- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V50HZ

-

Power:

-

7.5KW

-

Dimension(L*W*H):

-

6000*2500*1800 mm

-

Weight:

-

2800 kg

-

Product name:

-

Toilet paper machine

-

Capacity:

-

2 t/day

-

Raw Material:

-

Jumbo Roll Toilet Paper

-

Final Product:

-

Toilet tissue rolls, kitchen towel

-

Embossing:

-

Steel roller to wool roller

-

Working Speed:

-

30-50 m/min

-

Base Diameter:

-

<1200mm

-

Back Stand:

-

1-4ply

-

Perforation Pitch:

-

80-220mm, 150-300mm

-

After-sales Service Provided:

-

Online support

Quick Details

-

Production Capacity:

-

90 pcs/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Superb

-

Voltage:

-

380V50HZ

-

Power:

-

7.5KW

-

Dimension(L*W*H):

-

6000*2500*1800 mm

-

Weight:

-

2800 kg

-

Product name:

-

Toilet paper machine

-

Capacity:

-

2 t/day

-

Raw Material:

-

Jumbo Roll Toilet Paper

-

Final Product:

-

Toilet tissue rolls, kitchen towel

-

Embossing:

-

Steel roller to wool roller

-

Working Speed:

-

30-50 m/min

-

Base Diameter:

-

<1200mm

-

Back Stand:

-

1-4ply

-

Perforation Pitch:

-

80-220mm, 150-300mm

-

After-sales Service Provided:

-

Online support

Product Description

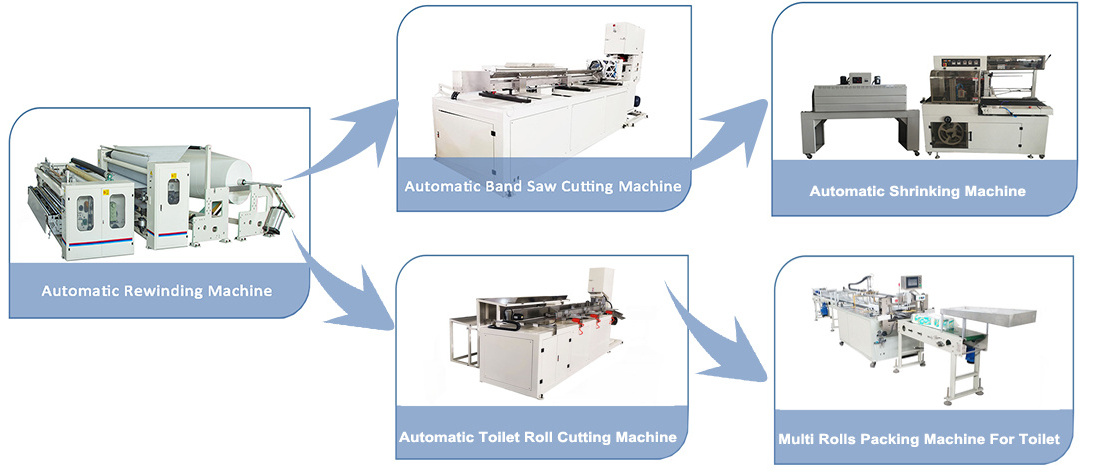

full automatic plant of kitchen toilet paper roll paper making packing machine

Automatic toilet paper rewinding machine is used for producing toilet paper roll and kitchen tower, it adopts the new PLC computer programming technology, frequency control, automatic electronic brake. Supporting touch human-machine interface operating system. The coreless and core paper rewinding molding system can be customized, embossing rolls pattern also can be customized.

Performance Characteristics

1. Application of PLC wind column forming technology reached the rewinding faster, the molding is beautiful, and so on. The application of PLC in automatic rewinding, automatically send the finished, immediately reset rewinding, automatic trimming, adhesive, sealing synchronously in one time. Sealing tail technology, convenient opening. To realize no paper loss, reducing the cost.

2. Application of raw paper monitoring system, paper breaking automatic stopping. High speed operation in the process of implementation, monitoring of the base paper, reduce loss off paper produced by the equipment, ensure the normal operation of high speed.

3. Automatic paper core dropping system and embossing system, it can produce toilet paper with both core and coreless, Reduce the labor cost, make the finished product more beautiful.

4. High precision screw perforated knife,3 scalpel lower noise, hole spacing adjustable, drilling more clear and beautiful. 4. Three layers synchronization conveying unwinder, pneumatic paper loading, each layer of base paper has the tension adjusting device.

5. Used in point switch traction base paper, paper leading the operation more simple, more safety.

2. Application of raw paper monitoring system, paper breaking automatic stopping. High speed operation in the process of implementation, monitoring of the base paper, reduce loss off paper produced by the equipment, ensure the normal operation of high speed.

3. Automatic paper core dropping system and embossing system, it can produce toilet paper with both core and coreless, Reduce the labor cost, make the finished product more beautiful.

4. High precision screw perforated knife,3 scalpel lower noise, hole spacing adjustable, drilling more clear and beautiful. 4. Three layers synchronization conveying unwinder, pneumatic paper loading, each layer of base paper has the tension adjusting device.

5. Used in point switch traction base paper, paper leading the operation more simple, more safety.

Machine Production Process

Details

Specification

|

Model

|

SB-R1092

|

SB-R1575

|

SB-R1880

|

SB-R2400

|

SB-R2800

|

SB-R3000

|

|||||

|

Raw paper diameter

|

1200 mm

|

1800mm

|

2200mm

|

2400mm

|

2800mm

|

3000mm

|

|||||

|

Raw paper weight

|

12-40 g/m2 toilet tissue paper jumbo roll

|

|

|

|

|

|

|||||

|

Raw paper width

|

less than 1200mm

|

|

|

|

|

|

|||||

|

Finished diameter

|

50-180mm

|

|

|

|

|

|

|||||

|

Finished paper core

|

Diameter 30-55 mm

|

|

|

|

|

|

|||||

|

Jumbo roll paper core

|

Diameter 76.2 mm

|

|

|

|

|

|

|||||

|

Parameter setting

|

PLC computer operating system interface,touch screen

|

|

|

|

|

|

|||||

|

Back stand

|

Three layers synchronous transmission

|

|

|

|

|

|

|||||

|

Perforation pitch

|

80-220mm,150-300mm

|

|

|

|

|

|

|||||

|

Embossing

|

Steel roll to woolen roll,single or double embossing

|

|

|

|

|

|

|||||

|

Paper loader

|

Automatic Pneumatic loading paper rolls

|

|

|

|

|

|

|||||

|

Paper core feeder

|

Automatic paper core dropping (core or coreless)

|

|

|

|

|

|

|||||

|

Total Power

|

4.5kw-10 kw

|

|

|

|

|

|

|||||

|

Production speed

|

150-280 m/min

|

|

|

|

|

|

|||||

|

Voltage

|

AC380V,50HZ

|

|

|

|

|

|

|||||

|

Air pressure

|

0.5Mpa

|

|

|

|

|

|

|||||

|

Dimensions

|

6200-7500)mm*(2600-3200)mm*1750mm

|

|

|

|

|

|

|||||

|

Weight

|

2500 kg-3800 kg

|

|

|

|

|

|

|||||

Packing & Delivery

FAQ

Q: Are you trading company or manufacturer?

A: We are manufacturer, some China trader cooperate with us, welcome to visit our factory, Trust you will like our service, quality and price

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could send free sample but customer should pay the freight cost.

Q: Why do we cooperate with Turui Machinery?

A: We are the only one company which can provide competitive advantage machine, and we promise to refund money to customer if delay the delivery.

Hot Searches