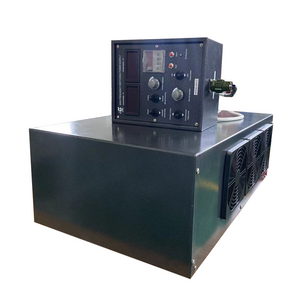

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Haney

-

Model Number:

-

HN--4000A

-

Output Frequency:

-

50/60hz

-

Output Current:

-

4000amp

-

Efficiency:

-

90%

-

Certification:

-

CE ROHS

-

Warranty:

-

12 Months

-

Protections:

-

Shortcuit Overtemp Overload Overtemp

-

Output frequency:

-

50/60hz

-

Application:

-

Plating,anodizing,metal finishing,surface treatment

-

Cooling type:

-

air cooling or water cooling

-

Power:

-

customized

-

Product Name:

-

electroplating rectifier/dc power supply for plating

-

Packing:

-

wood carton

Quick Details

-

Output Power:

-

>500W

-

Input Voltage:

-

220/380/415/440v

-

Output Voltage:

-

12v15V24v36v48vOEM

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Haney

-

Model Number:

-

HN--4000A

-

Output Frequency:

-

50/60hz

-

Output Current:

-

4000amp

-

Efficiency:

-

90%

-

Certification:

-

CE ROHS

-

Warranty:

-

12 Months

-

Protections:

-

Shortcuit Overtemp Overload Overtemp

-

Output frequency:

-

50/60hz

-

Application:

-

Plating,anodizing,metal finishing,surface treatment

-

Cooling type:

-

air cooling or water cooling

-

Power:

-

customized

-

Product Name:

-

electroplating rectifier/dc power supply for plating

-

Packing:

-

wood carton

HN auto reverse igbt electroplating rectifier for zinc copper nickel chrome plating line

Features:

1.Infineon drive chip,Infineon IGBT,China SL nitrates,rectifier bridge,Germany

2.Running state:24hours operation with a full load

3.Full-bridge high-frequency

4.Digital display,5m remote control

5.CE approve

6.Forced air or water cooling

7.It protect against under-voltage,over-voltage,phase loss,short circuit,over-current and over-heating

8.It is used for metal finishing, surface treatment;

9.All specifications can be custom made as your requirement.

|

Description

|

Rectifier Electroplating & Surface treatment dc power supply

|

|

Item No.

|

HN-10000

|

|

AC input voltage

|

Three phase 220V, 380V, 415V, 480V±10%, 50/60Hz

|

|

Output voltage

|

DC 0-12/24/36/48V...300V adjustable

|

|

Output current

|

DC 0-100/200/300/400/500A/1000A....30000A adjustable

|

|

Regulation range

|

0-100%

|

|

Power factor

|

≥0.9(full load)

|

|

Accuracy of output current, voltage

|

≤0.1%

|

|

Efficiency

|

≥90%(full load)

|

|

Protection grade

|

IP54 for water cooling, IP30 for forced air cooling

|

|

Cooling method

|

air cooling or water cooling

|

|

Control mode

|

Pulse remote control

|

|

Operation mode

|

Local touch screen, front pannel, remote control box or communication

|

|

Communication protocol

|

RS485, Profibus DP, MODBUS

|

|

Working method

|

Long time full load continuous operation

|

|

Protections

|

Overheat, input over/under voltage, output overvoltage, output overcurrent, over water temperature, under water pressure.

|

|

Related items

|

electrowinning power supply,anodizing rectifier,electrolysis rectifier,chrome rectifier,IGBT rectifier....

|

How Does Rectifier Work In Electroplating?

Electroplating rectifier is a high frequency switching power supply unit that can convert AC (AC) to DC (DC). turn ac (AC) into dc(DC) and provide to load or inverter after smoothing ,then provide charging voltage to battery.

The plating rectifier has a transformer that reduces the voltage, diodes responsible for the conversion, a control system for both the voltage and the current, a device for cooling the rectifier and overload protection. Regarding the control system,we provide standard control box,RS485 control box,timing control box and touch screen automatic commutation system for optional.

Applicating in plating process : In the salt solution containing the metal to be plated, the substrate metal to be plated is used as the cathode, and the cations to be plated in the plating solution are deposited on the surface of the substrate metal by electrolytic.

What Sets Haney Equipment Apart?

1. Lower cost of operation

2. Compact design ( rack & modular configurations)

3. Inherently low ripple

4. Higher full range efficiency

5. Higher full range power factor

6. Local and remote automation capabilities

Haney electroplating rectifier with Stainless Steel Enclosures are meant to handle the chemical abuse and hang right on the wall or conveniently near your operating process.

The RS485 Controllers equiped for plating rectifier allow for process control, cycle function, voltage and current set-point control and digital DC ammeters and voltmeters. Thus Our rectifiers are easy to troubleshoot since the controller will tell you exactly what’s wrong. This takes the guesswork out of maintenance and problem solving—which saves money and time.

In a perfect world, our electroplating rectifier are designed to last roughly 20 years. However, depending on your water quality or equipment treatment, we’ve seen many customers get at least 10 years of their Haney units.

Haney plating rectifiers are designed for customers that need quality and individualized control in their manufacturing lines. Our units are versatile , Space Efficient , and Easily Integrated Into Your Line .

Haney Equipment Has Won A Large Number Of Good Comments Around The World.

1. Lower cost of operation

2. Compact design ( rack & modular configurations)

3. Inherently low ripple

4. Higher full range efficiency

5. Higher full range power factor

6. Local and remote automation capabilities

Haney electroplating rectifier with Stainless Steel Enclosures are meant to handle the chemical abuse and hang right on the wall or conveniently near your operating process.

The RS485 Controllers equiped for plating rectifier allow for process control, cycle function, voltage and current set-point control and digital DC ammeters and voltmeters. Thus Our rectifiers are easy to troubleshoot since the controller will tell you exactly what’s wrong. This takes the guesswork out of maintenance and problem solving—which saves money and time.

In a perfect world, our electroplating rectifier are designed to last roughly 20 years. However, depending on your water quality or equipment treatment, we’ve seen many customers get at least 10 years of their Haney units.

Haney plating rectifiers are designed for customers that need quality and individualized control in their manufacturing lines. Our units are versatile , Space Efficient , and Easily Integrated Into Your Line .

Haney Equipment Has Won A Large Number Of Good Comments Around The World.

What Haney Equipment Provide For Metal Finishing Process?

Haney Equipment is widely used in metal finishing including gold, silver, zinc, nickel, copper, chrome, anodizing, electrolysis, electrophoresis and provide a wide range of equipment accessories: IGBT rectifier,industrial chiller,PP/PVC tank,immersion heater,filter ,etc.

Haney Equipment is widely used in metal finishing including gold, silver, zinc, nickel, copper, chrome, anodizing, electrolysis, electrophoresis and provide a wide range of equipment accessories: IGBT rectifier,industrial chiller,PP/PVC tank,immersion heater,filter ,etc.

Application for:

Automatic anodizing line

Electroless nickel plating line

Hard chrome plating line

Metal plating line

Nickel/copper/gold barrel plating line

PCB plating line

Plastic plating line

Packaging & Delivery

1.Foam inside,Wooden box outside packing.

2.7-15 days after payment.

Hot Searches