- Product Details

- {{item.text}}

Quick Details

-

Operation speed:

-

1S for 3m, 1.5S for 3.5m

-

Remote Control Distance:

-

<50m

-

Working temperature:

-

-35°C to +95°C

-

G.W:

-

60KG

-

Power supply(Volatage):

-

AC 100-240V 50-60HZ

-

Motor power:

-

90W/80W

-

Input interface:

-

switch signal

-

Number of remotes:

-

≤200

-

communication:

-

RS485/TCP/IP(optional )

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SECUERA or OEM

-

Color option:

-

Orange

-

Operation speed:

-

1S for 3m, 1.5S for 3.5m

-

Remote Control Distance:

-

<50m

-

Working temperature:

-

-35°C to +95°C

-

G.W:

-

60KG

-

Power supply(Volatage):

-

AC 100-240V 50-60HZ

-

Motor power:

-

90W/80W

-

Input interface:

-

switch signal

-

Number of remotes:

-

≤200

-

communication:

-

RS485/TCP/IP(optional )

Product Description

Specification

Description:

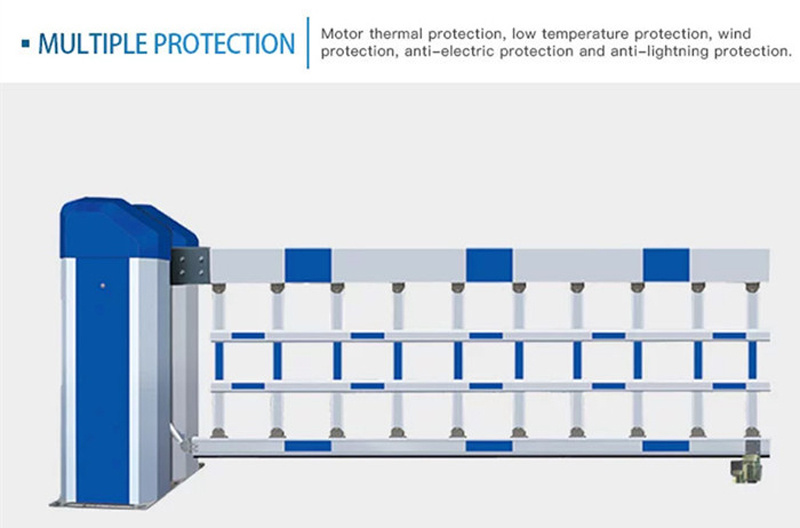

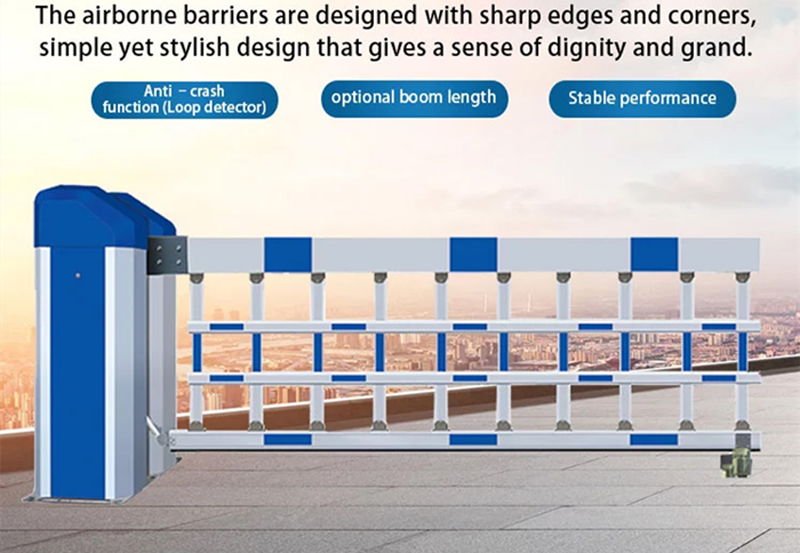

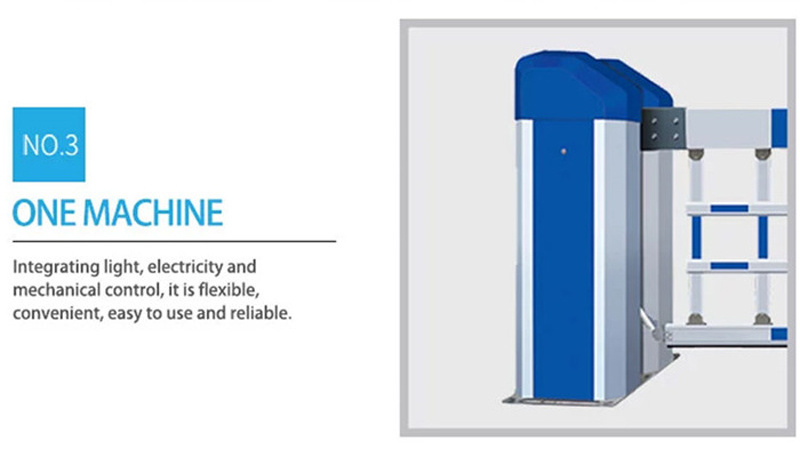

* The traffic barrier is widely used for the facilities of parking, traffic or toll system.

* Arms can be chosen from 3 meters to 6 meters.

* This type of barrier could match with direct boom( pole), fold boom Or fence boom.

* Advanced manual release .Clutch key can be used to open the clutch when electricity is cut off.

* All the process is soft without any noise and shaking.

* This barrier gate has many input terminals for photocell, Air wave switch, loop detector, back-up battery(for DC Motor), toll

gate system and output terminals for lamp.

* Housing color: yellow, red, blue, orange, white (optional).

* Boom arm direction can be chosen leftward to rightward.

* Auto warming up,suitable for cold environment.

* Controlling way: wireless or wiring multiple push button for OPEN, CLOSE, STOP function.

* Arms can be chosen from 3 meters to 6 meters.

* This type of barrier could match with direct boom( pole), fold boom Or fence boom.

* Advanced manual release .Clutch key can be used to open the clutch when electricity is cut off.

* All the process is soft without any noise and shaking.

* This barrier gate has many input terminals for photocell, Air wave switch, loop detector, back-up battery(for DC Motor), toll

gate system and output terminals for lamp.

* Housing color: yellow, red, blue, orange, white (optional).

* Boom arm direction can be chosen leftward to rightward.

* Auto warming up,suitable for cold environment.

* Controlling way: wireless or wiring multiple push button for OPEN, CLOSE, STOP function.

Specifications:

|

Model No

|

|

