- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

Customizable

-

Weight (KG):

-

300 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gondor

-

Voltage:

-

110V/220V

-

Dimension(L*W*H):

-

2100*780*1600mm

-

Power (kW):

-

3 kW

-

Marketing Type:

-

Hot Product

-

Inside structure:

-

Double ribbon blender

-

Discharge way:

-

Butterfly valve

-

Product type:

-

Powder , particle

-

Cylinder shape:

-

U shape

-

Mixing type:

-

Double ribbon mixer

-

Capacity:

-

100-3000L

-

Tank size:

-

1050*500*600mm

-

Machine type:

-

Horizontal industrial mixer

-

OEM/ODM Service:

-

Acceptable

-

Certification:

-

ISO 9001, ISO 14001, ISO 45001, CE, BSCI, ETL

Quick Details

-

Barrel Volume (L):

-

100

-

Max. Loading Volume (L):

-

3000 L

-

Range of Spindle Speed(r.p.m):

-

2 - 24 r.p.m

-

Max. Loading Capacity:

-

Customizable

-

Weight (KG):

-

300 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gondor

-

Voltage:

-

110V/220V

-

Dimension(L*W*H):

-

2100*780*1600mm

-

Power (kW):

-

3 kW

-

Marketing Type:

-

Hot Product

-

Inside structure:

-

Double ribbon blender

-

Discharge way:

-

Butterfly valve

-

Product type:

-

Powder , particle

-

Cylinder shape:

-

U shape

-

Mixing type:

-

Double ribbon mixer

-

Capacity:

-

100-3000L

-

Tank size:

-

1050*500*600mm

-

Machine type:

-

Horizontal industrial mixer

-

OEM/ODM Service:

-

Acceptable

-

Certification:

