- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Machine Type:

-

Composite Thermal Spraying Production Line, Spray Booths, Painting Equipment, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Conveying Equipment, Drying Oven, Curing oven, Coating Equipment, Anodized Equipment, Sandblasting Machine, Other

-

Place of Origin:

-

China

-

Weight (KG):

-

1000

Product Overview

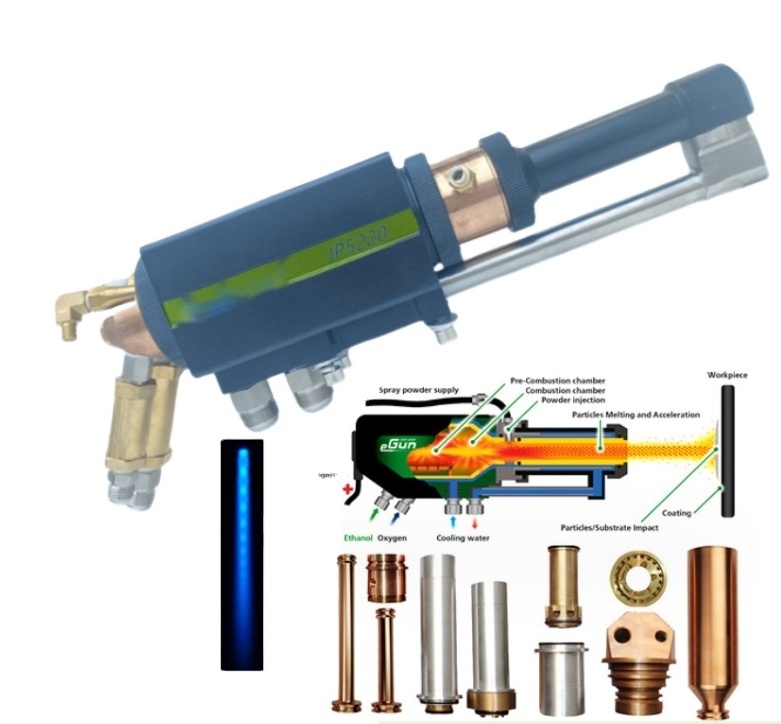

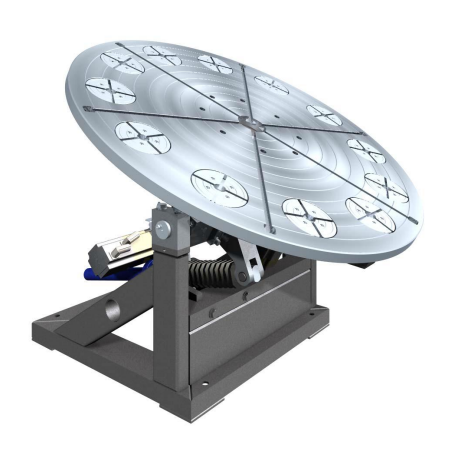

HP HVOF & APS Plasma Spray Composite Thermal Spraying Production Line

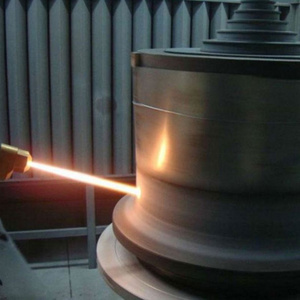

Using HP HOVF and APS plasma spraying methods, the workpiece is continuously sprayed using a robotic arm and spraying equipment in sequence. Ensure that the provided equipment solution meets the customer's processing requirements for workpiece spraying.

Intended to replace the domestic high-quality classic equipment of Praxair JP5000 and Metco F4 in the United States, providing high-quality spraying services for industrial fields including steel, shipbuilding, aerospace, cardboard machinery, paper machinery, plastic machinery, petrochemical machinery, and general machinery.

We use legitimate manufacturers with production licenses for all raw materials and internal components. Our core and main components are imported from global famous brands, with a coverage rate of over 90% for imported parts. We strictly conduct product inspections. The operating performance in the past decade or so has shown that the equipment produced by our company has stable and reliable performance, and has a good user reputation!

Advantages Introduction:

1) At present, the best alternative to imported equipment in China is equivalent to the spraying quality of USA equipment.--Up to five years no need maintenance!

2) Short delivery time , only 1-2 months.

3) Support the validation of equipment through small, medium, and large batch spraying processing testing.

4) Tailored and systematic spraying recommendations.

5) Easy to wear parts and accessories are complete, without any worries.

6) Professional after-sales team, high-quality and fast service.

7) Full service, providing comprehensive solutions for all processes/materials /accessories / accessories/ applications/spraying testing from conceptual design to actual production in the later stage.--Provide A/S solution within 1 hour, provide 7X24 hour hotline telephone support service, and be responsible for providing answers to technical questions and technical guidance!

FEATURES AT A GLANCE

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hot Searches