- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MLB

-

Model Number:

-

Fiberglass Putty

-

Product Name:

-

Fiberglass Putty

-

Manufacturer:

-

OEM&ODM

-

Shelf life:

-

2 Years

-

Certificate:

-

ISO14001, ISO9001, MSDS

-

Packing:

-

1kg*12can, 4kg*6can

-

Advantage:

-

High glossy and high hardness.

-

Drying time:

-

5-10 mins

-

Delivery Time:

-

10-20 days after order confirmed

-

Service:

-

Free Samples

Quick Details

-

CAS No.:

-

N/A

-

Other Names:

-

Fiberglass Putty

-

MF:

-

No

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MLB

-

Model Number:

-

Fiberglass Putty

-

Product Name:

-

Fiberglass Putty

-

Manufacturer:

-

OEM&ODM

-

Shelf life:

-

2 Years

-

Certificate:

-

ISO14001, ISO9001, MSDS

-

Packing:

-

1kg*12can, 4kg*6can

-

Advantage:

-

High glossy and high hardness.

-

Drying time:

-

5-10 mins

-

Delivery Time:

-

10-20 days after order confirmed

-

Service:

-

Free Samples

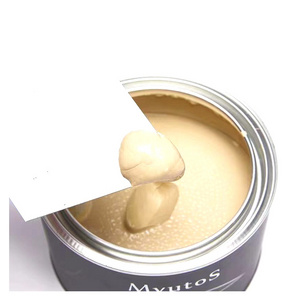

FIBERGLASS PUTTY

1. Product composition

Unsaturated polyester resins, modified resins, pigments, fillers, anti-settling materials, special additives and special BPO curing agents are formulated at a ratio of 100:2.

2.Product Features

The multi-functional series polyester putty has more fine body, less blisters, smooth and fine coating film, and finer coating structure. It can be used as the final fine scraping polyester putty. After fine grinding, no joints will be found on the edge part, and it has conventional Advantages of polyester putty: easy to apply and scratch, fast drying at room temperature, easy to polish, not to collapse, good filling, strong adhesion, high temperature resistance, good vertical construction, no sagging, good flexibility and matching, etc. This product is fast in construction , convenient, and greatly improve the construction efficiency.

3. Construction Scope

Suitable for a variety of metals (such as bare iron, stainless steel, aluminum, galvanized sheet, etc.), glass fiber reinforced plastic, old paint film, wood, and various two-component primer surfaces.

4.Main technical data sheet

Main putty indicator

|

Name

|

Project

|

Technical indicators

|

Test standards

|

|

Putty component

|

State

Color appearance |

No crusting, no lumps, no visible particles

Light yellow paste |

Visual inspection

Visual inspection

|

|

|

|

|

|

Coating performance index

|

Project

|

Technical indicators

|

Test standards

|

|

Putty color and appearance

|

Pale yellow, even after scratching

|

Visual inspection

|

|

dry condition

|

No obvious particles, no scratches, no cracks after drying

|

|

|

Dry sanding time h(25℃) ≤

|

1

|

GB/T1728

|

|

Thickness cm

|

9~12

|

GB/T1749

|

|

Gel time (pot life) min ≥

|

3

|

GB/T1728

|

|

Adhesion MPa ≥

|

5

|

GB/T5210

|

|

Flexibility mm ≤

|

50

|

GB/T1748

|

|

Impact strength cm ≥

|

18

|

GB/T1732

|

5.Construction reference:

(1)Mix the putty and hardener at a ratio of 100:1-3 (to make the color consistent), and use it up within the gel time.

(2)Scrape the adjusted polyester putty on the polished two-component primer or the treated sheet metal surface. If thick coating is required, it is best to scrape it thinly to the required thickness. If there are air bubbles infiltrated when smearing, it must be thoroughly scraped with a scraper to ensure good adhesion.

6.Notes:

(1)Once the putty is mixed with hardener, it cannot be put into the tank again, and it should be covered immediately after use to avoid the deterioration of the putty caused by the volatilization of the solvent.

(2)The consistency of the putty and the gel time can be adjusted according to customer requirements.

(3)his product cannot be used for corrosive paints on metal surfaces, synthetic resins or nitrocellulose primers, and one-component acrylic primers, and it is not recommended to spray topcoat directly on the surface of this product.

(4)The effective storage period is twelve months from the date of production. (After the shelf life is exceeded, it will be confirmed by standard inspection. If it is qualified, it can still be used.)

Suitable for galvanized substrates on cars.

Excellent curing hardness, good adhesion, filling and sanding

Both wet and dry sanding ability property.

AUTOMATIC MIXER

Finished paint formulation system for automotive

paint to improve the preparation efficiency of finished paint for you

Car paint color card

Can be customized according to your needs

Hot Searches