-

ISO 9001, ISO 14001, ISO 45001, CE, BSCI, ETL

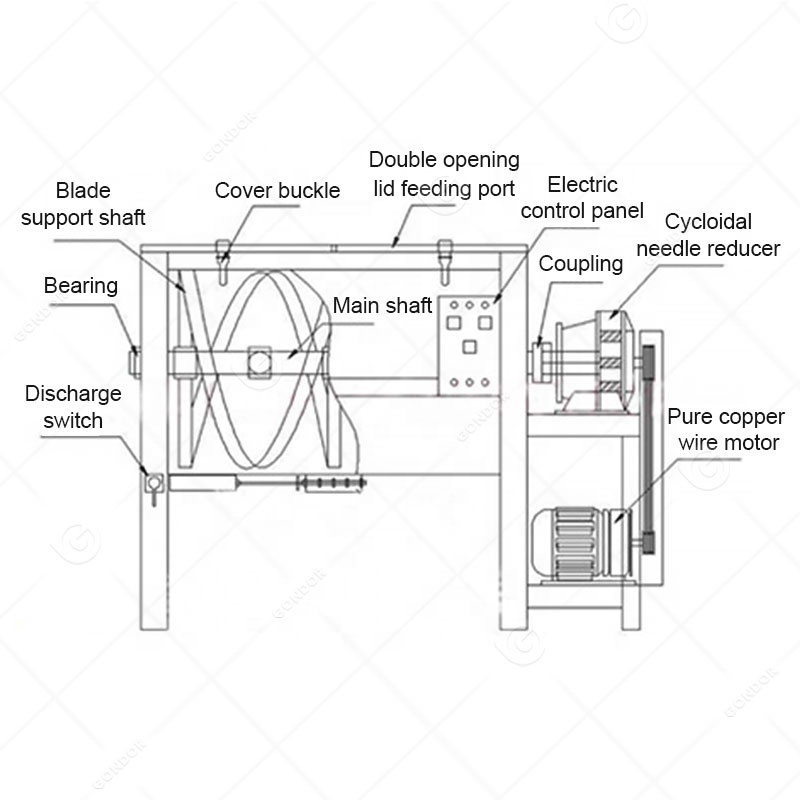

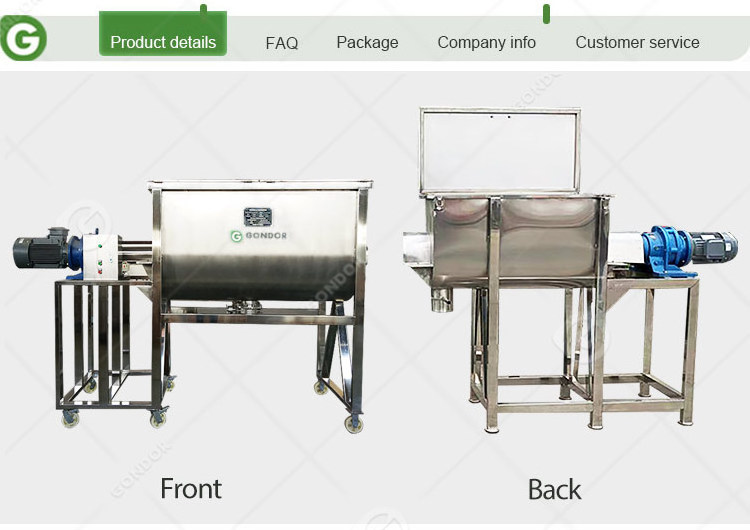

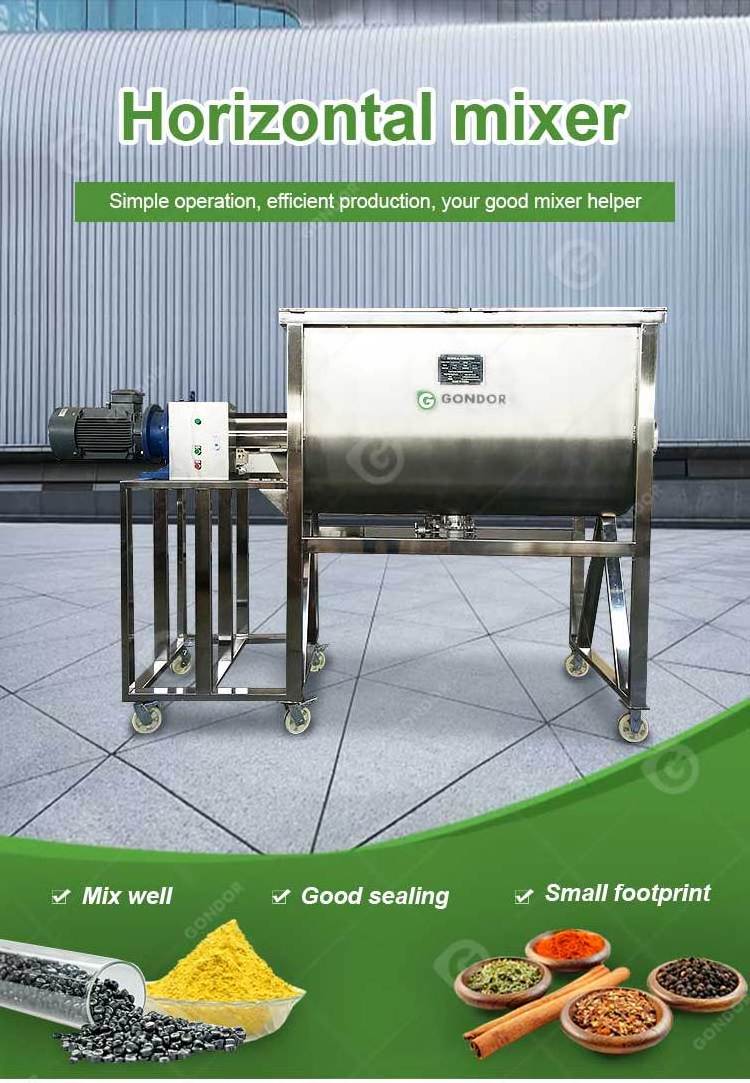

Introduction

Horizontal mixer is a professional for all kinds of granules, powders, flakes and particles of uniform mixing needs of efficient equipment. The machine adopts horizontal body and spiral belt mixing, which has the advantages of small floor space, easy operation, simple maintenance, high uniformity, small residue, good sealing, no vibration, small dust, etc.

