- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ACERETECH

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

2230*1630*3450mm

-

Power (kW):

-

45

-

Weight (T):

-

5

-

Name:

-

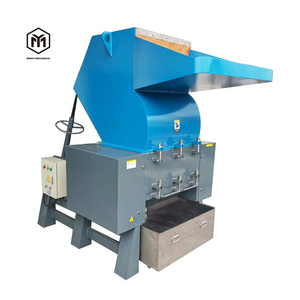

plastic crusher machine

-

Fits for:

-

almost all kinds of plastics

-

Final product:

-

flakes 40-80 mm

-

Control:

-

Siemens P.L.C Control

-

Business type:

-

Manufacturer

-

Sample/Service Manual:

-

Available

-

Factory location:

-

2 Hours Drive From Shanghai

-

Color:

-

Customers' Demand

-

Hydraulic driving ram:

-

Included, speed adjustable

-

Hydraulic screen cradle:

-

Included

Quick Details

-

Max.Production Capacity (kg/h):

-

2000

-

Place of Origin:

-

Jiangsu, China

-

Production Capacity (kg/h):

-

200 - 2000 kg/h

-

Brand Name:

-

ACERETECH

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

2230*1630*3450mm

-

Power (kW):

-

45

-

Weight (T):

-

5

-

Name:

-

plastic crusher machine

-

Fits for:

-

almost all kinds of plastics

-

Final product:

-

flakes 40-80 mm

-

Control:

-

Siemens P.L.C Control

-

Business type:

-

Manufacturer

-

Sample/Service Manual:

-

Available

-

Factory location:

-

2 Hours Drive From Shanghai

-

Color:

-

Customers' Demand

-

Hydraulic driving ram:

-

Included, speed adjustable

-

Hydraulic screen cradle:

-

Included

Product Description

GF series is a high-efficiency and low energy consumption crusher, specially designed for films, small hollow bottles and PET bottles. According to the characteristics of different materials, the crusher is equipped with a variety of rotor models for choosing. The diameter of the rotor ranges from 500mm to 800mm. The minimum width of the rotor is 700mm and the maximum is 1600mm. A targeted rotor structure can be designed to achieve the best crushing effect. It adopts a special welding process for the overall steel structure to meet the demand for the materials which are not easily broken. Large rotor bearings, tool holders and rotors are combined with standard V-shaped cutting technology, which is beneficial to improve cutting and recycling efficiency and reduce the dust content in recycled materials.

Aceretech Recyclable Plastics Include

●

Small hollow products

●

HDPE milk bottles

●

PET bottles

● Oil cans

●

Films

Suitable Products

Product Paramenters

|

SPECIFICATIONS

|

|

|

|

|

|

|||||

|

Item

|

unit

|

GF500/700

|

GF700/1000

|

GF700/1200

|

GF800/1600

|

|||||

|

Rotor diameter

|

mm

|

500

|

700

|

700

|

800

|

|||||

|

Rotor width

|

mm

|

700

|

1000

|

1200

|

1600

|

|||||

|

Number of stator knives

|

pcs

|

5*2

|

5*2/7*2

|

5*2/7*2

|

5*4/7*4

|

|||||

|

Number of stator knives

|

row

|

2

|

2

|

2

|

2

|

|||||

|

Chamber size

|

mm

|

500*700

|

700*1000

|

700*1176

|

800*1600

|

|||||

|

Motor power

|

kw

|

45

|

75

|

90

|

160

|

|||||

|

Machine Length

|

mm

|

2230

|

2530

|

2750

|

3150

|

|||||

|

Machine Width

|

mm

|

1630

|

1990

|

2230

|

2710

|

|||||

|

Machine Height

|

mm

|

3450

|

3600

|

3700

|

3900

|

|||||

Product Detail

TOUGH WELDED MACHINE BODY

>>> ACERETECH crusher’s body is made of special high strength welded steel to prevent shell cracking and excessive stress damage while running.

FEEDING

>>> Motor drives of conveyor belt and hauling device cooperate with abb inverter. feeding speed of conveyor belt or roll hauling of is fully automatic.

EASY MAINTENANCE

>>> Optimized crushing chamber, with help of the hydraulic controlling open and close, it’s easy to clean the inner chamber and rapidly replace parts.

STABLE POWERTRAIN

UNIFORM GRINDING

>>> We have more than twenty different knife designs such as double-shear V-shaped cutting. They can achieve uniform particle size and less dust after crushing. Modular cutting chamber. Select suitable knives and screen according to material characteristics.

>>> Alloy steel rotary and fixed knives are made by European supplier.

CUTTING CHAMBER

>>>

The hinged screen frame is convenient for disassembly and assembly of the screen, and can be installed and removed through a separate door without tools.

Company Video

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

● ACERETECH is original manufacturer.

● If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

● The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 15 years

● After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

THE AFTER-SALE SERVICE OF ACERETECH MACHINERY

● After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by the standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

Hot Searches