SE-BG20

|

|

|

|||

|

Working voltage

|

|

24V+10%/50HZ

|

|

|

|||

|

Motor power

|

|

140W

|

|

|

|||

|

Chassis color

|

|

black, yellow, gold

|

|

|

|||

|

Ambient temperature

|

|

-30℃~80℃

|

|

|

|||

|

Relative humidity

|

|

≤95%

|

|

|

|||

|

Length of the barrier rod

|

|

can be customized according to the actual situation on site

|

|

|

|||

|

Lift time

|

|

generally 1.5~6S

|

|

|

|||

|

Height of the center of the brake lever from the ground

|

|

850mm

|

|

|

|||

|

Remote control distance

|

|

≤40m

|

|

|

|||

|

Protection class

|

|

IP44

|

|

|

|||

|

Input interface

|

|

+12V level signal or pulse signal greater than 100ms; drive current: less than 10mA

|

|

|

|||

|

Chassis size

|

|

L370*W290*H980mm

|

|

|

|||

|

Carton size

|

|

420*390*1080mm

|

|

|

|||

|

Chassis weight

|

|

50KG

|

|

|

|||

Installation Notes:

* Open the packing box and check the relevant random spare parts according to the spare parts list.

* Determine the installation position of the main gate of the gate according to the left and right direction of the selected gate

and the actual situation of the installation site. For non-concrete foundations or when the main body of the road gate is

installed with a slope, it is recommended to build a concrete foundation, and it should be ensured that the foundation and the

foundation are firmly combined, and the verticality of the main body of the main body of the road gate to the horizontal plane

is less than 1°.

* According to the location of the control room or guard box, lay the power line and control line pipe according to the relevant

regulations in “GB232 Electrical Installation Engineering Construction and Acceptance Specification” (it is recommended that

the power line and control line be put in different line pipes).

* Install expansion screws (determined according to the accessories actually equipped in the list) at the installation position

of the main gate of the gate, and fix the main machine of the gate firmly before use.

* Use the crank handle to shake the brake lever to the horizontal position, determine the installation position of the fork lever

at the end of the brake lever, and fix the fork lever firmly with screws (no need to install if there is no fork lever).

* Carefully check the wiring diagram, connect the power cord and related control lines to the gate control board, and then

tighten and debug after confirming that they are correct.

Note: The above operations should be performed under the condition of power off.

