- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu,China

-

Brand Name:

-

LIANSHUN

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

45M*3M*2.5M

-

Power (kW):

-

250

-

Weight:

-

20000 KG

-

Inverter:

-

ABB Brand

-

Contactor:

-

Schneider Brand

-

Motor:

-

XIMA Brand

-

Temperature control:

-

Omron Brand

-

Final product:

-

PVC PIPE

-

Cooling way:

-

Water Cooling

-

Function:

-

Pvc Pipe Machine

-

Gear box:

-

Jiangyin

-

Product Type:

-

Extrusion Production

-

Name:

-

Pvc Pipe Production Line

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

132:1

-

Screw Speed (rpm):

-

120 rpm

-

Place of Origin:

-

Jiangsu,China

-

Brand Name:

-

LIANSHUN

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

45M*3M*2.5M

-

Power (kW):

-

250

-

Weight:

-

20000 KG

-

Inverter:

-

ABB Brand

-

Contactor:

-

Schneider Brand

-

Motor:

-

XIMA Brand

-

Temperature control:

-

Omron Brand

-

Final product:

-

PVC PIPE

-

Cooling way:

-

Water Cooling

-

Function:

-

Pvc Pipe Machine

-

Gear box:

-

Jiangyin

-

Product Type:

-

Extrusion Production

-

Name:

-

Pvc Pipe Production Line

Product Description

Description:

