- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HaoFeng

-

Model Number:

-

Custom

-

Torque:

-

8

-

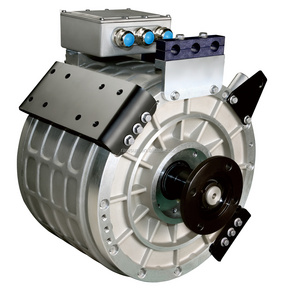

Housing:

-

Aluminum Frame

-

Speed Range:

-

3000rpm

-

Material:

-

Permanent Magnets

-

Controller:

-

Customized, Optional

-

Braker:

-

Optional

-

Insulation Class:

-

Class F

-

Enclosure:

-

IP54

-

Poles:

-

4P, 6P, 8P...

-

Wire:

-

100% copper

-

Duty:

-

S1 (continuous)

Quick Details

-

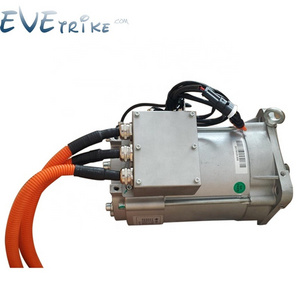

Speed(RPM):

-

custom

-

Continuous Current(A):

-

custom

-

Efficiency:

-

custom

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HaoFeng

-

Model Number:

-

Custom

-

Torque:

-

8

-

Housing:

-

Aluminum Frame

-

Speed Range:

-

3000rpm

-

Material:

-

Permanent Magnets

-

Controller:

-

Customized, Optional

-

Braker:

-

Optional

-

Insulation Class:

-

Class F

-

Enclosure:

-

IP54

-

Poles:

-

4P, 6P, 8P...

-

Wire:

-

100% copper

-

Duty:

-

S1 (continuous)

| IEC #100/112 | 220VAC (Customized DC 24/48/60/72/96V) | ||||||

Rated output |

KW | 2.25 | 3.75 | 5.5 | |||

Rated torque |

N.m |

21.49 |

35.81 | 23.88 | 11.94 | 35.02 | 17.51 |

Rated current |

A | 8.54 | 14.23 | 14.23 | 14.23 | 20.87 | 20.87 |

Rated speed |

rpm | 1000 | 1000 | 1500 | 3000 | 1500 | 3000 |

| Peak torque | N.m | 64.46 | 107.44 | 71.63 | 35.81 | 105.05 | 52.53 |

Maximum speed |

rpm | 1200 | 1200 | 2000 | 5000 | 2000 | 5000 |

| Torque constant | N.m/A | 2.52 | 2.52 | 1.68 | 0.84 | 1.68 | 0.84 |

Induced voltage constant |

V/Krpm | 205 | 205 | 127 | 67 | 127 | 67 |

| Rotor inertia | Kg.m^2 | 0.00641 | 0.0084 | 0.00641 | 0.0044 | 0.0084 | 0.00641 |

| IEC #100/112 | 380VAC (Customized DC 24/48/60/72/96V) | ||||||

Rated output |

KW | 2.25 | 3.75 | 5.5 | |||

Rated torque |

N.m |

21.49 |

35.81 | 23.88 | 11.94 | 35.02 | 17.51 |

Rated current |

A | 4.90 | 8.17 | 8.17 | 8.17 | 20.87 | 11.98 |

Rated speed |

rpm | 1000 | 1000 | 1500 | 3000 | 1500 | 3000 |

| Peak torque | N.m | 64.46 | 107.44 | 71.63 | 35.81 | 105.05 | 52.53 |

Maximum speed |

rpm | 1200 | 1200 | 2000 | 5000 | 2000 | 5000 |

| Torque constant | N.m/A | 4.38 | 4.38 | 2.92 | 1.46 | 1.68 | 1.46 |

Induced voltage constant |

V/Krpm | 355 | 355 | 205 | 116 | 205 | 116 |

| Rotor inertia | Kg.m^2 | 0.00641 | 0.0084 | 0.00641 | 0.0044 | 0.0084 | 0.00641 |

Q:

Motor has been running then fails to start,what to do?

A:

Likely cause: Fuse or circuit breaker is tripped.

What to do: Replace the fuse or reset the breaker.

Likely cause: Armature is shorted. Motor may make a humming noise and the circuit breaker or fuse will trip.

What to do: Disassemble motor and inspect the armature for a burnt coil. Inspect the commutator for burnt bars. If this condition exists, the motor needs to be replaced.

Likely cause: The brushes may be worn down too far and no longer make contact with the commutator.

What to do: Check the brushes to make sure that they are still making contact with the commutator. Contact manufacturer for brushes.

Likely cause: Controller may be defective.

What to do: Verify voltage is coming out of the controller.

Q:

On initial installation, motor fails to start up,what to do?

A:

Likely cause: Motor is incorrectly wired

What to do: Verify that the motor is wired correctly.

Likely cause: No output power from controller.

What to do: Measure voltage coming from the controller.

Likely cause: Motor is damaged and the armature is rubbing against the magnets.

What to do: Disassemble motor and see if the armature can be realigned by reassembly. Motor may have to be replaced.

Q:

Motor takes too long to accelerate,what to do?

A:

Likely cause: Motor controller not properly set.

What to do: Adjust the acceleration trim pot of the controller.

Likely cause: Brushes are worn.

What to do: Verify brush length.

Likely cause: Bearings may be defective.

What to do: Inspect bearings. Noisy or rough bearings should be replaced.

Q:

Motor runs in the wrong direction,what to do?

A:

Likely cause: Incorrect wiring

What to do: Interchange the two motor leads.

Q:

Motor runs OK but has a clicking noise,what to do?

A:

Likely cause: Suspect a burr on the commutator.

What to do: Remove burr from commutator using a commutator stone.