- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Size:

-

Dia(40/60/80/100/150mm) L(600/1000/1200/2000mm)

-

Material:

-

Stainless steel + ceramic fibre chamber

-

Weight:

-

By Size

-

Voltage:

-

AC:220 ; 50/60Hz

-

Product name:

-

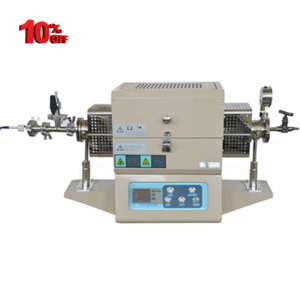

1800c Tube Furnace

-

Application:

-

High temperature heat treatment/sintering/lab physical or chemical

-

Max temperature:

-

1700C

-

Working temperature:

-

1600C(Continuous)

-

Temperature control:

-

30 Segments Programmable + PID Automatic Control

-

Heating element:

-

Mosi2 rod heater

-

Heating Rate:

-

0 ~ 15C/min

-

Power Supply:

-

AC:220 ; 50/60Hz

-

Power:

-

By Size

-

Certificate:

-

CE Certified

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

Pyrocore

-

Model Number:

-

1800c Tube Furnace

-

Place of Origin:

-

Henan, China

-

Size:

-

Dia(40/60/80/100/150mm) L(600/1000/1200/2000mm)

-

Material:

-

Stainless steel + ceramic fibre chamber

-

Weight:

-

By Size

-

Voltage:

-

AC:220 ; 50/60Hz

-

Product name:

-

1800c Tube Furnace

-

Application:

-

High temperature heat treatment/sintering/lab physical or chemical

-

Max temperature:

-

1700C

-

Working temperature:

-

1600C(Continuous)

-

Temperature control:

-

30 Segments Programmable + PID Automatic Control

-

Heating element:

-

Mosi2 rod heater

-

Heating Rate:

-

0 ~ 15C/min

-

Power Supply:

-

AC:220 ; 50/60Hz

-

Power:

-

By Size

-

Certificate:

-

CE Certified

Product Description

This is a CE certified high temperature tube furnace, its maximum working temperature is 1600 ℃, the rated power is 5.2KW. the furnace body adopts double-layer air-cooling mechanism, the furnace burns to the highest temperature, the surface temperature of the shell is less than 60 degrees Celsius, the heat preservation material adopts vacuum adsorption moulding of alumina fibre inorganic material, free of dirt, clean, beautiful. The two ends of the flange with support, reduce the weight of the furnace pipe, to ensure that the service life of the furnace pipe. Mature technology, reliable quality, uniform temperature field, reasonable structure.

Application areas: widely used in semiconductors, nanomaterials, carbon fibre, graphene and other new materials, new process areas.

Specification

|

|

1200c tube furnace

|

1400c tube furance

|

1800c tube furnace

|

||

|

Heating Element

|

resistance wire

|

Sic rod heater

|

Mosi2 rod heater

|

||

|

Max. Temperature

|

1200℃

|

1400℃

|

1700℃

|

||

|

Long-term working temperature

|

1100℃

|

1300℃

|

1600℃

|

||

|

Temperature control

|

±1

|

|

|

||

|

Heating rate

|

0-15℃/Min

|

|

|

||

|

Tube Size

|

φ40/60/80/100/150mm L600/1000/1200/2000mm

(Other sizes can be customized)

|

|

|

||

|

Controllable Temperature Zone

|

1-4 Optional heating zone

|

|

|

||

|

vacuum

|

Mechanical pump 10

-1

pa / Molecular pump 10

-3

pa

|

|

|

||

Product features

1、Using silicon molybdenum rod heater densely spread in the furnace chamber, the temperature field is uniform, the constant temperature zone is super long;

2、Using double shell structure and with air-cooling system;

3、Reasonable structure, simple and convenient experimental operation;

4、Configuration of flange support frame, reducing the weight of the furnace body;

5、the use of high-purity alumina as a furnace material, the surface of the furnace chamber is coated with high-temperature alumina coating imported from the United States can improve the heating efficiency and the service life of the furnace chamber.

Temperature control system:

1. Fuzzy PID control and self-tuning regulation

2. Intelligent 30-segment programmable control, according to different customer needs to set the temperature rise and fall procedures

3. With over-temperature and broken-couple alarm function.

4.K-type thermocouple, temperature control accuracy ±1℃.

In addition to the standard 1200/1400/1800c Vacuum Atmosphere Furnaces, we offer a wide range of Multi-station/Sliding Tube Furnaces and Vertical or Horizontal Tube Furnaces, etc. If you would like to obtain the most suitable furnace for your use, please contact us to discuss further details.

Hot Searches