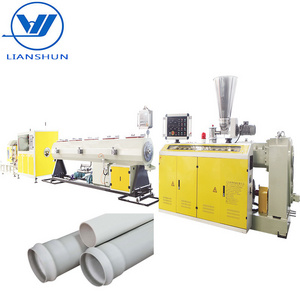

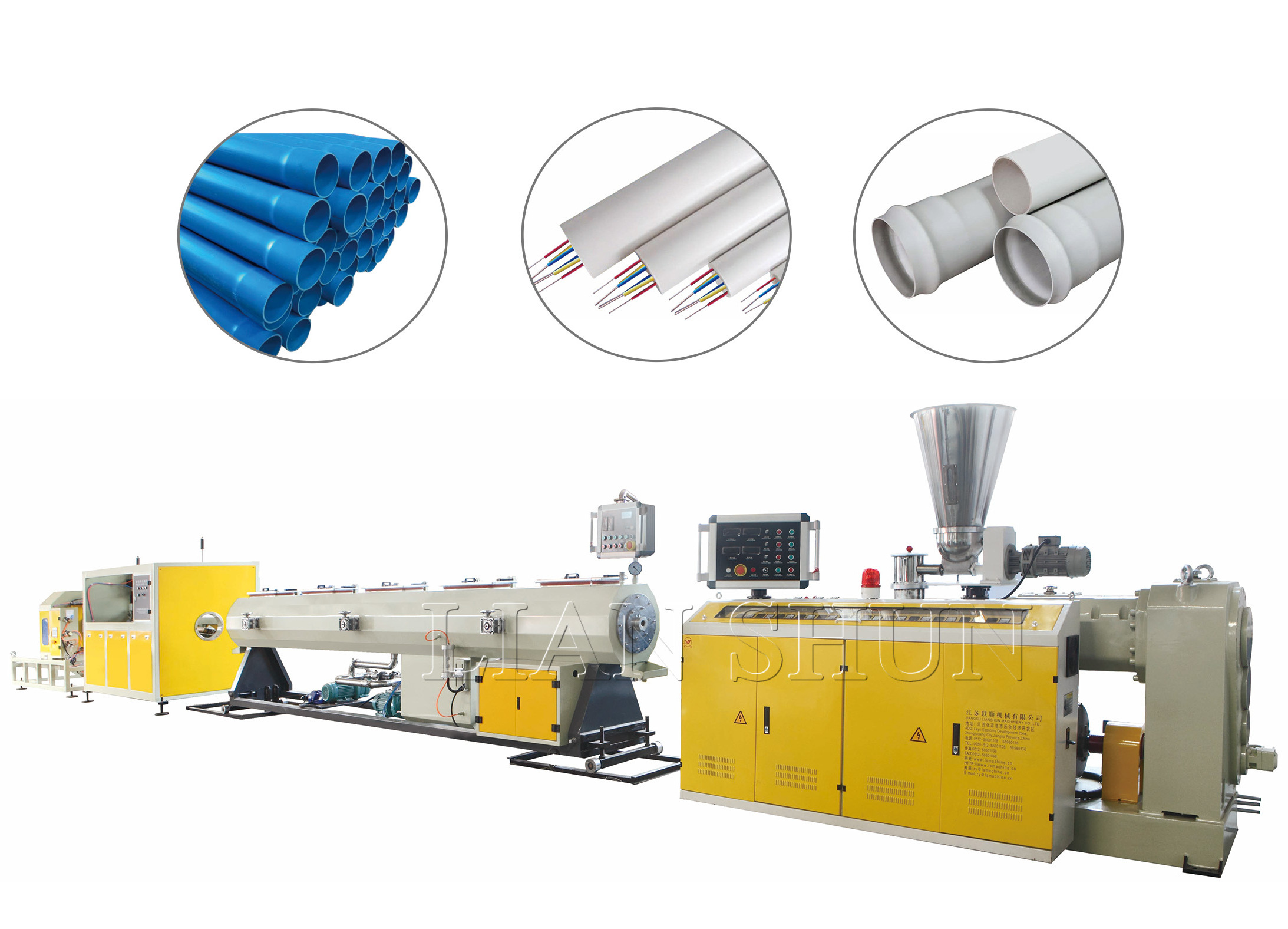

PVC pipe machine can process various soft and rigid PVC, especially process powder directly into pipe shape. PVC pipe production line machine consists pvc pipe extruder, vacuum calibration tank, haul-off unit, stacker or belling machine, etc. The pipe extruder machine and haul-off unit adopt AC inverters. PVC pipe extrusion line electric parts are international well-known brand products, which guarantee quality of machine. The PLC and big true-color screen panel make control system with high automation.

Process Flow:

Screw Loader for Mixer→ Mixer unit→ Screw Loader for Extruder→ Conical Twin Screw Extruder → Mold → Vacuum Calibration Tank →Haul-off machine→ Cutter machine→ Belling machine/ Tripping Table → Final Product Inspecting &Packing

Details Images

Conical Twin Screw Extruder

Both conical twin screw extruder and parallel twin screw extruder can be applied to produce PVC pipe. With latest technology, to lower power and ensure capacity. According to different formula, we provide different screw design to ensure good plasticizing effect and high capacity.

Extrusion Mold / Die Head

Extrusion die head apply spiral structure, each material flow channel is placed evenly. Each channel is after heat treatment and mirror polishing to ensure material flow smoothly. Die head structure is compact and also provide stable pressure, always from 19 to 20Mpa. Under this pressure, pipe quality is good and very little effect on the output capacity. Can produce single layer or multi-layer pipe.

