When filtering finished, the cakes can be discharged into this storage hopper for easier collection and transprotation. The hopper

dimension can be customized. There are two methods for opening: electrucal or pneumatic.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Power:

-

4.0KW

-

Weight:

-

12494 kg

-

Dimension(L*W*H):

-

7315*1900*1630 mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Automatic Slurry Water Filter Press For Sale

-

Application:

-

Drinking;Dyeing; Chemical; Mining

-

Filter Area:

-

180m2

-

Plate QTY:

-

65 Pcs

-

Plate Size:

-

1250*1250mm

-

Chamber Volume:

-

2619L

-

Filter Precision:

-

30-500 um

-

Material:

-

Carbon Steel

-

Description:

-

Solid-liquid Separation Filtering Machine

Quick Details

-

Marketing Type:

-

New Product 2021

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DZ

-

Voltage:

-

Customized

-

Power:

-

4.0KW

-

Weight:

-

12494 kg

-

Dimension(L*W*H):

-

7315*1900*1630 mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Automatic Slurry Water Filter Press For Sale

-

Application:

-

Drinking;Dyeing; Chemical; Mining

-

Filter Area:

-

180m2

-

Plate QTY:

-

65 Pcs

-

Plate Size:

-

1250*1250mm

-

Chamber Volume:

-

2619L

-

Filter Precision:

-

30-500 um

-

Material:

-

Carbon Steel

-

Description:

-

Solid-liquid Separation Filtering Machine

Product Information

Automatic Slurry Water Filter Press For Sale

Filter Press Working Principle:

1.Filter press consists of frame, filter plate, pressing system(manual, mechanical or hydraulic) and electric control cabinet.

2. Frame consists of base, push plate, tail plate, girder and supports the pressing device and filter plates.

3. Filter plates are installed on girder between tail plate and push plate, with filter cloth sandwiched in them.

4. In operation, the pressing device(cylinder piston rod or screw) drives the push plate to press the filter plates and filter

cloth between push plate and tail plate. Filter chambers are formed between pressed filter plates and materials get into the filter chambers through the feeding port in tail plate. Solid particles are trapped in filter chambers form into cakes, while liquid is discharged out of the machine through press cake and filter cloth. To wash the press cakes, washing water can be introduced through the washing port in the tail plate. In simimlar way, to put the filter cakes dry, compressed air can be go through the washing port.

5. Plate and frame type filter press in structure, except the filtering part that consists of one plate, one frame and filter

cloth, with filter chamber between plate and frame.

6. Liquid stream of filter press can be divided into exeternal stream and internal stream, exeternal stream refers to that the

filtrate is discharged directly from the outlet port of filter plate; internal stream refers to that the filtrate from various

filter plate is collected before being discharged out of the filter port.

Cake Storage Hopper:

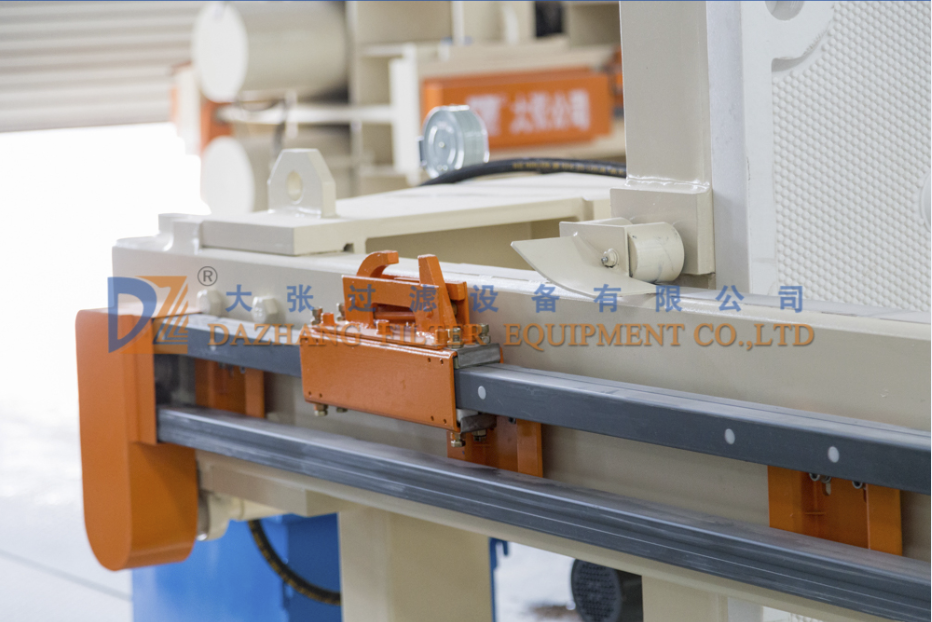

Automatic Cloth Washing System:

When the filter cloth was blocked, it can use the cloth washing system to clean the blocked solid by high pressure waster, so that increase the filtering speed and enlarge the lift-span.

The device have two types: single pole washing system and double poles washing system.

The device have two types: single pole washing system and double poles washing system.

Automatic Cloth Inclining System:

While cake discharging, it can increase the angle of filter cloth and make the cloth form a inverted"V" shape, at the same time, the springs on the filter cloth will shake the cakes and make it discharging automatically.

Automatic Plate Shaking System:

It is drived by pneumatic controller. While cake discharging of auto-plate shifer on the filter press, it will shake one side handle of filter plate automatically, and make plate shaking up and down, and force cake discharging automatically.

Drip Tray Set:

The drip tray beneath the filter press. While filtering, the tray closed, so the leakage or filtrate will be guided to the channels on both sides. While cake discharging, the tray will be open to guide the cakes.

Belt Conveyor:

According to usage, belt conveyor could be distinguish into types: heavy and light. Heavy belt conveyor is normally utilized in sewage treatment industry.

The belt conveyor beneath the filter press, it is possible for assemble the filter press with bearing beam, heavy duty support leg and cake guiding devices assembled.

|

Chamber Filter Press

|

Model:

|

XMZ180-1250

|

Filter Area:

|

180 m2

|

|

|

Plate Size:

|

1250*1250mm

|

Plate QTY:

|

65 Pcs

|

|

|

Chamber Volume:

|

2619L

|

Cake Thickenss:

|

30mm

|

|

|

Weight:

|

12494 kg

|

Dimensions:

|

7315*1900*1630

mm

|

Specification

Program controlled automatic chamber/recessed filter press can carry out multiple operations, such as:filter plate pressing, liquid collector plate open/close, filter plate releasing, filter plate withdrawing, cloth washing, with micro chip controller, PLC, touch screen installed. You can also deal with all the works by remote control of this machine.

With mainpulator assembled and meanwhile the hydraulic cyclinder enhanced. Program controlled automatic chamber/recessed filter press turns to be an energy-efficient filter press, it could discharge more filter cakes as before.

This type can apply to the industries which handle with easily dehydrated material and high frequency operation. Compact structure, stable performance, efficiency and economy are the advantages of this type.

The rapid unloading system can increase the speed of cake discharging efficiency 3-6 times, especially for the large quantity of filter plate press or high frequency operation devices, it's much outstanding.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided. For small machine, wooden package, for big machine, nude package, spare parts wooden package.

Hot Searches