- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/ 380V/ 400V/ 440V/ 480V

-

Power:

-

According to the model

-

Dimension(L*W*H):

-

According to the layout

-

Weight (KG):

-

1200

-

Marketing Type:

-

New product 2022

-

Evaporation Capacity(kg/h):

-

Customized

-

Input material:

-

Filter cake, block, powder

-

Output product:

-

Dry powder

-

Inlet air temperature:

-

140~220 Celsius degree

-

Outlet air temperature:

-

60~110 Celsius degree

-

Inlet air filter:

-

Pre, middle and high efficient filter

-

Feeding system:

-

Screw feeder

-

Product collecting system:

-

Cyclone separator

-

Dust removing system:

-

Bag filter & Wet scrubber

-

Control system:

-

Touch screen/ Button type

-

After sales service:

-

Engineer go to guide installation and commissioning

Quick Details

-

Type:

-

Flash Drying Equipment

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Bole Tech

-

Voltage:

-

220V/ 380V/ 400V/ 440V/ 480V

-

Power:

-

According to the model

-

Dimension(L*W*H):

-

According to the layout

-

Weight (KG):

-

1200

-

Marketing Type:

-

New product 2022

-

Evaporation Capacity(kg/h):

-

Customized

-

Input material:

-

Filter cake, block, powder

-

Output product:

-

Dry powder

-

Inlet air temperature:

-

140~220 Celsius degree

-

Outlet air temperature:

-

60~110 Celsius degree

-

Inlet air filter:

-

Pre, middle and high efficient filter

-

Feeding system:

-

Screw feeder

-

Product collecting system:

-

Cyclone separator

-

Dust removing system:

-

Bag filter & Wet scrubber

-

Control system:

-

Touch screen/ Button type

-

After sales service:

-

Engineer go to guide installation and commissioning

Product Description

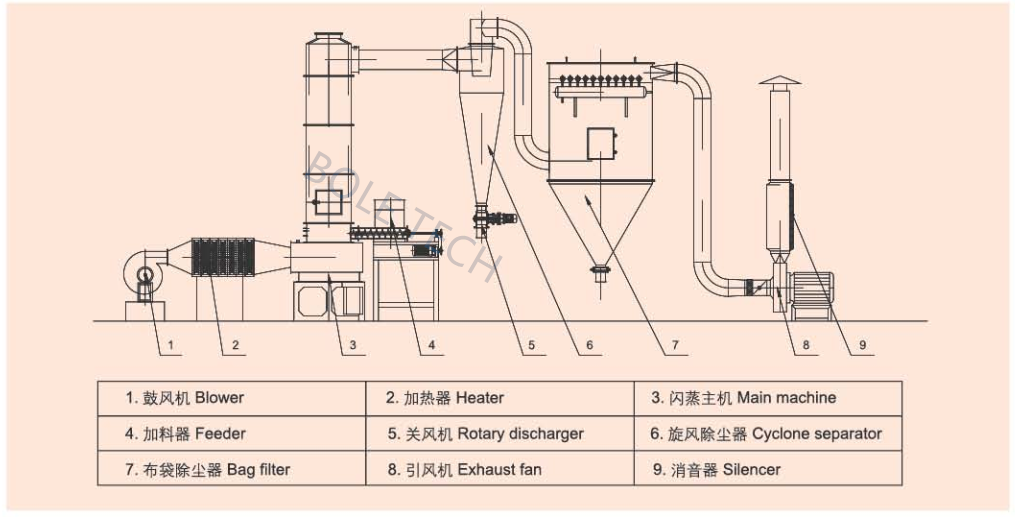

Description of spin flash dryer:

XSG Spin Flash Dryer is widely used for drying materials such as paste, cake shape, powder, granules material, etc. It is a new type high drying efficiency and low energy consumption equipment that researched and developed by our company. It is widely used in nutriceutical industry, food industry, chemical industry, environmental protection industry, new energy industry and so on.

Work principle of spin flash dryer:

Hot air enters the stirring part of drying chamber from the bottom, material is stirred by stirring device and then the hot air

exerts strong shearing, blowing, floating and rotating effect to material. Therefore material is crushed by centrifugal, shearing, impacting and friction effect. It strengthens the heat exchanging process. In the bottom of drying chamber, big and damp granules are crushed by stirring device, the particles with low moisture content and small size are lifted by rotary air stream, and be further dried. Gas and solid two phases rotary flow, inertia of solid phase is bigger than gas phase, the relative velocity between gas phase and solid phase is high, heat exchanging efficiency is strengthened, so the drying intensity of this machine is high.

exerts strong shearing, blowing, floating and rotating effect to material. Therefore material is crushed by centrifugal, shearing, impacting and friction effect. It strengthens the heat exchanging process. In the bottom of drying chamber, big and damp granules are crushed by stirring device, the particles with low moisture content and small size are lifted by rotary air stream, and be further dried. Gas and solid two phases rotary flow, inertia of solid phase is bigger than gas phase, the relative velocity between gas phase and solid phase is high, heat exchanging efficiency is strengthened, so the drying intensity of this machine is high.

Features of spin flash dryer:

1. Different kinds of feeding device can be chose, feeding is continuous and stable, there is on bridge phenomenon.

2. There is special cooling device at the bottom of dryer, it can avoid the material deteriorate in the bottom high temperature area.

3. Special air sealing device and bearing cooling device and make the life of transmission device longer effectively.

4. There is special air distributing device, it reduces the resistance of equipment, and make the air speed in drying chamber be balanced.

5. There are classification rings and turbojet plates in the drying chamber, fineness and final moisture of product and be

adjusted and controlled.

6. In the drying chamber air speed is fast, drying time is short, it can avoid material stick on the wall and deterioration

effectively.

2. There is special cooling device at the bottom of dryer, it can avoid the material deteriorate in the bottom high temperature area.

3. Special air sealing device and bearing cooling device and make the life of transmission device longer effectively.

4. There is special air distributing device, it reduces the resistance of equipment, and make the air speed in drying chamber be balanced.

5. There are classification rings and turbojet plates in the drying chamber, fineness and final moisture of product and be

adjusted and controlled.

6. In the drying chamber air speed is fast, drying time is short, it can avoid material stick on the wall and deterioration

effectively.

Details Images

XSG-10 for drying starch

XSG-12 for drying monosultap

XSG-3 for drying Soybean dregs

XSG-5 for drying molecular sieve

Screw feeding system and machine base

Upper box of Pulse bag filter

Product Parameters

|

Model

|

XSG-4

|

XSG-6

|

XSG-8

|

XSG-10

|

XSG-12

|

XSG-14

|

XSG-16

|

|

Inner diameter (mm)

|

400

|

600

|

800

|

1000

|

1200

|

1400

|

1600

|

|

Air volume (m

3

/h)

|

2100

|

4500

|

7500

|

12000

|

18000

|

24000

|

30000

|

|

Water evaporation (kg/h)

|

60

|

130

|

240

|

400

|

610

|

800

|

1000

|

|

Installed power (kW)

|

25

|

37

|

48

|

75

|

85

|

98

|

135

|

|

Max. height (m)

|

4.6

|

5.5

|

6.0

|

6.5

|

7.0

|

7.5

|

8.5

|

|

Occupied area (m

2

)

|

19

|

26

|

34

|

45

|

58

|

76

|

110

|

Hot Searches