- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

300 KG

-

Product name:

-

High Frequency Washing Recycling Dewatering Vibrating Screen Plant

-

Material:

-

Cast steel

-

Dewatering Screen Power:

-

2x3kw

-

Fine Sand Separation:

-

350mm

-

Design:

-

All by our factory

-

Dewatering Screen Aera:

-

4 m*m

-

Pump Size:

-

3 inch

-

Advantage:

-

High efficiency

-

Spare Parts:

-

Supply

-

Visiting Working Site:

-

Welcome

Quick Details

-

Capacity(t/h):

-

50-300

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

baichy

-

Weight:

-

300 KG

-

Product name:

-

High Frequency Washing Recycling Dewatering Vibrating Screen Plant

-

Material:

-

Cast steel

-

Dewatering Screen Power:

-

2x3kw

-

Fine Sand Separation:

-

350mm

-

Design:

-

All by our factory

-

Dewatering Screen Aera:

-

4 m*m

-

Pump Size:

-

3 inch

-

Advantage:

-

High efficiency

-

Spare Parts:

-

Supply

-

Visiting Working Site:

-

Welcome

High-Frequency Gravel Gold Fine Sand Washer Recycling Machine Dewatering Vibrating Screen Machine Plant For Sale

The integrated sand washing and recycling machine can the improve the quality of sand (such as water content, large amount of mud, much dust, difficult and easy removal of impurities, etc.) and reduce the loses of sand in the processing of washing.

According to the customer's requirements, we can provide the integrated sand washing and recycling system, which is consisted of sand washer, dewatering screen, hydrocyclone, slurry pump, etc.

Features

1) Greatly reduce the mud, water, dust, impurities in the sand, greatly improving the quality of sand and increasing the benefits.

2) Low energy consumption and environmental protection.

3) Convenient transportation and quick installation.

4) Low failure rate and long service life.

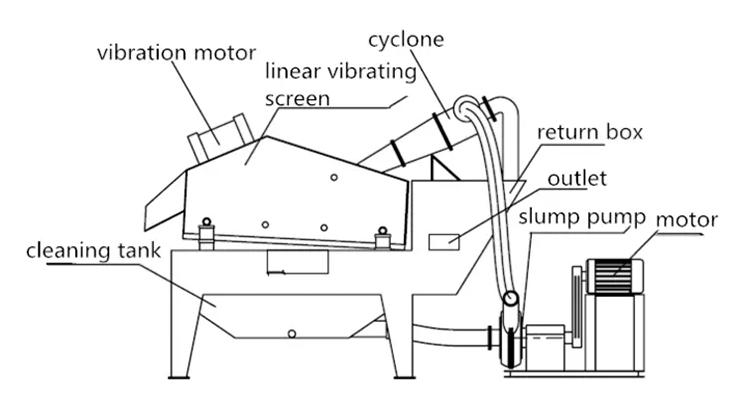

Working principle

Through rubber pipes sand and water mixture is extracted from cleaning tank into slurry pump. The fine sand is collected by the centrifugal force of the cyclone, then fed to the polyurethane screen from the apex spray. The 0.16-3mm fine sand and water are efficiently separated through the vibration screen. The waste water will flow back to the return box, through weld chute or pipes flowing to a settling pond.

| Model | Pump power(kw) | Sieve power(kw) | Capacity(m³/h) |

| HX250 | 7.5-11 | 0.75×2 | 50-80 |

| HX300 | 11-15 | 0.75×2 | 80-100 |

| HX350 | 18.5-22 | 0.75×2 | 100-120 |

| HX500 | 18.5-22 | 1.1×2 | 120-150 |

| HX600 | 22-30 | 1.1×2 | 150-200 |

| HX700 | 37-44 | 2.2×2 | 200-250 |

| HX1000 | 60 | 3×2 | 250-300 |

20 national service mileage:

Service mileage for local customers to provide equipment installation, commissioning and after-sales service

1. Are you manufacture or trading company?

We are factory, established in 2003.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at lowest cost.

5. If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.