- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.1%

-

CrO Content (%):

-

0

-

SiC Content (%):

-

0

-

Place of Origin:

-

Shanxi, China

-

Applicable use:

-

Tunnel kiln, roller kiln, shuttle kiln, etc

-

product name:

-

Light quality does not come stone bricks

-

pigment:

-

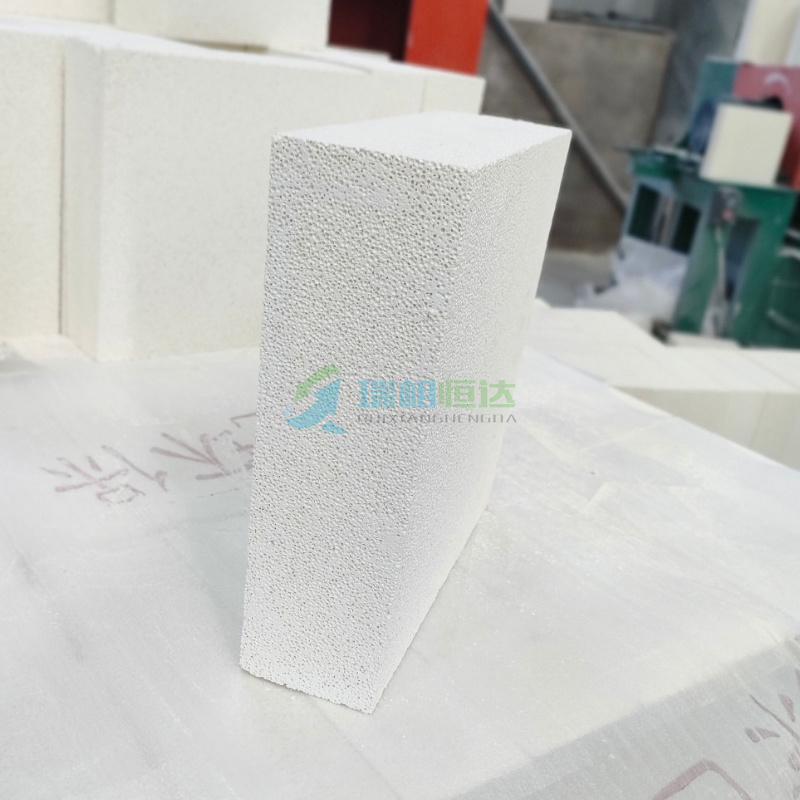

white

Quick Details

-

SiO2 Content (%):

-

50%~65%

-

Al2O3 Content (%):

-

35-48%

-

MgO Content (%):

-

0.5%

-

CaO Content (%):

-

0.1%

-

CrO Content (%):

-

0

-

SiC Content (%):

-

0

-

Place of Origin:

-

Shanxi, China

-

Applicable use:

-

Tunnel kiln, roller kiln, shuttle kiln, etc

-

product name:

-

Light quality does not come stone bricks

-

pigment:

-

white

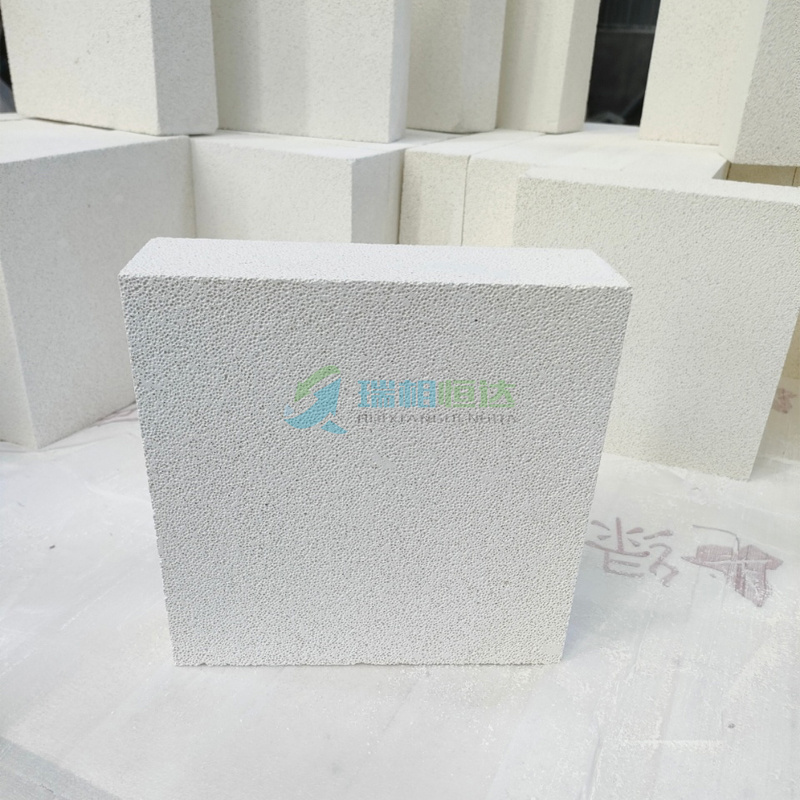

Ruixiang mullite bricks are made of high-quality and high-purity refractory powder, according to the specific gravity of the product, adding organic composite filler, and preparing lightweight mullite products by vacuum extrusion molding and high-temperature sintering finishing.

Product Features:

Low heat capacity, low thermal conductivity;

High purity and low impurity content;

High temperature resistance, direct contact with flame;

High strength, excellent high-temperature volume stability;

The size is precise and can be cut arbitrarily.

Typical Applications

It is suitable for various industrial furnace hot surface linings and backings in metallurgy, petrochemical, building materials, ceramics, machinery and other industries. Such as: cracking furnace, conversion furnace, heating device, refining device, regeneration device, hot blast furnace, heating furnace, soaking furnace, heat treatment furnace, resistance furnace, tunnel kiln, roller kiln, shuttle kiln, bell kiln, glass pool kiln, etc.

physicochemical indexes

|

GRADE 23 BRICK |

GRADE 26A BRICK |

GRADE 26B BRICK |

GRADE 28 BRICK |

GRADE 30 BRICK |

|

|

Classification Temperature (℃ ) |

1230 |

1350 |

1400 |

1500 |

1550 |

|

Chemical Composition (%) |

|||||

|

Al2O3 |

42 |

52 |

55 |

63 |

73 |

|

SiO2 |

51 |

41 |

41 |

31 |

24 |

|

Fe2O3 |

≤ 1.0 |

≤ 0.8 |

≤ 0.8 |

≤ 0.7 |

≤ 0.6 |

|

Density (kg/m³) |

600 |

800 |

800 |

900 |

1000 |

|

Modulus of Rupture (MPa) |

0.9 |

1.5 |

1.5 |

1.8 |

2.0 |

|

Cold Crushing Strength (MPa) |

1.5 |

2.5 |

2.5 |

2.6 |

3.0 |

|

Permanent Linear Change (%) |

1230 ℃ x 12hr - 0.5~0.5 |

1400 ℃ x 12hr - 0.5~0.5 |

1400 ℃ x 24hr - 1.0~0.5 |

1500 ℃ x 12hr - 1.0~0.5 |

1620 ℃ x 12hr - 0.5~0.5 |

|

Thermal Conductivity (W/m·K) |

|||||

|

350 ℃ |

0.18 |

0.25 |

0.25 |

0.33 |

0.38 |

letter of patent

Detection capacity and facilities

Wood tray packaging, upper and lower cardboard each layer of foam paper, winding film not less than three layers of plastic film to complete the overall packaging.

Can be packaged according to the Demander's requirements or on the drawings.

Transport: by boat or by train, samples can be delivered by international express.