- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

3

-

Weight (KG):

-

2000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Item:

-

common wire nail machine

-

Function:

-

Making different size nails

-

Control system:

-

Automatic

-

Voltage:

-

380v or as required

-

Motor:

-

Can customise

-

Using Life:

-

More than 15 working years

-

End Product:

-

Quality Nails

Quick Details

-

Marketing Type:

-

Hot Product 2021

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huarui

-

Power (kW):

-

3

-

Weight (KG):

-

2000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Item:

-

common wire nail machine

-

Function:

-

Making different size nails

-

Control system:

-

Automatic

-

Voltage:

-

380v or as required

-

Motor:

-

Can customise

-

Using Life:

-

More than 15 working years

-

End Product:

-

Quality Nails

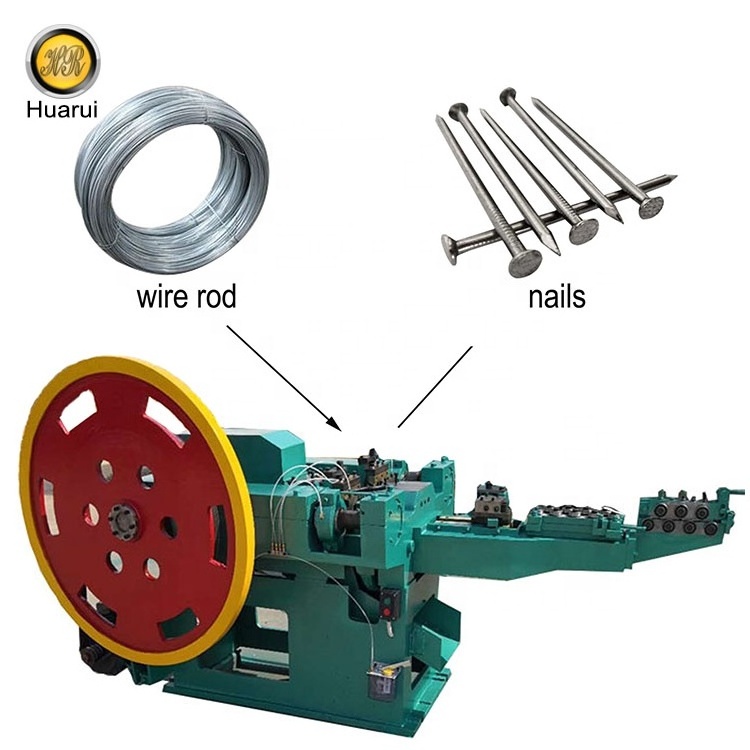

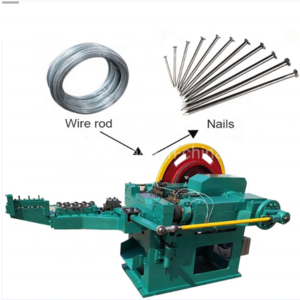

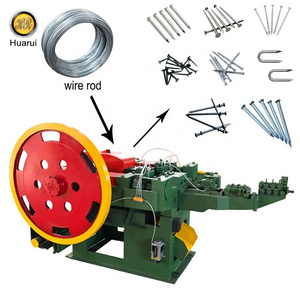

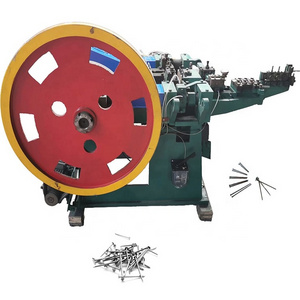

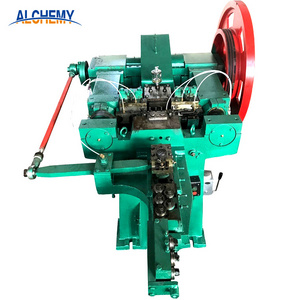

Automatic Common Wire Nail Making Machine

Process flow: Steel wire --wire drawing--nail making--nail polishing--fiished nails.

The diameter of Q195 steel/Q235 steel is 6.5mm in the market. The user can draw the steel wire by wire drawing machine. After get the diameter of steel wire you need, and then begin to make nails by automatic nail making machine.

Combined Wire Drawing Machine

Function: Reduce the diameter of wire , then the user can get the diameter that you need.

|

Model No. |

Max inlet diameter |

Min outlet diameter |

Motor Power |

|

LS560 |

6.5mm |

2.0mm |

11/15kw/set |

|

Remarks: this machine comes with descaling machine and discharging machine |

|||

Outstanding adavantages of our wire drawing machine:

1). The gearbox of our wire drawing machine is using level 3 Hard magnetic surface magnet-wheel.

2). The winding drums of our wire drawing macine are made of 45# steel after hypertonic carbon treatment which is very hard and wear-resistant, no need to change forever.

Auxiliary equipments of wire drawing machine

The left: This is pointing rolling machine, to sharpen the head of the wire , then it can enter the wire drawing machine. It can process the wire diameter ≤8mm .

The right: This is butt welding machine, to weld two wires coil together .

When one wire coil finish drawing, this machine can connect the next wire coil to continue to be drawn by the wire drawing machine. It can weld the wire diameter between 2-8mm .

