- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Xianhe

-

Year:

-

2020

-

Voltage:

-

380V/220V

-

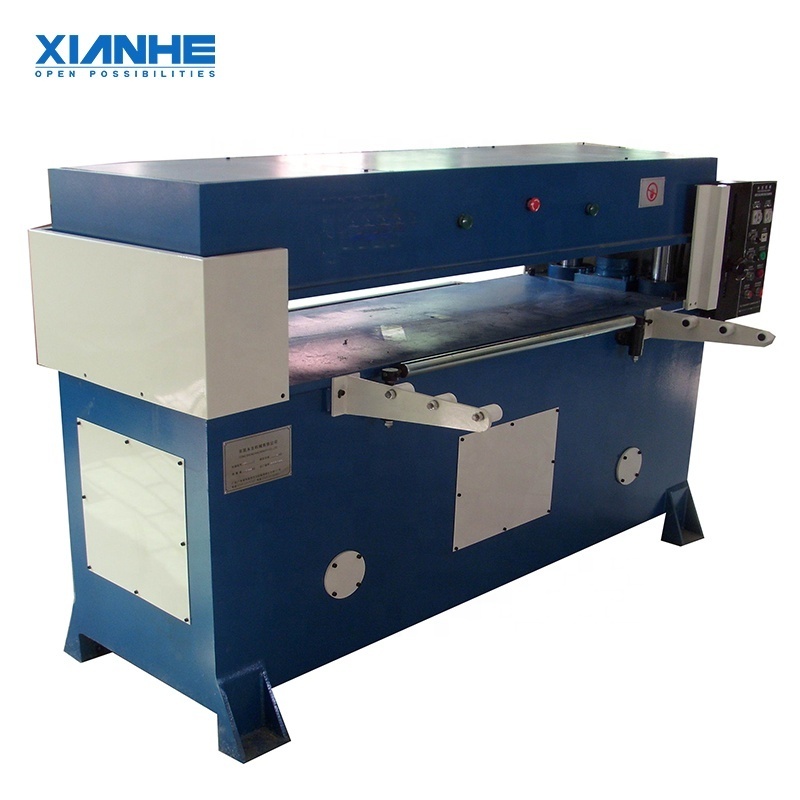

Dimension(L*W*H):

-

2280*1300*1520mm

-

Weight (T):

-

1.7 T

-

Model Number:

-

P4-40T

-

Motor Power (kw):

-

2.5 kw

-

Power Source:

-

Hydraulic

-

CNC or Not:

-

CNC

-

Cutting table size:

-

1600*800mm

-

Stroke range:

-

50-240mm

-

Cutting force:

-

40 Ton

-

Application:

-

Non metal materials

-

Working width:

-

1600mm

-

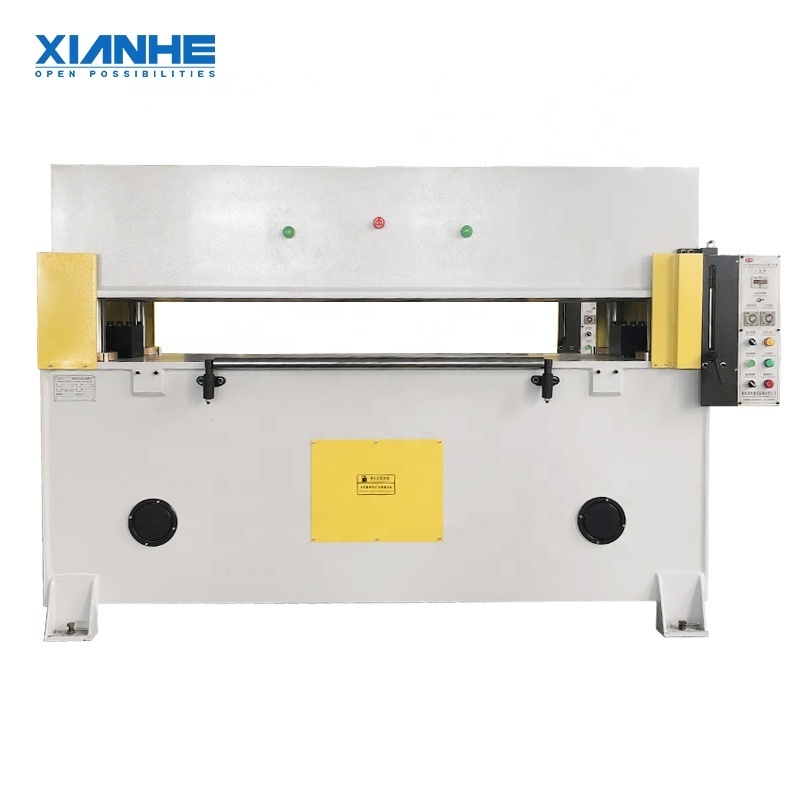

Color:

-

Blue, Yellow, White, Green

-

Motor Power (kW):

-

4kW

-

Suitable material:

