

-

electric mold for bending

-

Certification:

-

ISO9001 and CE CNC busbar processing line

-

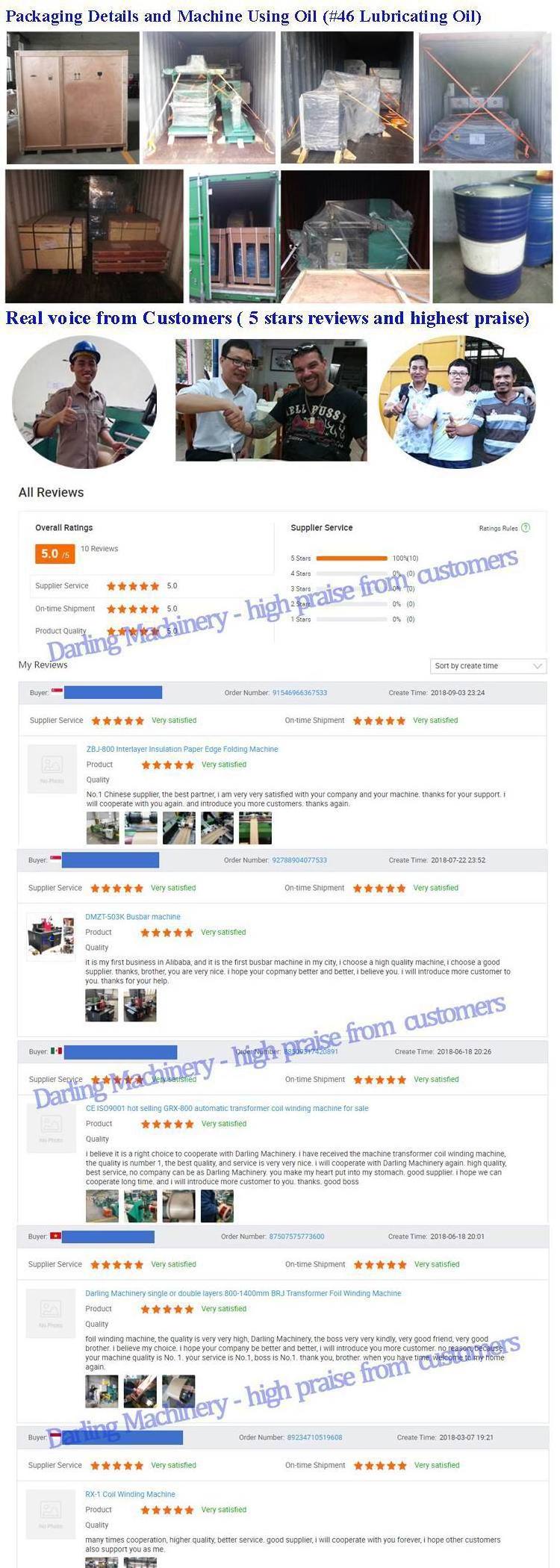

Package:

-

Fumigation-free Wooden Case

-

Delivery time:

-

30 Days CNC busbar processing line

Quick Details

-

Max. Thickness (mm):

-

12 mm

-

Max. Width (mm):

-

150 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Darling Machinery

-

Voltage:

-

380V customized

-

Dimension(L*W*H):

-

12x1.8x2.1m

-

Weight (KG):

-

5500

-

Name:

-

CNC busbar processing line

-

Processing range:

-

12x160mm or 16x260mm

-

Processing method:

-

automatic for CNC busbar processing line

-

Punching type:

-

8 punching stations

-

Bending type:

-

electric mold for bending

-

Certification:

-

ISO9001 and CE CNC busbar processing line

-

Package:

-

Fumigation-free Wooden Case

-

Delivery time:

-

30 Days CNC busbar processing line

factory sales DMLSX-303K copper CNC busbar processing line Busbar Machine

Watching machine working video directly ( Video link):

YouTube: https://youtu.be/GMmZ5Uevg-g

QQ video: https://v.qq.com/x/page/l3214fpb23x.html

Baidu video: https://haokan.baidu.com/v?vid=4310672068211310976&bfe=1

Machine model and specification

|

Punching |

Max power (KN) |

400 |

|

Punching Diameter (mm) |

Ø4.3~25 (copper and aluminum) |

|

|

Max thickness (mm) |

12 (copper and aluminum) |

|

|

Max width (mm) |

150 (copper and aluminum) |

|

|

Shearing |

Max power (KN) |

400 |

|

Max thickness (mm) |

12 (copper and aluminum) |

|

|

Max width (mm) |

150 (copper and aluminum) |

|

|

Bending |

Max thickness (mm) |

12 (copper and aluminum) |

|

Max width (mm) |

150 (copper and aluminum) |

|

|

Total power of Electric motor |

|

12KW |

|

Outline Dimensions(mm) |

|

8500L×1240W×1750H |

|

Weight |

T |

4.2 |

M ain Characteristics

1) This processing center is a special equipment used for copper or aluminum busbar processing in electric power, equipments for high and low voltage and busbar groove industry with characteristics of high efficiency, low consume, labor-saving, environmental, high accuracy, attractive in appearance, easy to operate and so on.

2) This center has original processing principle and method, which is completely different from the former conception of processing. It is adopted 4-axis control and 1-time clamping method. Work of punching, bending, shearing and so on can be finished without the aid of operator from rough material to finished work pieces, only clamping the banded pre-processing busbar to its right position for one time and matching with related programming operation. Work pieces are automatically finished and the waste is recycled completely.

3) This center adopts double pneumatic clamps, which achieves interactive accomplishment of automatic feeding without limiting the length of busbar with the location accuracy of ±0.1mm.

4) Punching unit takes 8-die turret punching method. Choosing die, locating and accurately controlling pitch of holes are finished automatically.

5) Adopting special bidirectional bending system to guarantee left-right bending finished one time. The precision of bending angle is controlled in ±0.5°. Shearing unit takes the method of punching. Work pieces surface is neat and smooth.

Our service

1, before sales: we will give you professional instruction and help you to buy the suitable machine, after you choose our machine, let you take the biggest profit through using our machine.

2, in sales: we will give you feedback informations about your order through photos and video. let you put your heart into stomach.

3, after sales: we will go to your factory to give you a training and teach you how to use our machine, or we will give you a video training. if there is our local agent and office, we will let our local engineer to your factory and give you a training.

4, our quality assurance: all our machine using life.

Getting Local office support, please contact with our company:

|

Shandong Darling Machinery Equipment Co., Ltd.

Add: Shacun Industry Park, Licheng District, Jinan City, China. Contact person: Martin Hoo +86-15253156158 (WhatsApp) Skype/Wechat: martinhoo936 QQ: 613252158 Website: www.darlingmachinery.com |

We will be the best partner

Although we live in different countries, our hearts are always together . We don ’ t only sell machine, we also sell service, technology and brand. One time cooperation, be friend forever!

Our cooperation is Double win results.

® Our aim is:

Through using our machine, you can make better product and earn more money !

FAQ:

1, are you manufacture or trading company?

we are manufacture more than 15 years, 3 branch factory, more than 10000 square meters.

2, how about your quality ?

we only sell high quality machine, we use the world famous brand component, like SIEMENS, MITSUBISHI, DELEM, PANASONIC, SCHNEIDER, ABB, etc. so there is no worry about our quality.

3, what about your after sales service ?

we go to your factory for site training or you can get local branch company traning, if there is no requirement, we can give you video training in other methods.

4, why do we must choose you as our supplier ?

customer real voice is your best reference, 5 stars customer feedback reviews, 100% high praise. those voice can let you to cooperate with us safely.