Tip: If you buy suitable diameter of wire rods directly from the market, then no need wire drawing machines as well as the point rolling machine and butt welding machi ne .

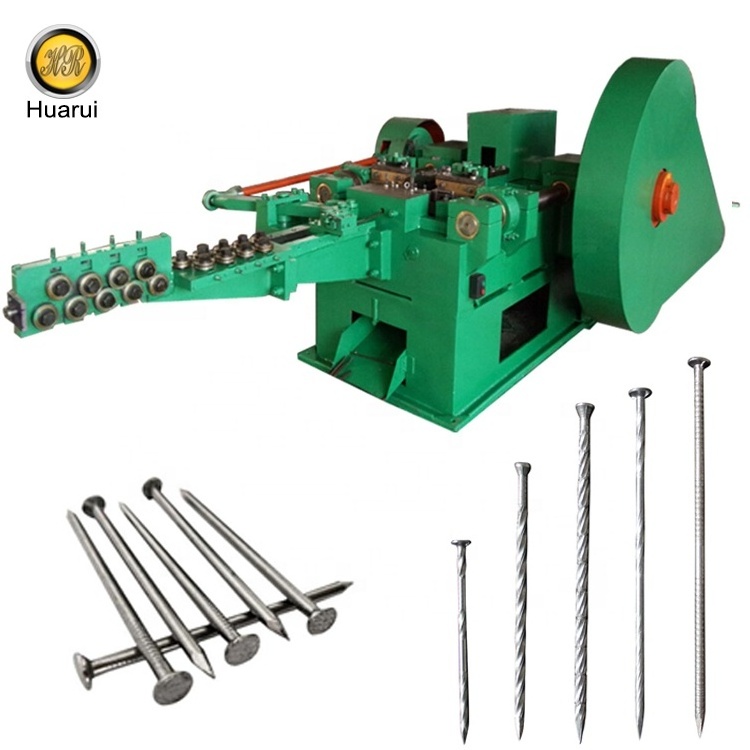

Z94C series automatic nail making machine

Function: This machine adopts piston structure to ensure the high working speed, low noise and less chance of impact characteristics, especially can make excellent quality YouMao nail and other specialshaped nail which are suitable for high speed studs for welding machine and nail gun.

Main Specification:

|

Model |

Diameter of nails |

Length of nails |

Designed speed |

Motor |

Dimension (L*W*H) |

Weight |

|

Z94-1C |

0.9-16.mm |

9-25mm |

450pcs/min |

1.5kw |

1.5*1.3*1.1m |

1.2tons |

|

Z94-2C |

1.2-2.8mm |

16-50mm |

380pcs/min |

2.2kw |

1.7*1.3*1.4m |

1.45tons |

|

Z94-3C |

1.8-3.5mm |

30-75mm |

320pcs/min |

3kw |

2.0*1.4*1.4m |

1.8tons |

|

Z94-4C |

2.8-4.5mm |

50-100mm |

260pcs/min |

4kw |

2.2*1.6*1.6m |

2tons |

|

Z94-4C (2) |

2.8-5mm |

50-120mm |

260pcs/min |

4kw |

2.3*1.6*1.3m |

2.1tons |

|

Z94-5.5C |

3.8-5.5mm |

75-150mm |

220pcs/min |

5.5kw |

2.5*1.8*1.5m |

2.3tons |

Outstanding adavantages of our nail making machine:

1. The machine is made from bearing , which make the machine less impact and low noise.

2. The machine can feed the raw material automatically .

3. The machine can add lubricating oil automatically .

4. The machine adopts piston structure to ensure the high working speed, low noise and less chance of impact characteristics, especially can make excellent quality YouMao nail and other special shaped nail which are suitable for high speed studs for welding machine and nail gun.

5. One model nail making machine can make diff erent size of nails .

6. The warranty time of our machines is 2 years .

Nail making machine in our factory:

Auxiliary equipments of nail making machine:

Cutter grinder.

Function: This is the auxiliary equipment of nail making machine, when the nail cutter of the nail making machine is not so sharp, the user can use this machine to sharpen it.

Remark : our cutter grinding machine includes 1 set diamond grinding wheel , which can grind the tungsten carbides knife.

Nail polishing machine

Function: This machine is auxiliary equipment of nail making machine. When the nails have been made by the nail making machine, it will be not very bright. The user can use this machine to polish the nails to let it brighter, smoother and anti-rust.

Function : use to polish the nails to let nails brighter, smoother and anti-rust .

|

Model No. |

Motor Power |

Dimension(L*W*H) |

Capacity |

|

SD-400 |

2.2kw |

1.64*0.9*1.0m |

400kg |

|

SD-1000 |

7.5kw |

2.0*1.5*1.4m |

1000kg |

How to make nails:

S tep1: Prepare the suitable diameter steel wire rods.

Step2: Use the nail making machine to produce nails.

Step3: Use the nail polihsing machine to polish nails, then finished.

Newest loading pictures:

Finished nails

Success cases:

Contact

Sales manager: Angela

Wechat/whatsapp/tel:+008615936355361