- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

professional solution hydraulic aluminum metal chips scrap briquette p

-

Application:

-

Briquette Production

-

Keyword:

-

Hydraulic Briquette Machine Press

-

Color:

-

Client's Required

-

Pressure type:

-

Hydraulic Pressure

-

Briquette shape:

-

Round

-

Features:

-

Eco-friendly

-

Quality:

-

Advanged Technology

-

Raw material:

-

Iron Powder

-

Function:

-

Energy Saving

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shuliy

-

Certification:

-

CE ISO

-

Product name:

-

professional solution hydraulic aluminum metal chips scrap briquette p

-

Application:

-

Briquette Production

-

Keyword:

-

Hydraulic Briquette Machine Press

-

Color:

-

Client's Required

-

Pressure type:

-

Hydraulic Pressure

-

Briquette shape:

-

Round

-

Features:

-

Eco-friendly

-

Quality:

-

Advanged Technology

-

Raw material:

-

Iron Powder

-

Function:

-

Energy Saving

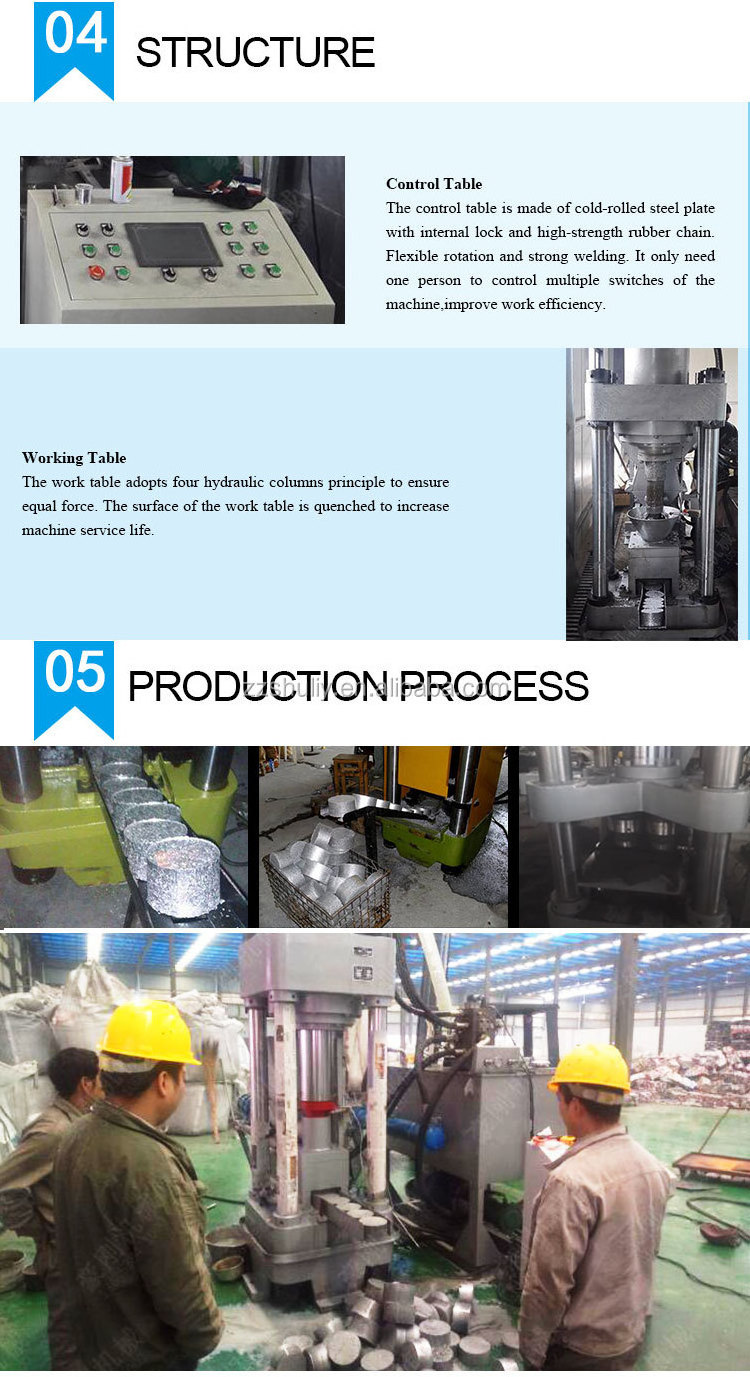

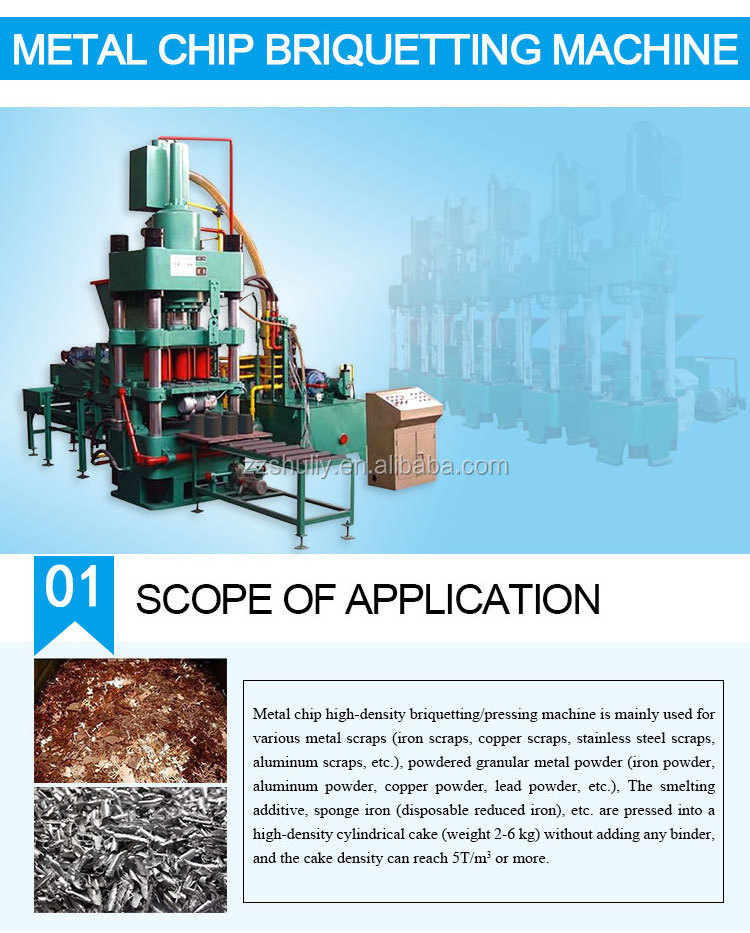

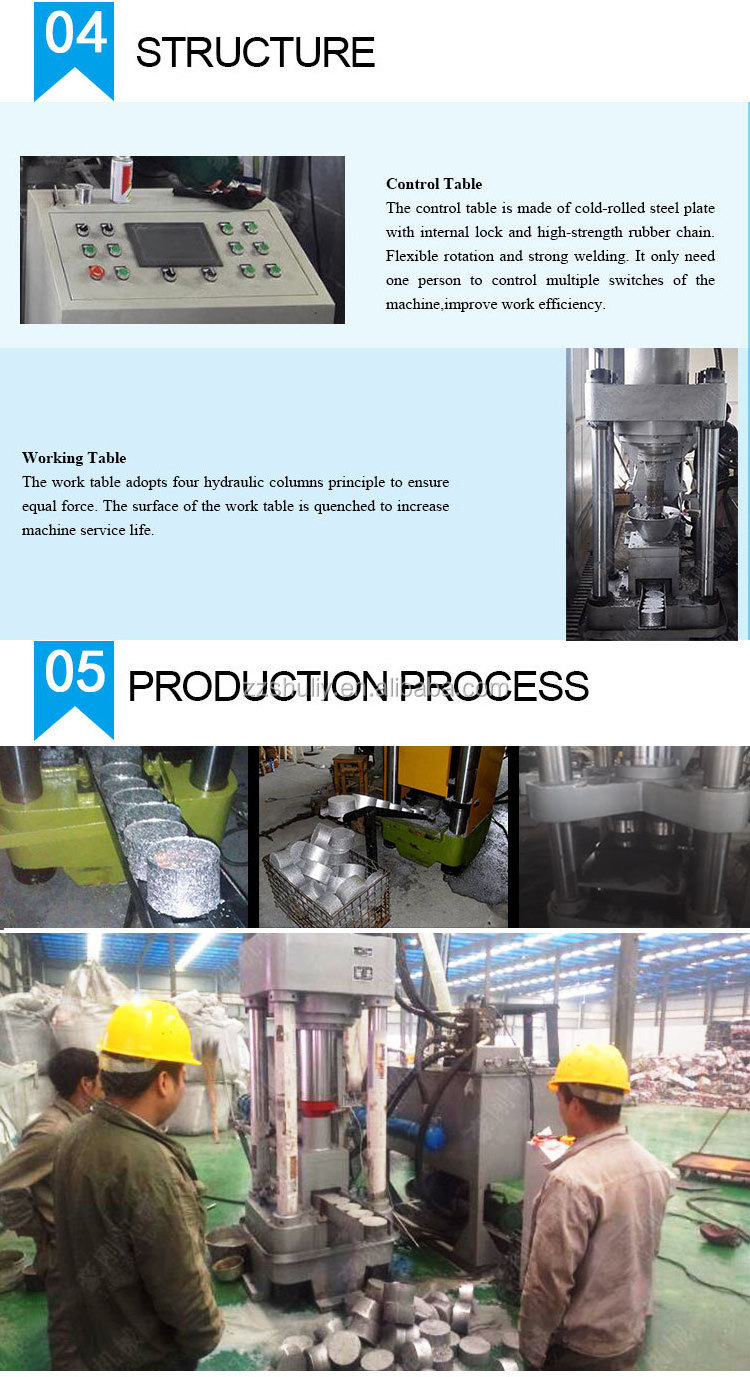

Metal Chip Briquetting Machine/Metal Chips Pressing Machine

Information of Metal Chip Press Machine

Metal chip briquette machine is specialized in waste metal recycling equipment, The material which has been compressed by briquetting press has the features of high density, strong strength, easy to transport, high waste utilization, good economic benefit and social benefit. It's a wonderful energy saving and environmental protection equipment.

Detailed Information of Metal Chip Press Machine

1.The metal chip pressing machine frame adopts integral steel castings to prevent cracking of the welded parts of the steel plate, which improves the reliability and service life of the equipment.

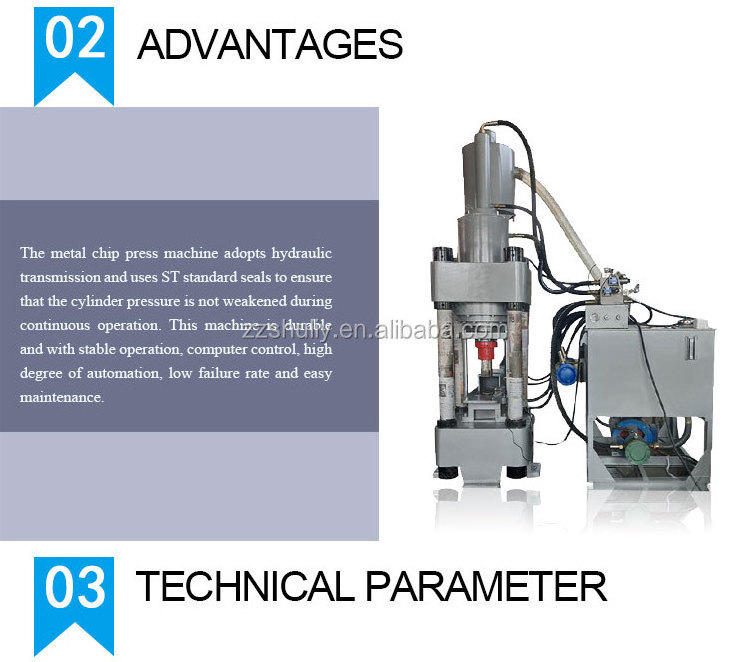

2.Using advanced hydraulic transmission technology and superimposed combination valve block, using high-quality wear-resistant oil seal, the cylinder is processed and assembled by the latest high-tech technology in China, thus ensuring continuous operation without weakening the cylinder pressure, durable and stable operation.

3.Computer control, high degree of automation, low failure rate, easy maintenance.

4.According to the user's situation, the screw automatic feeder and the chain automatic discharge are used to reduce the labor intensity of the workers.

|

Model |

Stock Bin Size(mm) |

Bag size(cm) |

Molding Time(s)

|

Power(kw) |

|

Y81-125 |

1200*800*500 |

30*30 |

100 |

15 |

|

Y81-135 |

1200*1000*600 |

30*30 |

110 |

18.5 |

|

Y81-160 |

1200*1000*600 |

35*35 |

110 |

18.5 |

|

Y81-180 |

1600*1200*800 |

40*40 |

130 |

22 |

|

Y81-200 |

1600*1200*800 |

50*50 |

140 |

22+15 |

|

Y81-250 |

2000*1750*1000 |

50*50 |

150 |

44 |

|

Y81-315 |

2500*2000*1200 |

60*60 |

160 |

60 |

|

Y81-400 |

3000*2500*1200 |

60*60 |

170 |

90 |

Related Machines