- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

220v/380v

-

Power:

-

7.2kw

-

Dimension(L*W*H):

-

6000*1400*1400mm

-

Weight:

-

700 KG

-

Machinery Function:

-

washing machine

-

Output product name:

-

Bubble washing machine

-

Productivity:

-

50-90000KG/hr

-

Capacity:

-

Customized

-

Advantage:

-

High Working Efficiency

-

Operation:Full-automatic:

-

Highly automated operation

-

Material:

-

Stainless Steel 304

-

Heating Source:

-

Integral lifting or heating function is optional.

-

Customized:

-

Support customized design

-

Used for:

-

Reduce labor force

-

Washing type:

-

washing and decontamination

-

our services:

-

Complete equipment solution

Quick Details

-

Raw material:

-

Corn, Fruit, Vegetables, Milk, Nuts

-

Model Number:

-

QXJ-GS-7000

-

Brand Name:

-

Haright

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

220v/380v

-

Power:

-

7.2kw

-

Dimension(L*W*H):

-

6000*1400*1400mm

-

Weight:

-

700 KG

-

Machinery Function:

-

washing machine

-

Output product name:

-

Bubble washing machine

-

Productivity:

-

50-90000KG/hr

-

Capacity:

-

Customized

-

Advantage:

-

High Working Efficiency

-

Operation:Full-automatic:

-

Highly automated operation

-

Material:

-

Stainless Steel 304

-

Heating Source:

-

Integral lifting or heating function is optional.

-

Customized:

-

Support customized design

-

Used for:

-

Reduce labor force

-

Washing type:

-

washing and decontamination

-

our services:

-

Complete equipment solution

vegetable washing machine.

meat washing machine

food washing machine.

|

Product Description

|

|

|

|

power supply

|

380v/50hz

|

|

|

Power

|

7kw

|

|

|

washing series

|

3 level

|

|

|

Health series

|

Food grade

|

|

|

Clean production

|

200-9000kg/h

|

|

|

washing and peeling

|

Different products with different yields

|

|

|

Air drying series

|

3 level

|

|

|

The equipment size

|

6000*1300*1400mm

|

|

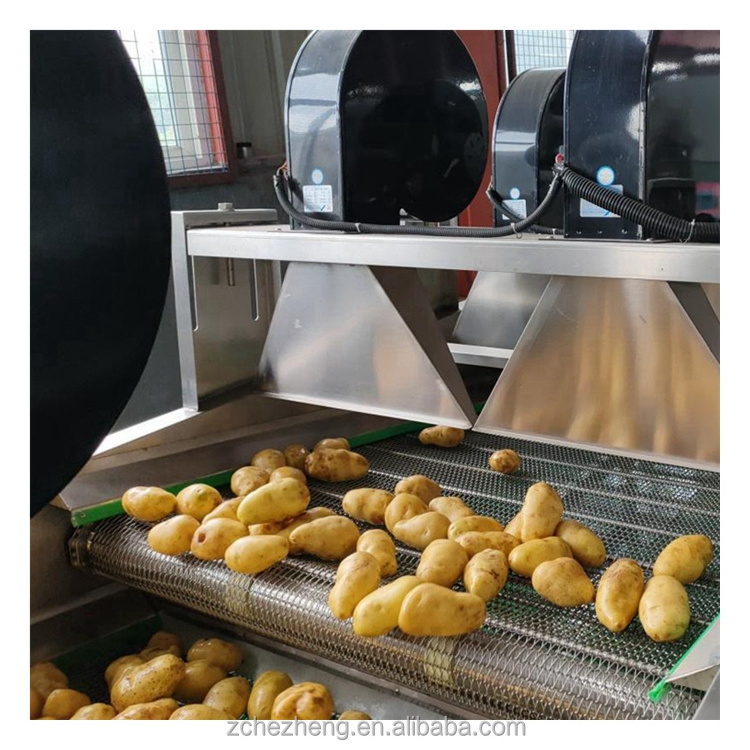

Products suitable for using this machine.

Can be widely used in vegetables, meat, aquatic products, frozen food, canned food, prepared food and many other industries. It can save 70% of water consumption and 10-200 people compared to manual cleaning mehods.

It replaced heavy manual labor and realized the mechanization of food processing

.

Effect comparison

PRODUCT DETAILS

1. Made of 304 stainless steel material Choose thickened stainless steel material, durable, equipment is more stable and strong, long service life。

2. Integrated control panel, one-click operation, easy to operate Control panel for pumps, conveyor , high-pressure spray, individual design, safe operation, time saving.

3. Adopts cleaning method of bubble surfing and high-pressure flushing can make the material in the machine clean more comprehensively and cleanly.

4. Material is cleaned by water flow of the high-pressure water pump, there is a second spray cleaning, which greatly improves cleaning effect.

5. wide application, one set washing machine can realize several material cleaning, professional production, customized on demand.

COMPANY PROFILE

professional global supplier of food industry equipment

Zhucheng Hezheng Machinery Technology Co., Ltd. is a professional food industry equipment operation manufacturer that integrates product design and development, production and manufacturing, operation and sales, engineering installation, and after-sales service. The company specializes in the production of turnover container cleaning and disinfection, air drying (drying) assembly lines; Thawing, dividing, pre cooking, and braising lines for meat products; Fruit and vegetable product cleaning, blanching (blanching) assembly line; Fully automatic pasteurization cooling assembly line; Leisure food cleaning and air drying (drying) assembly line; Vacuum rapid cooling equipment; Automated food machinery assembly lines for sorting, spreading, and conveying.

|

17 years of specialization in industry

|

|

Offer professional advice, design suitable solution

|

|

Onsite service and online service optional for installation and commissioning

|

COOPERATION PARTNERS

|

Complete equipment solution

|

|

1.Provide customized project design in 12hours,Offer professional advice, design suitable solution.

|

|

2.The products adopt advanced production technology and components at home and abroad, with novel structure, stable performanceand qualified quality.

|

|

3.Inspection each manufacturing step Always third party inspect and sign for final Inspection before shipment.

|

|

4.Keep 24 hours online to answer customers inquiry and online message,The lifelong maintenance, only charge material fee.

|

WAREHOUSE DELIVERY

|

Q: What methods of payment are acceptable?

|

|

A: Telegraphic transfer : we accept 50% deposit before production and 50% balance before shipment.

|

|

Q: What is the cost of shipping?

|

|

A: Shipping cost is based on the following elements

1. Number of packages 2.Gross Weight 3. Package volume 4. Destination port |

|

Q:How about the delivery time?

|

|

A: 20-50 working days depends on your requirement and the size of machine.

|

|

Q: How to package?

|

|

A: We will pack the machine by plywood to moisture-proof, anti shake,preventing damage or according to your request.

|

|

Q: Evaluation during design?

|

|

A: Inspection each manufacturing step Always third party inspect and sign for final Inspection before shipment.

|

|

Q: fter-sale service?

|

|

A: 1. One year warranty time except the easy-damaged parts

2. The lifelong maintenance, only charge material fee 3. Installation and commissioning about 7-10 workingdays, Supplying installation training if you install it by yourself. 4.Retraining the operator by making normative commissioning. procedure for equipment, enable it parameterization and standardization to up to the production conditions reasonable. |

Hot Searches