Application

1. Horizontal mixer is mainly used for mixing corn, chili powder, spices, feed, flour, soybean powder, feed additives and other objects.

2 . Horizontal mixer is widely used in chemical industry, food industry, construction, fertilizer and agricultural industry, environmental industry, cosmetics and personal care. Application of a horizontal mixer spans across multiple industries, where efficient and consistent blending of ingredients is essential for product quality, productivity, and customer satisfaction.

Features

1. Horizontal tank, covers a small area.

2 . Vertical/oblique discharge port, no dead Angle.

3 . Two-way S-type screw belt, mix evenly.

4 . Cover the design and seal well.

5 . Spindle can be customized according to material density.

Paramater

| Model | Capacity | Size of mixing tank(m) | Thickenss of machine's body | Thickness of the rlbbon | Power(kw) | Reductor |

| GD-300 | 300L | 1.05*0.5*0.6 | 2mm | 6mm | 3 | 200 |

| GD-500 | 500L | 1.2*0.65*0.7 | 2mm | 6mm | 4 | 250 |

| GD-700 | 700L | 1.22*0.73*0.85 | 2mm | 8mm | 5.5 | 250/350 |

| GD-1000 | 1000L | 1.5*0.8*0.95 | 2mm | 8mm | 7.5 | 350 |

| GD-1500 | 1500L | 1.8*0.9*1.05 | 2mm | 8mm | 7.5 | 350 |

| GD-2100 | 2100L | 2*1*1.15 | 2mm | 8mm | 11 | 350 |

| GD-3200 | 3200L | 2.2*1.2*1.35 | 2mm | 8mm | 11-15 | 350 |

| GD-4300 | 4300L | 2.5*1.26*1.45 | 2mm | 8mm | 15-18.5 | 350 |

| GD-6400 | 6400L | 2.9*1.5*1.65 | 4mm | 8mm | 22 | 500 |

| GD-8000 | 8000L | 4mm | 10mm | 37 | 650 | |

| GD-10M | 10M² | 3.7*1.6*1.9 | 4mm | 12mm | 37 | 650 |

| GD-10M-2 | 10M² | 6mm | 12mm | 37 | 650 | |

| GD-15M | 15M² | 4.5*1.85*2.05 | 6mm | 12mm | 45 | 750 |

| You can customize 201 bracket carbon steel, all 201, contact 304 bracket 201, all 304 materials | ||||||

Q1. What is a horizontal mixer?

A horizontal mixer is a type of mixing equipment that blends ingredients in a horizontal orientation, ensuring thorough and uniform mixing of various substances.

Q2. What are the key advantages of using a horizontal mixer?

Some key advantages of a horizontal mixer include its ability to achieve consistent mixing results, handle a wide range of materials, offer high mixing efficiency, and provide easy access for cleaning and maintenance.

Q3. What industries can benefit from a horizontal mixer?

Horizontal mixers find application in various industries, including food, bakery, confectionery, chemical, agricultural, and environmental sectors, where precise and efficient ingredient blending is required.

Q4. What types of materials can be mixed in a horizontal mixer?

Horizontal mixers can handle a wide range of materials, including powders, granules, liquids, pastes, doughs, and other substances used in food processing, chemical manufacturing, and more.

Q5. Can a horizontal mixer handle different batch sizes?

Yes, horizontal mixers are designed to accommodate different batch sizes, ranging from small-scale operations to large-scale industrial production, ensuring flexibility and scalability in the mixing process.

Installing waterproof membrane to reduce dust and water pollution

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation

Delivery Time

For stock type, we can send within 48hrs after confirming order.

For customized type , delivery date need to be negotiated before taking order.