- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110V 50Hz, 220V 50-60Hz

-

Power:

-

90W

-

Dimension(L*W*H):

-

127*57*47cm

-

Weight:

-

212

-

Applicable Industries:

-

laboratory

-

Product name::

-

glass reactor clamp

-

Stirring speed :(r/min):

-

20~600

-

Glass Cylinder Diameter::

-

20/23 cm

-

Glass material::

-

GG17 high borosilicate glass

-

Structure::

-

304 Stainless frame

-

Motor Torque (g/cm)::

-

4800

-

Other auxiliary::

-

Vacuum System

-

Explosion proof::

-

Optional

-

Heating method::

-

Circulating Water

-

Application::

-

Labs Research

Quick Details

-

Capacity:

-

5L

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUHUA

-

Voltage:

-

110V 50Hz, 220V 50-60Hz

-

Power:

-

90W

-

Dimension(L*W*H):

-

127*57*47cm

-

Weight:

-

212

-

Applicable Industries:

-

laboratory

-

Product name::

-

glass reactor clamp

-

Stirring speed :(r/min):

-

20~600

-

Glass Cylinder Diameter::

-

20/23 cm

-

Glass material::

-

GG17 high borosilicate glass

-

Structure::

-

304 Stainless frame

-

Motor Torque (g/cm)::

-

4800

-

Other auxiliary::

-

Vacuum System

-

Explosion proof::

-

Optional

-

Heating method::

-

Circulating Water

-

Application::

-

Labs Research

| YUHUA 50l double jacketed 200 liter glass reactor clamp |

Product Discription

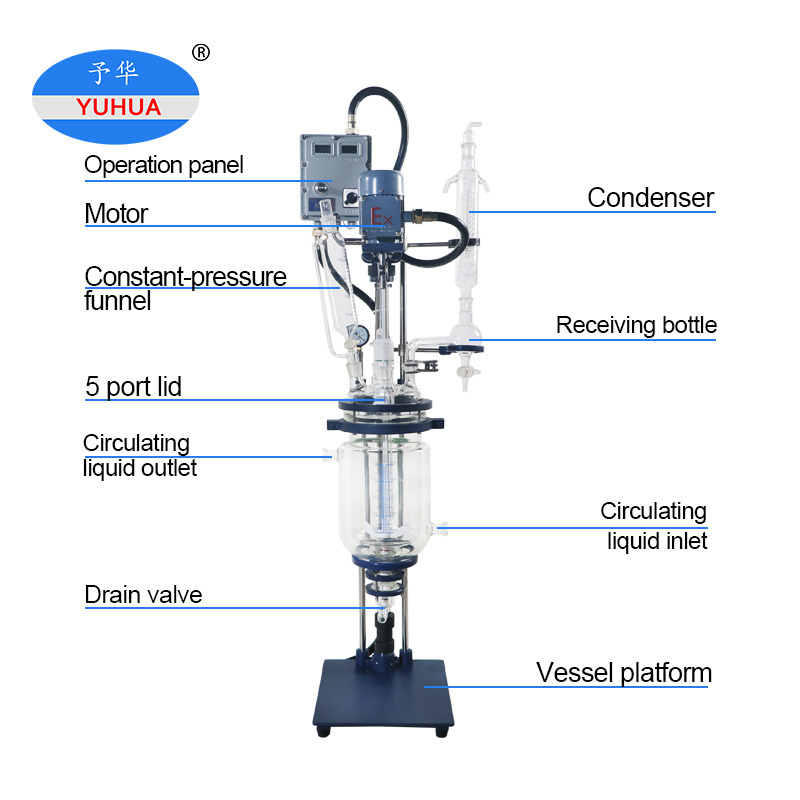

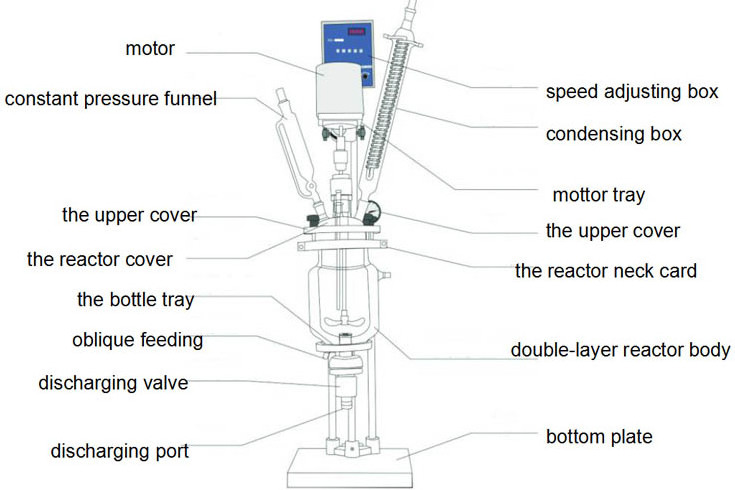

The double-layer glass reactor is a vessel in which chemical reactions are carried out. The double-layer reactor has two insulation layers which help in controlling the condition under which the reaction is carried out. For example, experts need glass reactors to control the temperature and pressure under which the chemical reaction is carried out.