-

Rubber/EVA Foam/Fabric/Paper/Plastic

Quick Details

-

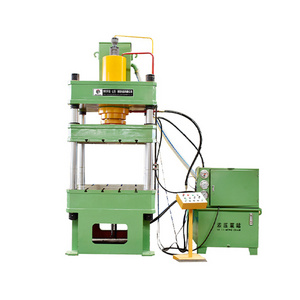

Machine Type:

-

Four-column Four-beam Hydraulic Press

-

Slide Stroke (mm):

-

50-180mm

-

Return Force (kN):

-

400 kN

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Xianhe

-

Year:

-

2020

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

2280*1300*1520mm

-

Weight (T):

-

1.7 T

-

Model Number:

-

P4-40T

-

Motor Power (kw):

-

2.5 kw

-

Power Source:

-

Hydraulic

-

CNC or Not:

-

CNC

-

Cutting table size:

-

1600*800mm

-

Stroke range:

-

50-240mm

-

Cutting force:

-

40 Ton

-

Application:

-

Non metal materials

-

Working width:

-

1600mm

-

Color:

-

Blue, Yellow, White, Green

-

Motor Power (kW):

-

4kW

-

Suitable material:

-

Rubber/EVA Foam/Fabric/Paper/Plastic

Hydrualic press machine hand operating press No-uese hydraulic press machine:

Product Description

Use and characteristics

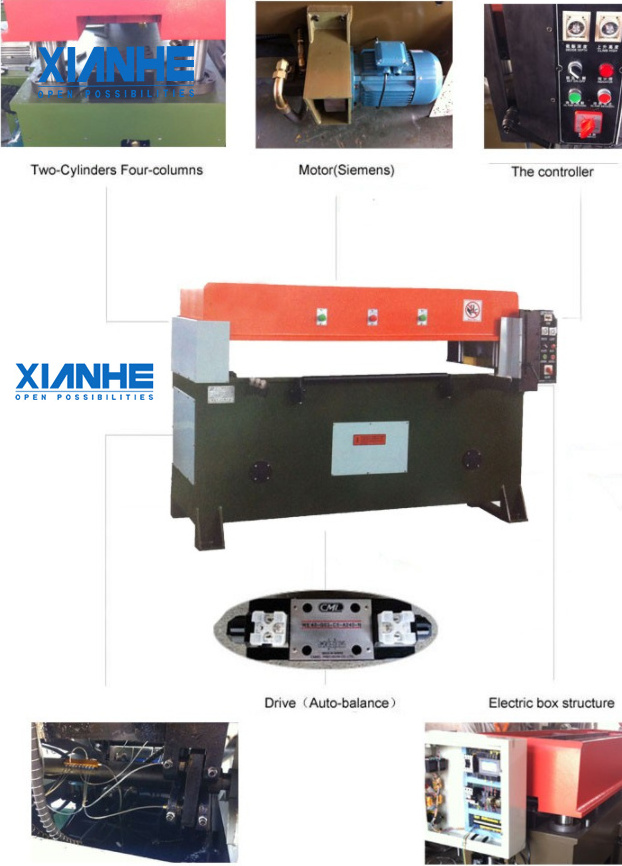

1. This Hydraulic leather Cutting Machine is mainly suitable for cutting various nonmetal materials,

Such as leather, EVA, Foam, Rubber, Pu Clothing Material,Tumbling Pu Clothing Leather and so on.

2.

Adopt double oil cylinder, precise double crank connecting rod mechanism, which can guarantee that the cutting depth at every cutting position is same.

3. The clicking machine can suppot single-side or double-side automatic feed attachment and raise the working efficient of the whole machine by two or three time.

4.

Equipped with cutting board micro-movement device,ensure the consumption of cutting board is low,save cost

the leather hydraulic die cutting press machine.

5. When the cutting board of die cutting machine contacts the die cutter,it will carry out slow cutting,

so that ensure there is no size error between the uppermost layer and lowermost layer of cut materials.

so that ensure there is no size error between the uppermost layer and lowermost layer of cut materials.

6.

The materials are driven by the servo motor and input from one side of machine,

and after die cutting, output from the other side, which can guarantee accurate feeding and stable operation.

7. With special setting mechanism,and in conjunction with die cutter and cutting depth setting,the travel adjustment is simple and accurate.

8

. Center automatic lubrication system can quarantee the precision and can raise abrasive resisitance.

9

.

We will meet the customers’ needs, making the hydraulic precision four-column die cutting press machine on request.

Main Technical Data(Customizable)

| Model | P4 | ||||||

| Maximum cutting force | 30T | 35T | 400T | 500T | 600T | 800T | 1000T |

| Working table(mm) | 1600*500 | 1600*610 | 1600*610 | 1600*800 | 1600*800 | 1600*900 | 1600*900 |

| Main motor power(kw) | 1.5 | 3 | 3 | 4 | 5.5 | 7.5 | 7.5 |

| Machine weight(kg) | 1600 | 2300 | 1600 | 3200 | 4200 | 4600 | 7000 |

Packaging & Shipping

Hot Searches