Specific Operation of Boom Barrier Gate:

* (1) Line pre-buried

The position of the chassis is determined according to the customer’s requirements. If the concrete base needs to be poured, it

can be completed in advance (the size of the base is about 100-150mm larger than the outer dimension of the bottom of the

gate). Pre-embed or excavate cable trenches between guard boxes, bury line pipes, and penetrate 3X1.5 square millimeters of

power lines and 4X0.5 square millimeters of control lines used for equipment. After confirmation, backfill concrete.

* (2) Fixed chassis

Put the chassis in a fixed position, open the chassis door, then mark the center of the screw holes on the chassis bottom plate

and the edge of the chassis base, remove the gate, and drill vertically with a drill bit on the marked screw holes (the size of

the drill bit should be the same as that of the chassis). Match the expansion bolts with the equipment), and the depth should

meet the length requirements of the expansion bolts. Move the chassis to its original position, drive in the expansion screws

and fasten them firmly.

* (3) Installation of brake lever

After the gate case is firmly fixed, the gate rod can be installed at the position of the rod handle, tightened with the

provided screws, and ensure that the gate rod is not inclined. If you need to install the fork rod, after debugging the

vertical and horizontal states, use the crank handle to shake the brake rod to the horizontal position, determine the

installation position of the fork rod at the end of the brake rod, and fix the fork rod firmly with screws (No need to install

if there is no fork lever).

* (4) Installation of peripheral equipment

The gate is installed firmly, and after the debugging is completed, according to the needs of the customer, the chassis circuit

and the control circuit of the related peripheral equipment can be connected according to the wiring diagram of the gate

control board, and related debugging can be carried out.

* Open the packing box and check the relevant random spare parts according to the spare parts list.

* Determine the installation position of the main gate of the gate according to the left and right direction of the selected gate

and the actual situation of the installation site. For non-concrete foundations or when the main body of the road gate is

installed with a slope, it is recommended to build a concrete foundation, and it should be ensured that the foundation and the

foundation are firmly combined, and the verticality of the main body of the main body of the road gate to the horizontal plane

is less than 1°.

* According to the location of the control room or guard box, lay the power line and control line pipe according to the relevant

regulations in “GB232 Electrical Installation Engineering Construction and Acceptance Specification” (it is recommended that

the power line and control line be put in different line pipes).

* Install expansion screws (determined according to the accessories actually equipped in the list) at the installation position

of the main gate of the gate, and fix the main machine of the gate firmly before use.

* Use the crank handle to shake the brake lever to the horizontal position, determine the installation position of the fork lever

at the end of the brake lever, and fix the fork lever firmly with screws (no need to install if there is no fork lever).

* Carefully check the wiring diagram, connect the power cord and related control lines to the gate control board, and then

tighten and debug after confirming that they are correct.

Note: The above operations should be performed under the condition of power off.

Specific Operation of Boom Barrier Gate:

* (1) Line pre-buried

The position of the chassis is determined according to the customer’s requirements. If the concrete base needs to be poured, it

can be completed in advance (the size of the base is about 100-150mm larger than the outer dimension of the bottom of the

gate). Pre-embed or excavate cable trenches between guard boxes, bury line pipes, and penetrate 3X1.5 square millimeters of

power lines and 4X0.5 square millimeters of control lines used for equipment. After confirmation, backfill concrete.

* (2) Fixed chassis

Put the chassis in a fixed position, open the chassis door, then mark the center of the screw holes on the chassis bottom plate

and the edge of the chassis base, remove the gate, and drill vertically with a drill bit on the marked screw holes (the size of

the drill bit should be the same as that of the chassis). Match the expansion bolts with the equipment), and the depth should

meet the length requirements of the expansion bolts. Move the chassis to its original position, drive in the expansion screws

and fasten them firmly.

* (3) Installation of brake lever

After the gate case is firmly fixed, the gate rod can be installed at the position of the rod handle, tightened with the

provided screws, and ensure that the gate rod is not inclined. If you need to install the fork rod, after debugging the

vertical and horizontal states, use the crank handle to shake the brake rod to the horizontal position, determine the

installation position of the fork rod at the end of the brake rod, and fix the fork rod firmly with screws (No need to install

if there is no fork lever).

* (4) Installation of peripheral equipment

The gate is installed firmly, and after the debugging is completed, according to the needs of the customer, the chassis circuit

and the control circuit of the related peripheral equipment can be connected according to the wiring diagram of the gate

control board, and related debugging can be carried out.

Packing & Delivery

Hot Searches