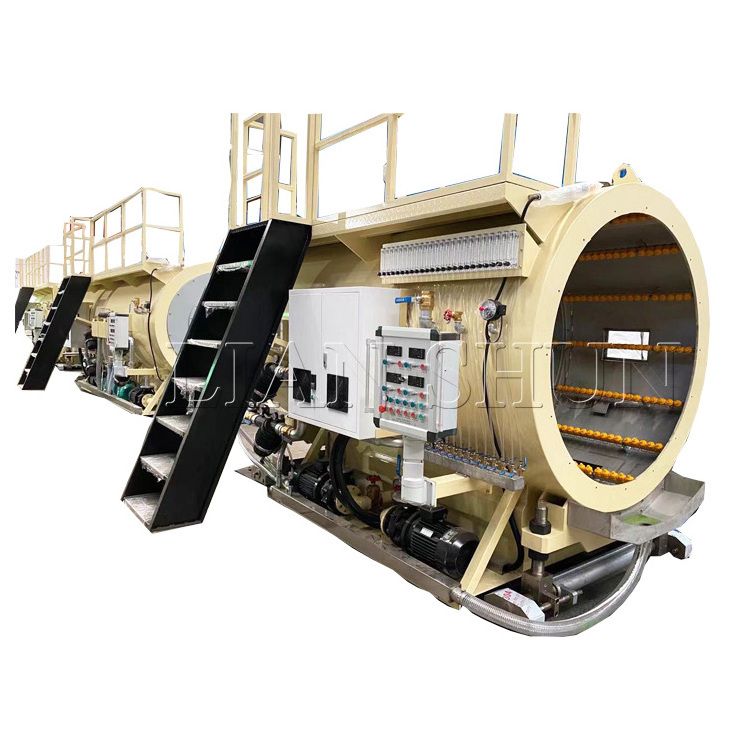

Vacuum Calibration Tank

Vacuum Calibration tank is used to shape and cool pipe, so as to reach standard pipe size. We use double-chamber structure. First chamber is in short length, to ensure very strong cooling and vacuum function. As calibrator is placed in the front of first chamber and pipe shape is formed mainly by calibrator, this design can ensure quick and better forming and cooling of pipe.

Haul Off machine

Haul off machine provides sufficient traction force to pull pipe stably. According to different pipe sizes and thickness, our company will customize traction speed, number of claws, effective traction length. To ensure match pipe extrusion speed and forming speed, also avoid deformation of pipe during traction.

PVC Pipe cutting machine

Pipe cutting machine also called pipe cutter machine controlled by Siemens PLC, working together with haul off unit to have precise cutting. Customer can set the length of pipe they want to cut. Multi-feed-in actions for the accomplishment of one cutting process(protect blades and saws, prevent from blade and saws stuck for thick pipe and cut face of pipe is smooth).

PVC pipe belling machine

To make socket at pipe end which is easy for pipe connection. There are three types of belling type: U type, R type and Square type. We provide belling machine which can finish belling of pipe on line fully automatic. From minimum size 16mm to maximum size 1000mm, can with multi heating oven and belling station.

Product Paramenters

|

Model

|

Pipe range (mm)

|

Extruder

|

Die Head

|

Extrusion power (kW)

|

Haul-off speed (m/min)

|

|

PVC-50 (Dual)

|

16-50

|

SJZ51/105

|

Double outlet

|

18.5

|

10

|

|

PVC-63 (Dual)

|

20-63

|

SJZ65/132

|

Double outlet

|

37

|

15

|

|

PVC-160

|

20-63

|

SJZ51/105

|

Single outlet

|

18.5

|

15

|

|

PVC-160

|

50-160

|

SJZ65/132

|

Single outlet

|

37

|

8

|

|

PVC-200

|

63-200

|

SJZ65/132

|

Single outlet

|

37

|

3.5

|

|

PVC-315

|

110-315

|

SJZ80/156

|

Single outlet

|

55

|

3

|

|

PVC-630

|

315-630

|

SJZ92/188

|

Single outlet

|

110

|

1.2

|

|

PVC-800

|

560-800

|

SJZ105/216

|

Single outlet

|

160

|

1.3

|

Our Factory

Jiangsu Lianshun Machinery Co.,Ltd was founded in the year 2006. The factory area is more than 20000 square meters and has more than 200 staff.

For more than 20 years' R&D in plastic machine industry, Lianshun company has devoted to produce excellent plastic machine, such as plastic extruders, plastic(PE/PP/PPR/PVC) solid wall pipe machine, plastic(PE/PP/PVC) single/double wall corrugated pipe machine, plastic(PVC/WPC) profile/ceiling/door machine, plasitc washing recycling machine, plastic pelletizing machine, etc and related auxiliaries such as plastic shredders, plastic crushers, plastic pulverizers, plastic mixers, etc.

Lianshun company is dedicated to provide total solution including machine, mold, downstream and auxiliary equipment to customers world-wide. We can provide total solution for customers on turn-key basis. Until now, established good business relationship with more than 300 enterprises both in domestic and foreign countries with professional technology, quality products and efficient after-sale service including product tracking, optimization, employee training, etc. Our machines are firmly in the forefront of domestic market, with customers in more than 50 countries around the world.

Certifications

Exhibitions

Customers Vist Us

Customers in Our Conference Room:

Customers in Our Factory:

Dinners with Customers:

We Visit Customers

Welcome you!

Hot Searches