The use of a double layer reactor allows for easy control of the reaction parameters. The first insulation layer can have a water layer that acts as insulation, while the second layer can have a vacuum unit that offers extra insulation.

Product Display

Features

The double-layer glass reactor comes with several features. There are several designs of double-layer reactors. The type of reactor you are using will determine the features you can access.

Here are features available in the double-layer reactor:

1. Vacuum jacket

There are two layers of protection in the double-layer reactor. The first jacket consists of a vacuum jacket. In the vacuum jacket, there is control of temperature and pressure. The chemical reactions are controlled due to the creation of a virtual vacuum.

2. Fluid jacket

Different types of fluids can be used in the process. The experts can apply fluids with certain chemical properties as a way of creating the right environment under which the chemical reactions will be carried out.

3. Reaction vessel

It is the vessel in which the chemical reactions occur. Different substances can be mixed in the reaction vessel to come up with the desired results. The reaction vessel contributes to the production of different desired outcomes.

YUHUA Double layer heating mantle Glass Reactor

Feature:1 .Vessel capacity is flexible from 1L-200L; Suitable for lab reasearch and pilot plant.

Feature 2 : Explosion-proof motor and AC servo motor optional, strong stirring;

Feature 3 : More than 5 agitator blades,suitable for widely viscosity range

Detail Specs

| Model | YSF-5 | YSF-10 | YSF-20 | YSF-50 | YSF-100 | YSF-200 |

| Reaction Volume(L) | 5L | 10L | 20L | 50L | 100L | 200L |

| Jacket Volume(L) | 2L | 5L | 8L | 12L | 18L | 25L |

| Reactor Material | High quality borosilicate 3.3 glass | |||||

| Support Frame Material | Stainless steel 304 and coated aluminum | |||||

| Neck No. On Lid | 5 | 6 | ||||

| Rated. torque(N.cm) | 140 | 177 | 177 | 177 | 285 | 550 |

| Motor power(W) | 90 | 120 | 120 | 120 | 200 | 370 |

| Rotating speed(rpm) | 0 ~ 600 (customizable) | |||||

| Power supply | 220V or 110V / 50-60HZ | |||||

| Discharge | PTFE (Teflon) bottom discharge valve with no deadspace | |||||

| Working Temp range | -60℃ ~ 200℃ | |||||

| Pressure Range | Full vacuum to atmosphere | |||||

| Max jacket pressure | 0.5 bar | |||||

How a Double-layer Glass Reactor Works

A double-layer reactor has two layers of insulation. The two layers help in controlling the conditions under which different processes are carried out in the reaction vessel.

The Applications of Double Layer Glass Reactors

Related products

Packing & Delivery

T

Why choose YUHUA?

As a leading supplier of laboratory equipment, Yuhua Instruments has gained a strong reputation for providing high-quality products that meet the needs of scientists and researchers in a variety of fields. While there are many other suppliers of laboratory equipment on the market, Yuhua Instruments stands out for its commitment to innovation, quality, and customer service.

1.Pricing and Value Advantages

We uses to produce its own goods and ODM. We also provide the transportation . Establish a real relationship with customer, feel more like a partner in business.

2.

Reduced Risk

On time delivery time, healthy financial shape, ISO9001 quality control system and experience in manufacturing to get an accurate picture of the risks involved in working with us.

3. 37 year’s Experience manufacturer

Since 1986, YUHUA established in Gongyi China. We insist on R&D, production, inspection and marketing. Now YUHUA and YUHUAYIQI are famous brand in China.

Our Certifications

Our Company

FAQ

1. Sample service;

Yes. YUHUA DNA is kind for all clients. And we have materials in stock to finish sample in short time.

2. Shiping service;

we have many kind shipping forwarders to support best shiping solution. And we have own plywood package department.

3. After-sale service;

we will take video and pictures to teach the installation. And our design and package way make set-up easily.

4. How long the warranty?

1 years for core parts,excpet glassware parts.

5. Pass Certification ?

ISO9001, CE, UL